Òåõíè÷åñêèå íàóêè/12. Àâòîìàòèçèðîâàííûå ñèñòåìû óïðàâëåíèÿ íà ïðîèçâîäñòâå

Cand.Tech.Sci. Belkin E.A.

Orel State Technical University, Russia

Microrelief geometric

simulation and technical application

Abstract

A

theory for the three dimensional (3D) geometrical model definition of surface

layer microrelief on the basis of a modular geometric principle is developed. A

device design for the active control of a microrelief formation process the

operation principle of which is based on the concept of dynamic holography is also

developed. A microrelief formation technique by specified geometrics is

developed.

1. Theory

One of the

reasons affecting considerably the information completeness of a surface

microrelief analytical description is the application of iteration and

statistical methods in the ground of which there is no a concept of surface

curvature in the local area of the specified point – in the vertex of modulus –

of an osculating paraboloid which is estimated by Riemann – Christopher’s

tensor.

Thus,

the statistical description method of abrasive surfaces with the aid of Markov

chain theory allows building only a two dimensional (2D) model including time

steps of cutting along an idealized line towards cutting. It does not allow

taking into account a cutting edge shape in the direction perpendicular to the

vector of a cutting speed and a cutting edge position with respect to

successive cutting edges that is essential at the explanation of material

removal process.

Thus

and so, the development of mathematical modeling methods allowing the

replenishment of information shortage in a surface microrelief description

occupies a significant place in the shaping theory.

To the

main reason which does not allow building a 3D geometrical model strict enough

and adequate to a real microrelief one refers the application of the parameter totality

of roughness Ra, Rz, Rmax and others in one

dimensional (1D) microrelief models, and parameters ωn, ς, γ0, φ1,

θ1, Θ1 in 2D models.

So far there

are no sufficiently complete and well substantiated 3D geometrical models of

microrelief in the mathematical models of a forming and machined surface. In

such a way, for structuring a 3D geometric model of microrelief one should use

new scientific approaches.

A

modular- geometrical method for a surface microrelief geometric simulation is

developed [1].

The

theoretical justification of a modular-geometrical method for a microrelief

geometric simulation is given. The classification of surfaces with a complex

form from the standpoint of geometry cannot have a scientific justification.

There are no common signs in the structure of surfaces. A complex form surface

is structured on the basis of a modular principle, a structuring method is

defined by the problems of a shaping theory. A modular-geometrical method which

is used for the solution of these problems consists in the approximation of the

local area of a surface with an osculating paraboloid. Riemann – Christoffel’s

tensor is a geometric description for the estimate of a local area curvature.

The analytical assignment of an osculating paraboloid as a geometric image of

the second order of contact with the given local area of a surface is defined

from Tailor series expansion. Tailor series also defines geometric images of a

higher order of contact: cuboloid, quadroloid and so forth. A surface curvature

is estimated in the point of contact through the angle of vector rotation

shifted across itself through a closed loop enclosing the point of contact and

appertaining to its local area, on the osculating surface: on paraboloid,

cuboloid and so forth. The angle of rotation on the surface under consideration

depends on vector coordinates:

![]()

![]()

![]()

where Γχρσ

are the affine connectedness coefficients of the second sort,

indices

ν, μ, τ, ω…= 1, 2;

d1xν,d2xμ - coordinate vector differentials.

This

vector is equal to the difference of two vectors obtained as a result of the

parallel displacement of the vector νχ from the vertex of an infinitesimal

parallelogram into an opposite vertex along its sides compiling various parts

of a closed loop. It follows that the expressions in square brackets are

tensors. Thus,

![]() -

-

Riemann-Christoffel’s

tensor, a considerable component of which is R1212, gives the angle

of vector rotation at the parallel displacement through a closed loop on an

osculating paraboloid limiting the local area of its vertex. The accuracy order

in the definition of covariant differential characterizing changes in vector

coordinates does not allow computing a quadroloid curvature. The geometrical

structure of cuboloid is not studied. In technical applications one should

confine oneself to the approximation of a local area by an osculating paraboloid,

as it is possible to postulate in the following way: a surface curvature in the

point of contact is equal to the curvature of an osculating paraboloid.

The

discrete-defined surface of a work piece in a general case can be approximated

through a module set having a smooth “lacing” each of which represents an

osculating paraboloid of a certain type.

It is

established that a modular approach used for the description of the geometry of

framed discrete-defined surfaces at the work piece abrasion may be accepted as

a basis for surface microrelief structuring.

At the

formation of a simulator describing a surface microrelief one uses a modular

principle for structuring a surface with a complex shape and with the solution

of problems of uneven “lacing” of separate modules.

On

account of the complexity of actually current phenomena the consideration of surface

microrelief formation in a work piece is carried out for an ideal model with

the following assumptions: environment does not affect a 3D geometrical model

of surface microrelief, one can neglect chemical, thermal and dynamic

interactions of a tool and a work piece.

