Ïëàñòìàññû, ïîëèìåðíûå è ñèíòåòè÷åñêèå

ìàòåðèàëû, êàó÷óêè, ðåçèíî-òåõíè÷åñêèå èçäåëèÿ, øèíû

è èõ ïðîèçâîäñòâî

D. Ch. Sc. Abdikarimov

M.N.

Kazakh

National Technical University named after K.I. Satpayev,

Natural humanities institute named after al Mashani, department «Ñhemistry», Å-mail:

mn.abdikarimov@mail.ru

The research of processes of pirolysis

epoxies and siloksan monolithic covers with additions

It’s known about using different

epoxies and siloksan covering as hermetics,

glue and compositional materials in different areas of the technology [1-3].

Certain interest arouses the study of mechanism pirolysis

and working characteristics of compositional materials on base of the epoxy

resin ED-20, polypropylene (PP) and rubbers: epoxies PEF-3A and dimethilsiloxan SKTN-A. As additives the clay has studied.

It contains 8 and 13% of oxides ferric (III). Additives sifted through strainer

with diameter of holes 0,1mm. Mixture of components carefully mixed.

The Initiating system was a dinitril azobys-izoacids (DAÀ) and peroxide of dikumil (PDK). The Compositions on base epoxies polymer

were harden by polyetilenopolyamin (PEPA), siloksan compositions dietilcaprilat

tin-hard K-18.

Thermogravimetric curves sample removed in flow of the inert gas at velocities of the

heating 12,5 °/min,

but thermo mechanic of the study conducted on sample by diameter 6 0,1 mm and thickness 2 we on air at load 10

kg/mm2. Struñturå polymeric

composition studied on electronic microscope EVM-100-LM on method of the carbon

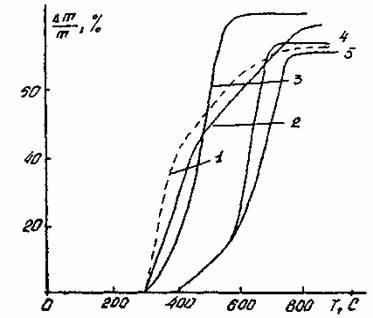

remarks. Thermogravimethric ñurves

different sample is presented on figure 1. As it is seen, the temperature begin

decompositions polymeric composition on base of the epoxy ED-20 and epoxies

rubber PEF-3A begins under 305 °Ñ.

The Additives of the clay and rubber mite do not influence upon mechanism pyrolysis epoxies composition, peroxide dikumil

promotes the offset of the move of the crooked temperature in area on 50-70 Ñ

at the average. The Losses of the mass sample under 400 °Ñ 16-40 % forms for

different composition 73-78 % reach under 800 °Ñ, but compositions, containing mainly epoxies rubber PEF-3A with

accompaniment ED-20, have a loss of the mass 85-88 %.

Thermogravimetric curves were

taken of on constructed plant in rare gas stream with 12.5 º/min speed of

heating.

Thermogravimetric curves of

SKN-40 decomposition with different additions are represented on 1st and 2d

figures

The Temperature begin decompositions

of silks composition, including epoxies rubber PEF-3A; harder and sand, forms

390 °Ñ, under 600 °Ñ loss of the mass sample

is 19-22 %, under 800 Ñ - 71-76 %.

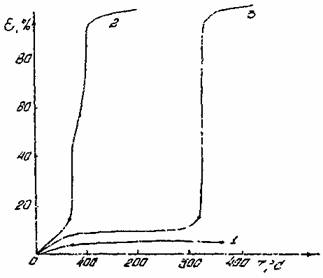

On figure 2 brought results thermomechanic test epoxies composition. From drawing

follows that sticky resilient characteristic of epoxies polymer increase with

introduction to composition of polypropylene (the curve 2), conditioning growth

characteristic high elastic under additional contents rubber (the curve 3).

High resilience to epoxies composition

3 reveals itself before the temperature 330 °Ñ, when sample begins the flow. Probably, polypropylen

and peroxide of decimal interact with epoxygroops of

the resin and rubber and form sew net.

The

figure 1. Thermogravimetric

curves sample: Vwarm = 12,5 °/mines in flow of the

argon, V – velocity.

Cipher Composition (Weigh station part):

1. 18 Epoxy ED-20 100

PEPA

10

The Clay 1 (13 % - Fe2Î3) 20

The Peroxide 2

2. 19 Epoxy ED-20 100

Clay

2 (8 % - Fe2Î3) 20

The

Rubber mite 20

PEPA

10 .

3. 29 Epoxy ED-20 25

PEF-3A

100

PEPA

2,5

The

Rubber mite 40,7

4

51 SKTN--À 100

K-18

10

PEF-3A

10

5

52 SKTN--À 100

K-18

10

PEF-3A

10

Sand

20

The

figure 2. Thermomechanical

curves sample epoxy with additive:

Cipher Composition (Weigh

station part). ε – deformation.

1

18 Epoxy

ED-20 100

PEPA

10

The

Clay 1(13 % Fe2Î3) 20

The

Peroxide dikumil 2

2.

23 Epoxy

ED-20 100

Dinitrilazobisizooil acid 2

The

Rubber mite 10

Polypropylene

20

PEPA

10

3

25 Epoxy

ED-20 100

PEF-3A

10

The

Clay 2 (8 % Fe2Î3) 4

Polypropylene

10

PEPA

10

Electronic-microscopic studies is

installed appearance in the area of crystalloid of epoxide

composition, having originally amorphous phase at accompaniment of the clay, ïîëèïðîïèëåíà and PEF-3A, and formation completely çàêðèñòàëëèçîâàííûõ structures at introduction to epoxies composition of the clay and PDK.

It Is Shown that diameter of the times syloksan

composition, having in composition rubber PEF-3A and harder K-I8, is changed

within- 22500-45000 Jc. The Accompaniment of sand

promotes the reduction a diameter times within 13000-22500 But.

On the grounds of called on studies

possible to do the following findings:

1. The Peroxide of dikumil displaces the move crooked in area of the low

temperature on 50-70 Ñ.

2. The Additives polypropylene and

epoxies rubber promote increase an sticky elastic characteristic to epoxies

composition in broad interval of the temperature.

3. Sand conditions the reduction of

the diameter of the times syloksan composition.

LITERATURE:

1. Fedukin

D.L, Mahlin F.A

Techno- and technical properties of rubbers. M., Chemistry, 1985/240 p.

2. Radchenko

I.I. The Encyclopedia of polymers M.: Counsil Encyclopedia,1972/T.I. - P. 310-322.

3. Dogadkin

B.A., Doncov A.A., Shershnev

V.A The chemistry of elastomers. M.: Chemistry, 1981,

376 p.