M.N. MOSKOVSKIY

MODELING OF THE

FRACTIONATION THE STRAW HEAP IN THE ASPIRATION CHAMBER

During a combine

harvesting we have a significant amount of a straw, which is a potential raw material for the production the bedding material

(litter) in the livestock and the poultry. Fractionation with the air flow is one of the main processes of the producing litter.

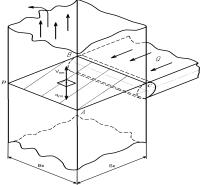

The aim of this research is to develop a new math model of the separation straw heap in the aspiration chamber by using the air flow. We consider a vertical aspiration canal ACPK with given geometric

characteristics: wide BK, depth SK (Figure 1a). Supply

of the straw heap is carried out with a known or defined probabilities density ![]() on the width of the input side and

on the width of the input side and ![]() on the depth [1].We consider an arbitrarily located (below the entry of the granular

material in AcPK) section ABC with the limited size of the chamber (Fig.1b).

on the depth [1].We consider an arbitrarily located (below the entry of the granular

material in AcPK) section ABC with the limited size of the chamber (Fig.1b).

а) b)

Figure. 1. Vertical aspiration chamber

a- diagram of the input material, b-section ABCD, ground mik, in the vertical aspiration canal with the width BK and

depth SK

We define the air flow

speed by the using the triple integral of the

function φ (x, y, z) in accordance with

the adopted assumptions [1] and locations of a rectangular ground ik-profile section (A ≤l≤J,

J≤b≤D) on the plane xOy, coinciding with the ground of section ABCD of the aspiration chamber.

(1)

(1)

For every ik-ground bounded by the size of lb,

we defined supply of the some straw heap containing different

fractional xj-components. The

value of the specified delivery site is determined by the probability density separation

of the filing of cross-sectional area of the size of the aspiration chamber Q, the coordinate H-section

under consideration, the way the input material K.

![]() (2)

(2)

There is post the straw heap with q1, q2, … ,qj of the j-th component for every ik-ground (i = 1,2,3, ..., j) with BK the

width of the aspiration chamber, that we defined by a probability density separation of the random.

The values of the Q and Bk the width of the

chamber, and the separation of the j-th component in Sk the depth of chamber for each i-th site (i = 1, 2,

3, ..., N) defined by the density

distribution of the probability of filing for a depth of i-th site. Completeness of the passage η of the n-th component of the heterogeneous granular

medium in the purified fraction of the

straw on the mik-th ground depends on the average operating speed of the air flow at the ground.

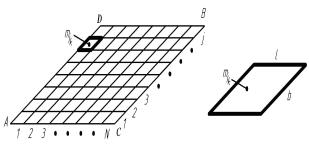

Speed depend on the probability P (V) Jn a

random separation of probabilistic sense, the statistic value for the n-th component in the J-th class of values of variable V , J = 12, 23, ..., (i-1) i, (Fig. 2) and defined by probability

density function Λn(V) characteristic

Vb light components, and supply qin, qi of the n-th and all n-x components mik-th

ground, the laws Rηn (V) complete separation of light n-th

component of the granular medium, depending on their velocities fall velocity, the

probability density (Fig. 2):

Figure.

2. Graphics dependence of the completeness Rηn (V)

passage and release NηnP (V)

passage of the n-th component through mik-th cross section depending on the

height H of the location of the cross section and the

velocities Vn components at a constant average speed of air

flow

The

found regularities and estimates of numerical characteristics of

size quantities of fission sign ik-th component of

the straw heap at the ground of

the aspiration chamber allow to

define new numeric characteristics of the final material

after air separation. These numerical characteristics account

the specific the numerical

characteristics of the numerical velocity fс.в(![]() )i; Мс.в(

)i; Мс.в(![]() )i; σс.в(

)i; σс.в(![]() )i and the

known patterns of functioning aspiration chamber during applying of the straw heap [2].

)i and the

known patterns of functioning aspiration chamber during applying of the straw heap [2].

REFERENCES

1.

Моделирование

процесса фракционирования соломистого вороха в аспирационном пневмоканале с

вероятностными характеристиками распределения соломистого вороха и воздушного

потока. Инженерный Вестник Дона.- №1 -2011. //www.ivdon.ru/magazine/latest/n1y2011/349/]

2.

Московский

М. Н. Интенсификация процесса сепарации семян зерновых в зерноочистительных

агрегатах : дис… канд. техн. наук: 05.20.01 – Технологии и средства механизации

сельского хозяйства / М. Н. Московский ; ДГТУ.- Ростов н/Д, 2005. –с.47-60