EXPERT SOFTWARE FOR

IMPROVING NONCONVENTIONAL PROCESSING PARAMETERS

Tiberiu Mariu KARNYANSZKY

Dan

Laurenţiu LACRĂMĂ

Faculty

of Computers and Applied Computer Science

“Tibiscus”

University

of Timisoara , Romania

ABSTRACT

This paper is focused on the improving of the nonconventional

processing parameters using computers and expert software. All over the world

the nonconventional processing is used in cases where traditional techniques is

too complex or too expensive, because the steel is very hard. In such situations

non conventional methods like electro erosion, electrochemical erosion, complex

electrochemical erosion and laser erosion could be the solution.

KEYWORDS

complex electrochemical erosion, neural networks

1. THEORETICAL CONSIDERATIONS

In order to develop a

program that automatically performs the functions’ settling of the dependence

of the technological parameters on the influencing factors, we have considered

the following mathematical patterns with polynomial functions. Concretely, let

us consider the dependences as being of one (1, 2, 3) and

two variables (4, 5) only, namely:

(1) z = a0 +a1

· x

(2) z = a0 +a1

· x + a2 ∙ x2

(3) z = a0 +a1

· x + a2 ∙ x2 + a3 ∙ x3

(4) z = a0 +a1

· x + a2 ∙ y

(5) z = a0 +a1 ∙ x +a2 ∙

y +a3 ∙ x2 +a4 ∙ y2 +a5

∙ x ∙ y

the establishing of the

coefficients a0, a1, …being based on the smallest squares

method ([1]).

2. OBTAINING THE PATTERN USING MATHEMATICAL METHODS

We have obtained the following mathematical patterns of the dependence

of the EEC processing productivity (Qp) on the current density (j) and

on the relative speed between PO and TO (vr), at the debiting of the

metallic carbures using OT of OL ([2]):

·

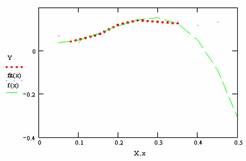

P10 debiting (figure 1, only

the dependency between Qp and j with vr=6):

Qp

= 0,06145 -0,9006∙j +9,55098∙j2 -18,45541∙j3, error 4%

·

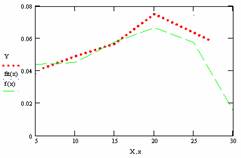

P10 debiting (figure 2, only

the dependency between Qp and vr with j=0.08):

Qp

= -0,06929 -0,00872∙vr +0,00083∙vr2 -0,00002∙vr3, error 5%

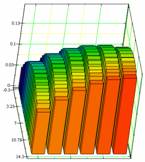

·

P10 debiting (figure 3):

Qp

= -0,1376 +1,3513∙j +0,0136∙vr -2,155∙j2 -0,0004∙vr2 -0,0055∙j∙vr, error 16,58%

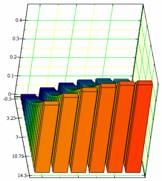

·

P20 debiting (figure 4):

Qp

= -0,0674 +1,2659∙j +0,0058∙vr -2,6495∙j2 -0,0002∙vr2 +0,0130∙j∙vr, error 9,33%

·

P30 debiting (figure 5):

Qp

= -0,1168 +0,6536∙j +0,0133∙vr +1,2880∙j2 -0,0003∙vr2 +0,005∙j∙vr, error 22.21%

·

P40 debiting (figure 6):

Qp

= -0,0303 +0,2857∙j +0,0092∙vr +0,24∙j2 -0,0003∙vr2 +0,032∙j∙vr, error 12.42%

Table 1. Experimental results –

P10 debiting

|

j |

vr |

Qp |

|

j |

vr |

Qp |

|

0.08 |

6 |

0.0418 |

|

0.25 |

6 |

0.1416 |

|

|

10 |

0.0491 |

|

|

10 |

0.1573 |

|

|

15 |

0.0567 |

|

|

15 |

0.1805 |

|

|

20 |

0.0752 |

|

|

20 |

0.2063 |

|

|

27 |

0.0592 |

|

|

27 |

0.1069 |

|

0.15 |

6 |

0.0750 |

|

0.35 |

6 |

0.1253 |

|

|

10 |

0.0930 |

|

|

10 |

0.1312 |

|

|

15 |

0.1125 |

|

|

15 |

0.1632 |

|

|

20 |

0.1357 |

|

|

20 |

0.1753 |

|

|

27 |

0.0994 |

|

|

27 |

0.1156 |

|

0.20 |

6 |

0.1219 |

|

|

|

|

|

|

10 |

0.1132 |

|

|

|

|

|

|

15 |

0.1212 |

|

|

|

|

|

|

20 |

0.1712 |

|

|

|

|

|

|

27 |

0.1011 |

|

|

|

|

|

|

|

|

Figure 1. P10 debiting, Qp dependency on j

(where Y are the experimental results, f(x) is the best approximation) |

Figure 2. P10 debiting, Qp dependency on vr

(Y are the experimental results, f(x) is the best approximation) |

By

analyzing the determined functions there can be observed that:

·

the Qp dependence on j

(only) using the 3 rank functions is correct with an maximum 4% error;

·

the Qp dependence on vr

(only) using the 3 rank functions is correct with an maximum 5% error;

·

the Qp dependence on j and

rs (relative speed) using the 2 rank functions is correct with an

maximum 22% error;

·

Qp can be expressed both

depending on j and rs;

·

Qp depends more on j than

on rs, both due to the 1 rank component and to the 2 rank one;

·

j

can be used to control Qp better than rs.

|

|

|

|

Figure 3. P10 debiting |

Figure 4. P20 debiting |

|

|

|

|

Figure 5. P30 debiting |

Figure 6. P30 debiting |

3. OBTAINING THE PATTERN USING NEURAL NETWORKS

In order to

solve the above-mentioned task, the authors of this paper selected the

Multilayer Perceptron trained with the error back propagation rule. As stated

in the scientific literature MLP is a simple and powerful tool that can be

applied successfully to solve many problems.

