Agriculture 4. Technologies of storage and

processing of agricultural products

Doc. Tech. Sc. V. Yu. Ovsyannikov

Voronezh State University of

Engineering Technologies, Russia

Way of

management of a two-level freeze of moisture

The annual increase in

consumption of energy around the world causes the urgent necessity of essential

reduction of power consumption on a unit of production, at creation of power

effective technologies.

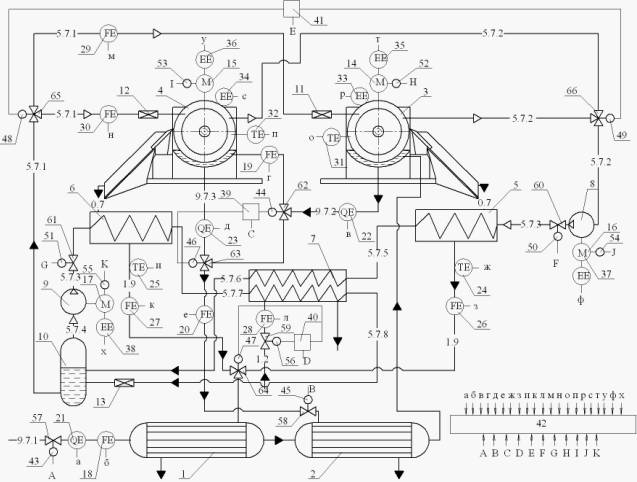

We developed the scheme

of management of two-level process of freeze concentration which provides

repeated use of energy potential of by-products and waste of technological

process (Fig.).

Fig. Scheme of

management two-level freeze moisture

The

scheme contains the two-level freezing installation consisting of the following

elements: the recuperations heat exchanger 1, the recuperations refrigerator 2,

the first 3 and the second 4 drum crystallizers, the first 5 and the second 6

melter, the additional condenser 7, compressors of the first 8 and the second 9

steps of compression of a coolant, an intermediate vessel 10 for a coolant,

temperature-controlled gates 11, 12, 13, adjustable drives 14 and 15 of the

first 3 and the second 4 drum crystallizers respectively, adjustable drives of

compressors of the first 16 and the second 17 steps of compression, the line:

9.7.1 supply of an initial product, 9.7.2 branches of the product concentrated

in the first crystallizer 3, 9.7.3 branches of a product concentrated in the

second crystallizer 4, 0.7 branches of the frozen ice from crystallizers and

its giving in melter 5 and 6 respectively, 1.9 removal of the fresh water which

is forming at melting of frozen ice in the melter 5 and 6, 1.2 water supply in

the additional condenser 7, 5.7.1 of giving of a liquid coolant in vaporizing

space of crystallizers 3 and 4, 5.7.2 removals of vapors of a coolant from

vaporizing space of crystallizers 3 and 4 in the compressor 8, 5.7.3 of supply

of vapors of a coolant in a melter 5 and 6, 5.7.5 giving of a liquid coolant in

the additional condenser 7, 5.7.6 of giving of a liquid coolant in an

intermediate vessel 10, 5.7.3 giving of a vaporous coolant from the compressor

9 in a melter 6, 5.7.4 giving of a vaporous coolant from an intermediate vessel

10 in the compressor 9, 5.7.7 of giving of a liquid coolant from melter 5 and 6

in the additional condenser 7, 5.7.8 of giving of a liquid coolant from the

additional condenser in an intermediate vessel 10, sensors 18, 19, and the 20th

giving of the initial product, the concentrated product leaving the first

crystallizer 3, and a product concentrated in the second crystallizer 4,

respectively, 21, 22, and 23 - sensors of concentration of solids in the

initial product leaving the first crystallizer 3, and a product concentrated in

the second crystallizer 4, respectively, 24, 25 – sensors of temperature of the

fresh water which is taken away from first by 5 and the second 6 melter

respectively, 26, 27 - sensors of a consumption of the fresh water which is

taken away from first by 5 and the second 6 melter respectively and the sensor

28 of a consumption of water, pumped in the additional condenser 7, sensors 29,

30 of an expense of the liquid coolant given in first 3 and second 4th

crystallizers respectively, sensors 31, 32 of temperature of boiling of a

coolant in vaporizing space of the first 3 and the second 4 crystallizers

respectively, sensors 33, 34 of electric resistance of the ice layer frozen

from the first and second crystallizer respectively, sensors 35, 36 of power

consumption of adjustable drives of the first and second crystallizers

respectively, sensors 37, 38 of power consumption of adjustable drives of

compressors of the first and second step of compression of a coolant

respectively, blocks of switching 39-41, the microprocessor 42, executive

mechanisms 43-56, locking gates 57-61, three-running valves 62-66 (à, á, â, ã, ä, å, æ, ç, è, ê, ë, ì, í, î, ï, ð, ñ, ò, ó, ô, õ –

entrance control paths, A, B, C, D, E, F, G – output control paths).

The essence of the offered way is reduced to implementation of process

of concoction at change of temperature and a coolant expense in crystallizers

of installation, an expense, temperature and time of stay of an initial product

in crystallizers, a consumption of cooling water, power of adjustable drives of

compressors of the refrigerator and drives of drums of crystallizers with

impact on the frequency of rotation of a drum and on expenses of the coolant,

cooling water, an initial product and the water received at melting of frozen ice.

Thus an initial product previously give on

cooling to the recuperations heat exchanger washed by fresh water, being formed

when melting the frozen ice, and then to the recuperations refrigerator washed

by the concentrated product, measure an expense and the content of solids in an

initial product on an entrance to the first crystallizer, the current value of

an expense and contents of solids in the concentrated product at the exit from

each crystallizer, time of stay of a product in each crystallizer, and

according to these data correct temperature of boiling of a coolant in an

internal cavity of a drum of a crystallizer and the frequency of its rotation

by change of capacities of adjustable drives of compressors and drives of drums

of crystallizers depending on conductivity of the frozen ice.

Bibliography

list:

Sergey T. Antipov Heat and mass transfer while concentrating liquid media by freeze drying [Text]/ S.T. Antipov, V.Å. Dobromirov, V.Yu. Ovsyannikov; Voronezh state technology academy. Voronezh, 2004. – 208 p.