There

is obtained an analytical presentation for an osculating paraboloid through principle

surface curvatures. From equations for the total and mean surface curvature of

an osculating paraboloid:

![]()

![]()

where:

K is Gauss or total surface curvature,

H is the mean surface curvature,

k1, k2 are the principle surface

curvatures,

g11, g12, g22 are the components

of a metric tensor,

R1221 is the essential component of

Riemann-Christoffel’s tensor (curvature tensor).

From

Gauss equation:

R1221

= B11B22,

For the

point of contact of the surface under consideration and of an osculating

paraboloid in the approximation:

g11g22 – g212 = 1;

g11

=g22 = 1;

where a

given point has coordinates X = 0, Y = 0.

The

analytical presentation for the osculating paraboloid:

Z

= ½(k1X2 + k2Y2).

The representation

obtained for the osculating paraboloid through the principle surface curvatures,

is a significant result on the basis of which there was carried out a numerical

computation for the modular geometrical model of surface microrelief.

The

system of criteria is established for the quantitative assessment of

microrelief topography: k1, k2 – the principle surface

curvatures, Rz – the microasperity height. The hypothesis

substantiated theoretically with respect to the information exhaustiveness of a

microrelief topography criterion system is advanced.

The

microrelief geometrical model is a body of modules having uneven “lacing” of

osculating paraboloids. Each osculating paraboloid can be presented as one of

four types pointed out in Tab.1, each type of an osculating paraboloid has a

corresponding orientation with respect to Z-axis

in XYZ- local coordinate system.

Table 1. Types of an

osculating paraboloid

|

Surface type |

Name |

Equation

presented |

Surface kind |

Â11 |

Â22 |

|

I |

Elliptic paraboloid |

|

|

|

|

|

II |

Hyperbolic

Paraboloid |

|

|

|

|

|

III |

Parabolic cylinder |

|

|

|

0 |

|

IV |

Plane |

|

|

0 |

0 |

where ![]() B11,

B22 – the coefficients of the second quadratic form.

B11,

B22 – the coefficients of the second quadratic form.

At the

microrelief surface approximation on experimental data the model accuracy

testing consisted in the estimate of the maximum error δz max at the surface conjugation meant for two

adjacent design points. The value δz

max was defined as a ratio of a maximum jump on Z-axis at the conjugation

of two neighbouring paraboloids to the interval of value changes in experimental

data on Z-axis: Zij max – Zij min . The performed

computations have shown that a surface presentation accuracy depends on the

number of design points falling at the interval of a peak or a trough of

microrelief.

There

is defined a problem for the module factor computation (Tab. 2) of surface

microrelief, in a general case: a surface is decomposed through a chosen pitch

on Z-axis of Cartesian coordinate system by planes parallel to XY-plane and one-parameter family of

surfaces. A subinterval of a family of surfaces is set with respect to a family

parameter. The nodes of microrelief and the families of parallel planes and

surfaces are defined. A module -

surface local area – as a part of the surface of an osculating

paraboloid is rebuilt through five points. The problem solution for a module

factor computation in a particular case for the flat of a part [2] consists in

the following:

Table 2. The module

type definition of the three-dimensional geometrical model (TGM) of microrelief

|

¹ |

TGM module type |

Factor sign |

|

1. |

k1X2+k2Y2≥-2Z; |

k1>0;

k2>0; |

|

2. |

k1X2+k2Y2≤-2Z; |

k1<0;

k2<0; |

|

3. |

k1X2+k2Y2≤

2Z; |

k1>0;

k2<0; (k1<0, k2 >0); |

|

4. |

k2Y2≥-2Z |

k1=0;

k2>0; (k1=0, k2<0); |

|

5. |

Z≤0; |

k1=0;

k2=0. |

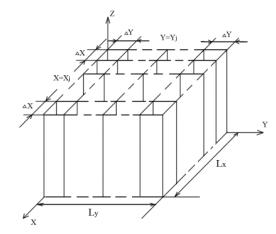

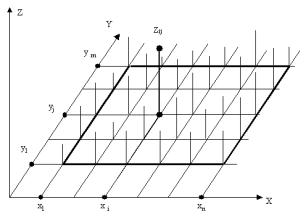

In the

global system of Cartesian rectangular coordinate system there is set a point

field definable with values n on X-axis and values m on Y-axis.

For each point (xi,yj),

![]() ; there is known a value zij (Fig. 1, 2).

; there is known a value zij (Fig. 1, 2).

A subinterval on x-axis is Δx= (xn-x1)/n. A

subinterval on y-axis is Δy= (ym-y1)/m.