The Universal

approximation theorem formulated by Cybenko proved rigorously that a single

hidden layer MLP is sufficient to uniformly approximate any continuous function

with support in a unit hypercube. Thus, a single hidden layer neural net should

be good enough to obtain a satisfactory solution to the CEE parameters

correlation problem.

Nevertheless

the Universal approximation theorem has a limited practical value. The neurons

inside the unique hidden layer tend to interact with each other globally.

Therefore in complex situations this interaction makes it difficult to improve

the approximation at a certain point without worsening it at some others. In

practice, two or more hidden layers can prove useful in order to make the

approximation process into a more manageable one.

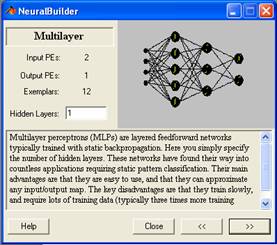

Figure 7. Neural Builder GUI

window, Neuro Solutions 4.31

Consequently

the authors decided to experiment and compare the results of three alternative

neural architectures:

a. Single

hidden layer MLP;

b. Two hidden

layers MLP;

c. Three

hidden layers MLP.

All the three

neural nets were implemented using the Neuro Solutions 4.31 software from Neuro

Dimensions Inc. This integrated environment provided us the possibility to

quickly build, train and test the networks using a simple and efficient set of

GUI and results windows as shown in Figure 2.1. Each of the three neural nets

architecture is depicted in Figure 2.2 as shown in the Neuro Solutions user

screen.

As stated

before each of the three neural nets is able to assure a reasonably good

approximation of the curve tp=f(I,WTO), but the authors

tried to find out which of them is the best solution both in terms of precision

and efficiency.

|

|

|||||

|

Input layer |

Hidden layer |

Output layer |

The criterion |

||

|

a. |

|||||

|

|

|||||

|

Input layer |

Two hidden layers |

Output layer |

The criterion |

||

|

b. |

|||||

|

|

|||||

|

Input layer |

Three hidden layers |

Output layer |

The criterion |

||

|

c. |

|||||

Figure 8. Neuro nets architecture

3. Experimental Results

Using the

three structures represented above the authors performed the experiments with

the same training set containing 388 data samples.

|

|

Single hidden layer MLP: CV Avg. Cost @ 0.05 Training epochs @ 760 |

|

|

|

|

|

Two hidden layers MLP: CV Avg. Cost @ 0.02 Training epochs @ 580 |

|

|

|

|

|

Three hidden layers MLP: CV Avg. Cost @ 0.02 Training epochs @ 670 |

|

|

|

Figure 9. CV and T Average Costs

Each sample

consists of the directly measured technological parameters of the debiting

process on a real CEE machine tool (i.e. tp, I and WTO).

All data were collected from the same equipment using only OL37 stainless steel

samples. The data collecting procedure was made in accordance with the rules stated

in [4].

The CV and T

average costs together with the number of minimum necessary training epochs are

shown for all the three neural nets in Figure 3.1.

The test set

was the same for all the three nets and it was performed with 82 different data

samples.

Table 2. experimental results with Neural

Networks

|

Neural net Structure |

Incorrect estimations |

|

|

Samples |

[%] |

|

|

One hidden layer |

5 |

93.902 |

|

Two hidden layer |

3 |

96,342 |

|

Three hidden layer |

2 |

97.561 |

4. Conclusions

The most important

concluding comment of the above results is that the use of neural nets produces

a significant improvement from the method of curve fitting with the third rank

polynomial functions. This progress was achieved without employing great

programming effort or extensive time-consuming computations.

Analyzing the incorrect

estimations in all the three cases some concluding remarks are

obvious:

·

The two hidden layers MLP is the best solution because it

gives more precise results than the single hidden layer structure;

·

The three hidden layers structure performs a little better at

the testing stage, but the improvement is not significant and consequently the

added costs are not worthwhile;

·

Better results should be obtained with an enlarged number of

data samples in the training set, but the data collection procedure involves a

great effort and it is time consuming.

Further improvements in

performance could result from using a more flexible structure as RBF neural

nets. This could lead to the development of a neural network able to solve the

parameters control for a set of similar but different stainless steel qualities.

The use of neural networks

to manage mechanical processes parameters is a very useful practice, but

finding the optimal solution is not straightforward and need a carefully work

from the data collection stage to the final implementation, training and testing.

REFERENCES

[2] Tiberiu-Marius Karnyanszky, Contribuţii la conducerea automată a prelucrării dimensionale prin

eroziune electrică complexă, Teză de doctorat,

Universitatea “Politehnica”

[2] Ştefan Kilyeni, Metode numerice, volumul I+II, Editura

Orizonturi Universitare,

[3] Zenoviu

Lăncrăngean, Contribuţii

la prelucrarea corpurilor de revoluţie prin eroziune electrică

complexă, Teză de doctorat, Institutul Politehnic „Traian Vuia”

1 Assoc.Prof. Tiberiu

Marius KARNYANSZKY, PhD., Dipl.Eng.,

“Tibiscus”

+40/744/599190

1 Assoc.Prof. Dan

Laurenţiu LACRĂMĂ, PhD., Dipl.Eng.,

“Tibiscus”

+40/722/329912