Prof. Dr.

Nagiev A.G.

Sumgait state university,Sumgait,

Azerbaijan

E-mail: nashfn@hotbox.ru

ABOUT

AN INCORRECTNESS OF THE USED FORMULA

FOR

RESIDENCE TIME DISTRIBUTION IN CHEMICAL REACTORS OF IDEAL MIXING

In

engineering of chemical processes the formula which expresses function of distribution of

time of stay of particles in the device with a continuous stream is often used. For a long time in engineering of

chemical processes this distribution for reactors of ideal mixture express the

following formula:

![]() . (1)

. (1)

However

the given formula not correctly reflects statistical essence of chaotic process

of wandering of a particle in the device. From this formula the particle which

has entered into the device follows, that, the greatest chance instantly has to

leave it as ýêñïîíåíöèàëüíûì the law defines a maximum of function (1) in the initial moment when ![]() .

.

Obviously,

dominating factor here should be, as well as in the formula (1), average account

time![]() , but

a maximum of this distribution it should be equaled to size

, but

a maximum of this distribution it should be equaled to size![]() ,

instead of

,

instead of ![]() . Here

. Here![]() ;

; ![]() volume;

volume; ![]() îáúåìíûé the substance expense.

îáúåìíûé the substance expense.

This

important argument allows to accept a hypothesis about normal distribution with

a population mean equal on ![]() .

Really, those reasons, which cause premature (concerning size

.

Really, those reasons, which cause premature (concerning size ![]() ) an

exit of a particle from the device, in the statistical relation with the same

intensity can cause its delay in the device (a sign of symmetry of chaos). The

particle which has entered into the device, can instantly leave it or be in it

infinitely long, but, the maximum probability should fall to size of average

account time of stay in the device. Obviously, function does not reflect (1)

this property.

) an

exit of a particle from the device, in the statistical relation with the same

intensity can cause its delay in the device (a sign of symmetry of chaos). The

particle which has entered into the device, can instantly leave it or be in it

infinitely long, but, the maximum probability should fall to size of average

account time of stay in the device. Obviously, function does not reflect (1)

this property.

The

function offered alternatively, has the following appearance:

. (2)

. (2)

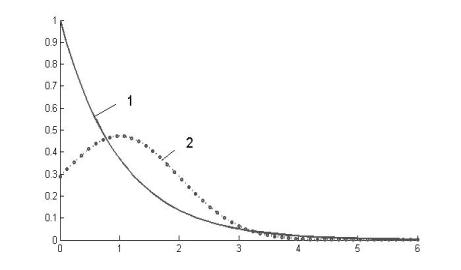

On

fig. 1 schedules of both functions, when ![]() are shown: - standard (1) (a

continuous curve) and offered (2) (dotted).

are shown: - standard (1) (a

continuous curve) and offered (2) (dotted).

Fig. 1. Schedules of standard and offered

functions RTD at ![]() .

.

Apparently,

it is unique, that can pull together these functions, is an identical size of characteristic

time![]() . It

is known, that in the theory of linear systems this parameter is designated as

constant time of a dynamic link.

. It

is known, that in the theory of linear systems this parameter is designated as

constant time of a dynamic link.

In

it the erroneous identification of characteristic parameter (RTD) with size of

constant time of transient of a dynamic link is covered. From it the correct

idea of experimental definition ÔÐÂÏ originates not. It is considered [1,2], that the experimental fact, An

exponential changes of concentration in time after indicator input (a portion

of particles of dye) in flowing system in the form of instantly operating

impulse can be considered as model of probability of time of stay of particles

in flowing system. This position essentially is not true. Introduction of a

portion of the indicator in flowing system will form some concentration of

these particles which decreases eventually. Spending such experience, it is

possible to investigate only the pulse transitive characteristic of a dynamic

link on concentration of the indicator. This experience cannot define - «what

probability of an exit ìå÷åíîé a particle from flowing system in a time interval (![]() ,

, ![]() )?» .

During the initial moment, i.e. at

)?» .

During the initial moment, i.e. at ![]() ,

concentration in a target stream is maximum not because indicator particles

have the maximum probability instantly to leave volume that is why, that the

number of particles of the indicator is maximum in the beginning.

,

concentration in a target stream is maximum not because indicator particles

have the maximum probability instantly to leave volume that is why, that the

number of particles of the indicator is maximum in the beginning.

An exponential the law of change of weight of

the indicator, or its concentration that is the decision of differential

equation ![]() ,

says only that number of particles of the indicator (concentration) in volume

decreases in due course also it finds the exact reflex ion in a target stream

as in system all particles ideally mix up.

,

says only that number of particles of the indicator (concentration) in volume

decreases in due course also it finds the exact reflex ion in a target stream

as in system all particles ideally mix up.

In

work the mathematical conclusion of the correct formula (2) is resulted.

By

the present day the formula (2) is given to attention of experts, having

received publication in 2003 in «the Azerbaijan chemical magazine» [3] which is

reviewed in many bibliographic editions, and in 2005 it is published in Izv.

VUZ - ov «Chimiya i chimicheskaya technoloqiya» [4]. Unfortunately, this

amendment is met by a number of experts sceptically [5] and became a point of

issue on pages of the scientific press. It has entailed the author of the

present report again to come back to a conclusion of the same formula, but with

application of other methodology of the proof.

It is necessary to notice, that the importance of updating of this

formula is indisputable not only for area of processes and devices of chemical

technology, this formula is widely claimed in many areas of engineering

researches - in continuously carried out processes of crystallization,

granulation, crushing of loose materials, etc.

REFERENCES

- O.Levenspiel. Chemical Reaction Engineering, John Wiley & Sons.1999, 3rd ed.

2.

Romankov P.G.,Frolov V.F. Massoobmennie processi chimixeskoy technoloqii./L.,Chimiya,

1990, P.76.

3.

Nagiev A.G. K voprosu opredeleniya funkcii raspredeleniya vremeni

prebivaniya veshestva v reaktore idealnoqo peremeshivaniya// Azerbayjanskiy

chimicheskiy jurnal, 2003, No.2, P.46 –

49.

4.

Nagiev A.G. Kriticeskaya zametka k voprosu opredeleniya funkcii

raspredeleniya vremeni prebivaniya veshestva v apparate idealnoqo

peremeshivaniya.//Izv.VUZ-ov “Chimiya I

chimicheskaya technoloqiya”V.48, 2005, No.11, P.102-104.

5.

Muratov O.V.,Frolov V.F. K voprosu

o raspredelenii vremeni prebivaniya veshestva v apparate neprerivnoqo

deystviya.// Izv.VUZ-ov “Chimiya I

chimicheskaya technoloqiya”V.50,No.11, 2007, 34-39.