УДК 63.86.054.2

Технические науки/3. Отраслевое

машиностроение

A post-graduate, Basheva E.P., Ph. D. Alexeev G.V., Ph. D. Dmitrenko

N.A.

Санкт-Петербургский национальный исследовательский

университет информационных технологий, механики и оптики Институт холода и

биотехнологий

Problem capping

device with twisted flow phases

"Smoothie"

drink is currently widespread in the field of healthy food. Its technology

includes freshly processed fruit and vegetables. Its purpose is to quench

thirst, improve body tone, increase appetite. This beverage category is a

medium carbonated refreshing lemon drink with pulp.

Some

manufacturers try to combine smoothie making with carbonation. In this case,

while designing the machine for the beverage making one has to solve some

problems related to the specific behavior of gas-liquid suspension, which is

connected with certain difficulties in the design of the technological device.

In particular, it is related to the output of the finished product from the

process vessel, where the grinding of raw materials takes place.

To

solve this problem means both to develop and experimentally test the model of

three-phase fluid leakage to the fixed barrier. It requires:

•

The study of the flow of carbonated lemon drink when leaving the apparatus and

filling containers.

•

The study of possibilities of containers packaging with finished product

(analytical modeling with variable flow regimes)

•

The development of components for sealing containers with lemon carbonated

drink (choice of concept scheme and power operative drive)

Complex

three-dimensional fluid flow, which takes place in an device with a stirrer,

arises as a consequence of the rotational movement of the agitator. Obviously,

the tangential flow, which is formed when using mixers, is a primary one.

In

an experiment carried out the study. On the basis of numerical experiments on

the model described above a graphical

dependence of the energy the jet liquid discharge on such parameters as nozzle

diameter, velocity, and temperature was received. To confirm these data

one experiments on the device were

conducted.

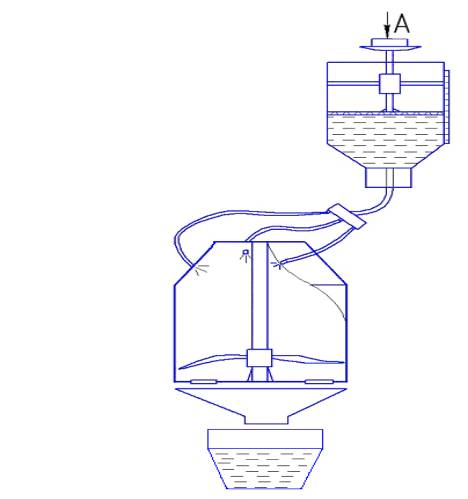

Fig. 1 Schematic diagram the experimental apparatus

In

an experiment carried out the following studies.

•

Changing F, changing the pressure P, the velocity of the ω, the expiration

time t, consumption Q

•

After installing the blades - Flowing pressure sensors measure the pressure

force f on the plane blades

•

Comparison with the calculated by the model adopted in the model. To varying

degrees of carbonation μ

•

Plotted F = f (F, ω, Q, μ)

•

Compare the theoretical part of the practical.

Preliminary

results give reason to speak of a fundamental confirmation generated model,

although more accurate conclusions can be made on the basis of more extensive

and accurate experiments.

References:

1.

PG Romankiv, MI Kurochkin's "Hydro chemical processes."

Leningrad.-1982.-150 p.

2.

DG Pazhi, VS Galustov "atomizer".-M.: Chemistry, 1979.-216 p.

3.

Genick Bar-Meir, Ph. D. «Basics of Fluid Mechanics». Chicago.-2011.-452 p.