Technical Sciences / 8. Metal Treatment in Machine-Building

Boldyrev À.À., Doctor of Technical Sciences, Professor Smolentsev

V.P.

Voronezh State Technical University, Russia

Locating Mechanism of Rheological

Medium Workpieces

with Controllable Physical and

Mechanical Properties

At small series manufacture, broad assortment, and rather short periods

of workpieces manufacture, amount and complexity of designed industrial

equipment, including fastening devices, have great impact on conversion cost of

items. For cutting costs of preproduction it is reasonable to use versatile

accessories and appliances instead of special facilities.

At finishing stages of treatment cutting force declines dramatically,

but more accurate installation of workpieces into operative position is

required. That is why devices for workpieces fastening have to meet moderate

requirements to rigidity and amount of holding force. Besides, power fastening

methods may break the geometrical shape of delicate and thin-walled workpieces

and cause disturbance of setting bases. This causes technical and economical

premises for the use of versatile self-formable accessories with application of

magnetic rheological liquids.

To ensure reliable fastening of workpieces from non-magnetic materials

at treatment on magnetic benches, for example during grinding, we use fastening

method based on rheological properties of ferrofluid [1].

During installation of workpiece on the bench, the fluid flows in front

gap with destroyed structure. The switching on of electromagnetic coils causes

magnetic field with induction ![]() , that directs ferromagnetic particles along force

lines of the magnetic field with formation of chain structure, for destruction

of which it is necessary to apply certain force.

, that directs ferromagnetic particles along force

lines of the magnetic field with formation of chain structure, for destruction

of which it is necessary to apply certain force.

Holding force ![]() of workpiece on the bench of machine-tool is defined

by bonding force, operating in elemental layer of magnetic fluid with area

of workpiece on the bench of machine-tool is defined

by bonding force, operating in elemental layer of magnetic fluid with area ![]() :

:

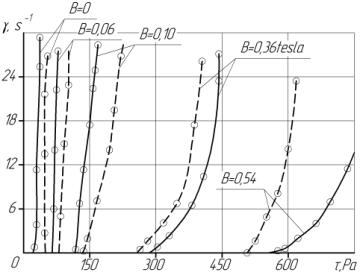

Fig. 1.

Rheological characteristics of magnetic fluid

at

different magnetic induction B and

average diameter of iron particles

dñð=20 nanometers (dashed

lines) è dñð=100 nanometers (full

lines)

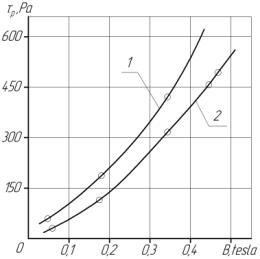

Fig. 2.

Relation of static limit of yield point in magnetic fluid

with

magnetic induction at average diameter of iron particles:

dñð=100 nanometers (curve

1) è dñð=50 nanometers (curve

2)

![]() . (1)

. (1)

Transverse strain ![]() in layer of

ferromagnetic rheological fluid is composed of two components, one of which (

in layer of

ferromagnetic rheological fluid is composed of two components, one of which (![]() ) is conditioned by viscosity forces, the other (

) is conditioned by viscosity forces, the other (![]() ) – by magnetic interaction between particles. It is

deduced from experiments that in static mode the force preventing shift of

workpiece is conditioned by static limit of yield point.

) – by magnetic interaction between particles. It is

deduced from experiments that in static mode the force preventing shift of

workpiece is conditioned by static limit of yield point.

At application of magnetic filed:

![]() , (2)

, (2)

where ![]() – number of

particles in volume unit;

– number of

particles in volume unit;

![]() – particle

magnetic moment;

– particle

magnetic moment;

![]() – distance

between centres of particles.

– distance

between centres of particles.

Or on rearrangement:

![]() , (3)

, (3)

where ![]() – volume of

ferromagnetic particle.

– volume of

ferromagnetic particle.

Intensity of stress ![]() can also be

defined by rheological curve for magnetic fluid of given type (Fig. 1).

can also be

defined by rheological curve for magnetic fluid of given type (Fig. 1).

Yield stress grows with increase of induction of magnetic field

operating in gap, this allows to control physical and mechanical properties of

rheological fluid by change of current on control coil (Fig. 2).

As a result, disclosure of regulation mechanism for parameters of

magnetic rheological fluid allows to work out modes, fixtures and tools and

workpieces processing method in flexible structure manufacture with control of

rheological media parameters.

Cited literature

1. Russian patent ¹ 2312000, ÌÏÊ B23Q 3/15. Method of Fastening of Workpieces from Non-Magnetic

Materials and Device for its Implementation / À.S. Revin, À.V. Lisitsyn, V.P. Smolentsev. 2004136423/02:

alleged 14.12.2004: published 10.12.2007 // Bulletin 34, 2007.

2. Smolentsev V.P. Application of Magnetic Rheological Fluids in Metal

Processing / V.P. Smolentsev, À.À. Boldyrev // Non-Traditional

Methods of Treatment: interacademic collection of scientific papers. Issue. 9. part. 3. Ìoscow: Machine-Building, 2010.

P. 120-129.

3. Magnetic Fluids in Machine-Building / D.V. Orlov, U.Î. Mikhalev, N.Ê. Ìyshkin et al.: under the general

editorship of D.V. Orlov, V.V. Podgorkov. – Ìoscow: Machine-Building. 1993.