Технические науки/1.Металлургия

Bogomolov A.V., Kanayev A.T.

Pavlodar

State University named after S. Toraigyrov, Kazakhstan

Kaken A.S.

Innovative University of

Eurasia, Kazakhstan

INFLUENCE OF SILICIUM ON OPERATIONAL

PROPERTIES OF ACCESSORIZED STEEL.

In determining

of a chemical composition of a material for mass production of thermally

strengthened fittings from rolling heating plays a role of an effective

alloying and a micro alloying. The widest distribution has received silicium because of relative

availability and low cost in metallurgy which is entered into steel as a

deoxidant and the alloying element.

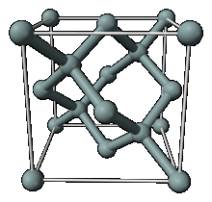

Cubic

face-centered diamond-type crystal lattice of silicium - (figure 1).

Figure 1 - Crystal

lattice of metal silicium

Silicium

besides ability to oxidize steel actively, due to the ease of transfer of its

valence electrons from an external cover 5s23p2 to the atoms of oxygen having

an external electronic cover 2s22p with achievement of steady electronic

configurations 2s22p6 as a result of it. There is an available very useful

property for alloys hardening: ability to raise firmness of martensite against tempering.

Silicium

makes difficult and ambiguous impact on toughness, plasticity and impact

strength of iron and steel. This influence changes depending on the content of

the silicium, other alloying elements in steel and nature of its thermal

processing.

The

majority of researchers [1] express unanimous opinion that silicium at its

contents to 1,5 — 2 %, as well as manganese, makes strengthening effect on iron

and steel, practically without worsening thus plasticity. However, the estimate

of influence of silicium on impact

strength and resilience to fragile destruction of iron also became considerably

more contradictory. A.P.Guljaev has showed

that in pure (0,002 % C) iron of vacuum

smelting adding 1 % of Si is essentially reduce Tcr and only during

further increasing of its concentration in an alloy, It is observed the increasing of the temperature,

though at 2 % of Si iron appears even less inclined to fragility, than in its

absence. This positive effect is connected with oxidize effect of silicium in

steel.

M. P. Brown considers that silicium,

especially in a complex with manganese and lame, provides significant

reinforcement while saving high plasticity and viscosity if the content of

carbon isn't higher than 0,25 %. while working

with steel 0,35% С, in the tempered and high-released condition it was found

out that unlike manganese, when we increase the content of silicium to 2,5 % plasticity

continuously improves. The presence of silicium in high-thermo strengthened

steels is obligatory, in connection with its beneficial effect on sub-structure

of martensite. There is data that silicium (under 2%) reduces a tetragonality

of initial martensite lattice and reduces tendency to formation of hardening

cracks as reduces a sample deformation during hardening.

At

the same time, there are also other estimates of influence of silicium on

properties of iron and steel. So, increase of the content of silicium up to 0,6

% doesn't influence on impact strength of technical (0,05 % C) cast iron, but at further growth its concentration it

sharply decreases L.I.Gladstein and

D.A.Litvinenko have noted the increase Tcr in the normalized

construction steel from 1,46 % of Si. It is specified (K.Taffner, K.Meyer) that

at the contents over 0,5 % silicium makes negative impact on Tcr of

hot-rolled construction steel, and at the contents over 0,37 % silicium makes

an adverse impact on work of distribution of cracks in normalized and improved

steels with 0,15 — 0,20 % of C.

Provided analysis of the researches results

from various authors testifies that influence of silicium on a ratio of

durability, plasticity and tendency of iron and steel to fragile destruction is

ambiguous. It is in a difficult dependence on the content of carbon, other

elements in steel, technology of its production and thermal processing. Therefore

according to data it is not possible to choose the optimum maintenance of these

elements.

Systematic

researches were required[2] in this

field, especially when we know the specificity of the final product —

high-strength fixture steel of periodic profile which has active-operating

concentrators of tension (system of cross-section and longitudinal edges of

rigidity) and testing difficult influence of external and internal forces

during a work in preintense beton.

As

a result of the carried-out laboratory researches of fixture steel of 35 GS at

increase in the content of silicium up to 1,5 % on weight strength goes up to

100-140 MPas, a fluidity limit goes up to 50-120 MPas, relative lengthening

reduces to 2,4-2,9%.

Dependence

of the strong properties and plasticity of fixture steel from nuclear

concentration of silicium is expressed by the following equations of regression:

sТ=334+38Si

sв=509+41Si

d5=36-1,5Si

With the

growth of the content of silicium from 0,21 % to 1,5 % with weight (0,43-3 %

ат.) the ratio of sТ\sв changes

slightly and is in limits 0,66 - 0,70.

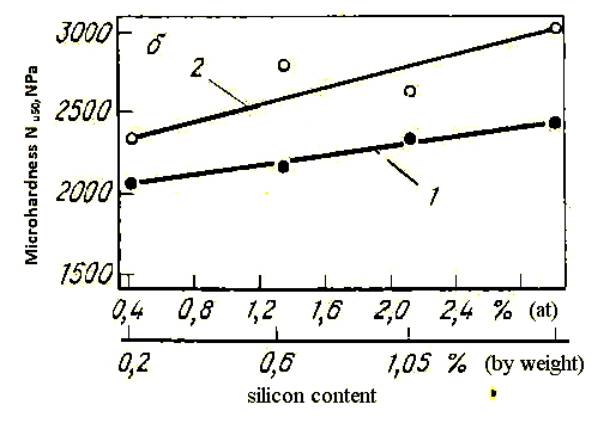

Figure 2 - Influence

of silicium on the microhardness of ferrite and pearlite

On

the figure 2 there is data on influence of silicium on microhardness of ferrite

and a pearlite hot-rolled fixture steel; each point — on average from 200

measurements. If we express, concentration of these elements in nuclear percent

that is the most reasonable from physics point of view.

This

article was prepared within the program

of basic and applied researches of the Ministry of Education and Science of the Republic of Kazakhstan on a subject from 1796\GF

«Development of technology of the integrated production of high-strength

fixture hire from continuously cast

preparations» (Doctor of Technical Sciences, Professor A.T. Kanayev).

References:

1.

High-strength fixture steel. Kugushkin A.A., Uzlov I.G., etc.- Moscow: Metallurgy,

1986, 272s.

2.Kanayev A.T., A.V. Bogomolov, E.N.

Reshotkina T The research of defects and thermal

hardening of fixture rolling from the continuously cast preparations / / Steel,

№ 6, 2010 - Moscow, p. 87-91.