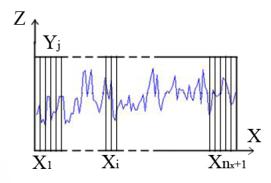

In the

node – (xi+l; yj; zk+1) on the basic area Lx x Ly,

where

1≤i≤nx +1,

1≤ j≤ ny + 1, 1≤ k ≤ (1 + nx)(1 + ny);

![]()

![]()

one defines radii

of curvature Rl1,

Rl2 through

three points in the sections xi+1;

yj; through the nodes of microrelief real

profiles (Fig. 3, 4)

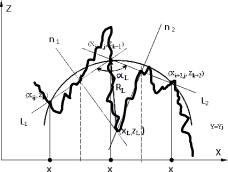

On the basis of

Meunsnier theorem the normal curvatures are calculated in the sections xi+1; yj;:

![]()

![]()

where φ1 and φ2 are the angles between

the principle normal of paraboloid and circular arc normals in the sections xi+1; yj.

Supposing

that a normal curvature in one of the sections is equal to the principle

curvature k1 = kln, through Dupin indicatrix one defines

the principle curvature k2 in the section perpendicular to the

section chosen (Fig. 5, 6).

Fig. 1. The

model of microrelief decomposition Fig.

2 . Basic data for the computation

by interperpendecular planes of microrelief

Fig. 3.

Microrelief decomposition in Fig.

4. The scheme to the computation

the plane y

= yi of

the curvature radius in the section

of

y = yi

Fig. 5. The

XYZ – coordinate system Fig. 6. The modular

geometrical model

in the

point of contact of

surface microrelief 30x6 mcm of a sample

after

flat grinding:(scanning pitch 0.001mcm)

Through

the values k1 and k2 the type of module for a geometrical

model in Cartesian local rectangular coordinate system with the beginning in

the node –(xi+1;

yj) is defined. The

procedures for the numerical computation are developed for the microrelief of

surfaces (flat, circular cylindrical, framed discrete-defined and solids of

irregular form) [3].

2. Inspection tools for control of microrelief

formation process

Modern

inspection tools are designed in such a way that recorders register the values

of parameters from the outline maps of an object. The outline maps are defined

either with low accuracy, or in the course of a rather long period of time. It

is impossible to carry out control of an out-of-the-way object – abrasive

grains moving in work piece material.

There

is one method among the ways for the enhancement of inspection tool capabilities

and the use of information obtained with their assistance for the creation of

three dimensional models, the application of devices investigating an object

holographic display.

The

control principle of tools under consideration is based on the latest researches

of the processes of obtaining an object holographic display in optical and

X-ray (roentgen) bands. The devices in this line allow studying manufacturing

processes not in a plane projection, but in space.

3. Roentgenoprofilograph of active control

The

problem, for the solution of which is used the device offered, consists in the

provision of possibility to carry out control of a microgeometry formation in a

surface layer of a work piece in the course of abrasion and to research the

mechanism of processes accompanying a microrelief formation: chip removal,

abrasive grain spalling and extraction of abrasive grains from the set of

tools, grain microoscillation appearance in the tool set, changes in porous

structure of a tool set, microchip formation, a plastic shift and strengthening

material to be machined with single grain and grain aggregate and so forth.

It is

achieved by that in a roentgenoprofilograph of active control [4] having X-ray

emitter, a crystal resonator for obtaining monochromatic X-ray emission,

focusing crystal systems –collimators, the principle of operation of one of

them is based on eight-beam diffraction, crystal mirrors for the separation and

change of X-ray emission propagation direction, recording environment – crystal

– analyzer for obtaining wave interference, the increase of a three dimensional

interference image is carried out with the aid of a reflecting microscope at

the recording of a holographic display of the object under research, and for

measuring one uses a three dimensional matrix compiled of electron-optical

image intensifiers.

4. Means for microrelief formation

The

procedure for the prediction of new ways of machining is based on the

theoretical researches of a three dimensional geometrical model of a work piece

surface and consists in that a binary correspondence of a forming surface is

established on the basis of the developed allocation for a work piece surface.

Under this correspondence the prediction of new ways of shaping is carried out.

The

work piece surface is represented as a superposition of a three dimensional

geometrical model with module smooth “lacing” which gives the idea of geometry

in whole and a model with module uneven “lacing” which contains the information

of forming surface microrelief .

Types

of machining are defined.

The

first type: ways allowing reproducing forming surface geometry theoretically

correct. In their basis there is a modification of the contact mode of a tool

and a part blank. The way of grinding the blade wing of a gas turbine with the

aid of profilecomposite tools belongs to the first type. [5]

The

second type: ways permitting the representation of work piece surface

microrelief in accordance with given geometrical data. Changes in the procedure

of machining allowance removal are in their basis. The grinding way with the

use of an elbore tool with a metallic fiber set belongs to the second type. [6]

The

third type: ways allowing reproducing the geometry of work piece surface and

its microrelief theoretically correct and in accordance with the given

geometrical data. Tool microgeometry changes in the course of a work piece

machining are in their basis. The way of gas turbine blade wing grinding with a flexible bundle in a magnetic field belongs

to the third type. [7]

For the

realization of the predictable way of microrelief formation allowing producing

its microgeometry according to the given geometrical data the optional

equipment – counterpart (prototype) of a cyclotron – an elementary particle

accelerator is required.

Abrasive

particles existing in a magnetic field are used as a tool. The analytical

assignment of a part surface: a gas turbine blade wing is used for the

computation of the general homohelical path of abrasive particle motion. To the

charged abrasive particles controlled by a magnetic field pertaining to a blade

wing is imparted a motion by a general homohelical path in accordance with the

type of blade, changes of a helical path of abrasive particles and the

substitution of an abrasive particle fraction.

5. Blade wing grinding method for gas turbine by

flexible tool set in magnetic field

The

problems, which the invention is aimed at, consist in combining in one

production cycle the main abrasion operations of a blade wing in a gas turbine

beginning from roughing and up to finishing in one technological system, in

widening the type spectrum of work blades, shaping accuracy increase in

macrogeometry of a blade wing and at the control on the given data: an abrasion

depth, a temperature field and a curvature tensor and so forth, surface layer

microshaping.

The

problems put by should be solved by the offered method of grinding through

which in a resonance accelerator – cyclotron to the charged abrasive particles controlled

by a magnetic field one imparts, relative to a part, a motion along a general

homohelical path on the basis of conditions securing favourable changes in a

general homohelical shaping surface in accordance with a blade type, changes in

the kind of an abrasive particle helical path in accordance with the given

shaping surface, and a possibility of the fraction substitution of abrasive

grains.

In this

connection, before surface machining (entrance and exit edges, back, tray) one

describes gas turbine blades in an analytical way on the basis of the modular

geometrical model of a surface with a complex shape, the obtained analytical

assignment of a blade wing is used for the computation of a general homohelical

path of abrasive particles.

Conclusions:

1.

The method for the definition of microrelief topography is developed

which allows building a three dimensional geometrical model of microrelief on

the basis of experimental data.

2.

A possibility for the substantiation of the prediction of tool

development for passive and active nondestructive control allowing carrying out

estimations on the basis of three dimensional geometrical models is given.

3.

The prognostics in the

development of devices for passive and active nondestructive control of a

microrelief formation process is carried out, the control principle of which is

based on the latest researches of processes in obtaining a holographic image of

objects in optical and roentgen bands.

4.

The substantiation for the possibility of forecasting new machining

methods allowing microrelief forming by given geometric data is presented.

5.

The recommendations for forecasting the method for a microrelief

formation allowing the representation of its microgeometry by given geometric

data, abrasion methods of a blade wing for a gas turbine in a flexible bundle

in a magnetic field are given.

References

[1] Y.S. Stepanov, E.A. Belkin, G.V. Barsukov,

”Simulation of abrasive tool microrelief and part surface”, Monograph, M.:,

Publishing House “Mashinostroyenie-1”, 2004, pp. 215, Patent RF ¹ 2229970,

Method for manufacturing elbore abrasive tool in metal fiber bundle/ Y.S.

Stepanov, E.A. Belkin, G.V. Barsukov, Patent application 29.07.2002, published 10.06.2004, Bulletin ¹

16.

[2] Patent RF ¹ 2187070, “Method for part and

abrasive tool surface microgeometry definition” / Y.S. Stepanov, E.A. Belkin,

G.V. Barsukov, Patent application 27.02.2001, published 10.08.2002, Bulletin ¹

22.

[3] Certificate ¹ 2008612886, Software

“CAD-Grinding”, E.A. Belkin, Patent application 25.12.2007, registered 11.06.2008.

[4] Patent FR ¹ 280204, “Roentgenprofilograph

for active control”/ E.A. Belkin, Patent application 24.10.2005, published

12.02.2007, Bulletin ¹ 22

[5] Patent RF ¹ 2217290, “Method for blade wing

grinding by profilecomposite tools for gas turbine” / Y.S. Stepanov, E.A.

Belkin, G.V. Barsukov, Patent application 26.03.2002, published 27.11.2003, Bulletin

¹ 33

[6] Patent RF ¹ 2229970, “Method for

manufacturing elbore abrasive tool in metal fiber bundle”, / Y.S. Stepanov,

E.A. Belkin, G.V. Barsukov, Patent application 29.07.2002, published

10.06.2004, Bulletin ¹ 16

[7] Patent RF ¹ 2266188, “Method for blade wing

grinding of gas turbine by tools with flexible bundle in magnetic field”, /

E.A. Belkin, Patent application 22.03.2004, published 20.12.2005, Bulletin ¹

35.