B.B. Orazbayev- Doctor of Engineering Science, K.N.

Orazbayeva- Doctor

of Engineering Science, B.E. Utenova- PhD, L.T.- Kurmangaziyeva –PhD.

Atyrau Institute of Oil and Gas

Information systems for optimisation and control of sulphur production units

Abstract:

This paper

develops the

structure for

and creates

the basic

functional blocks

for information systems

for the

optimisation and

control of working regimes

for basic

technical system

for sulphur

production

units. The suggested information system

includes complex

modelling algorithms for

interdependent technological systems

and a set

of algorithms for

solving multi-criteria optimisation and

control problems in a fuzzy

environment, as well as an intelligent interface and

using standards of CALS

technology. The

basic results

of the

programme

to implement the model which

has been

worked out

and the

given description of the basic

interface of the information system

for optimisation and

control of working regimes

for sulphur

production units

and sub-system modelling processes for

sulphur production are given.

Key words: information system,

sulphur production units,

interface, sub-system modelling, multi-criteria optimisation, decision maker,

fuzzy data.

I. Introduction

In industrial situations, the

decision maker

(the head

of the

technical installation, process

engineer, operator) frequently finds

him or herself in a situation where

in order

to optimise the

decision, it is necessary to process a large volume

of information, consider a set of alternatives, take

into account

the impact

of various

factors, evaluate the

implications of one or other decision on conditions of uncertainty. The

situation arises,

when it becomes necessary to resolve production problems in the control

of multi-criteria installations, since

oil refining processes are

such, including sulphur

production units

in oil

and gas

refineries.

In order

to resolve

such problems, computer information systems

for optimisation and

control (CISOC)

are always

beneficial, based

on modelling which

allow, in the advice

regime, the

taking of optimal decisions for

management of the installation, and

the processes inherent in the same.

Such systems

bring together modelling methods, optimisation, decision making

and the

possibilities afforded by modern computer equipment, allowing for

significant improvement in a speeding up of the

optimisation and

control process

[1].

II.Problem setting

The aim

of this

research paper is the development of structures and

the formation of basic functional blocks

for information systems

for the

optimisation and

control of working regimes

for technical systems

for sulphur

production units. In order

to increase the

effectiveness of the contents of computer information systems

for optimisation and

control (CISOC), we suggest the

inclusion of the following basic

blocks: a system of algorithms for

decision making

in optimisation and

control tasks,

a modelling system,

a data

and knowledge base,

model identifiers and

a user interface. These

blocks link

the information streams, and

each of them fulfils

its own

function. [2, 3]

The peculiarities of most industrial installations, including sulphur

production units

lie in the fuzziness of their input

data. In such cases,

it becomes

necessary to formulate the

knowledge and

opinion of the person

making the

decisions (the

decision maker),

specialists and

experts

which is characterised by fuzziness and

qualitative in nature. In order

to solve

fuzzy optimisation tasks

such as these, leading

to the

optimal decisions, it is necessary to include in the computer information systems

for optimisation and

control (CISCOC), elements of artificial intelligence allowing interaction in real or professional languages. This

can be made possible by artificial intelligence methods

[4], that

is by including logical

conclusion and

results clarification blocks,

multi-criteria fuzzy

optimisation and

control algorithms in the knowledge base

of the

computer system and also

by having an intelligent interface

[5]

III. Results

The results

of the

research which

has been

carried out,

suggest the

following steps

for the

formation of a computer information system

for optimisation and

control (CISOC):

1. The identification of problem areas,

and the

task to be solved,

contained in the arrangement of the optimisation and

control problem.

2. Formalising of the knowledge of the decision maker,

specialists and

experts of the installation and

task at hand.

3. Formation of a knowledge and

data base.

4. Development of a system

of models

for the

installation.

5.

Arrangement of the

optimisation and

control problems, and

development of algorithms for

their solution.

6. Development of an

intelligent user interface.

7.

An implementation programme for

the models

and algorithms which

have been

developed.

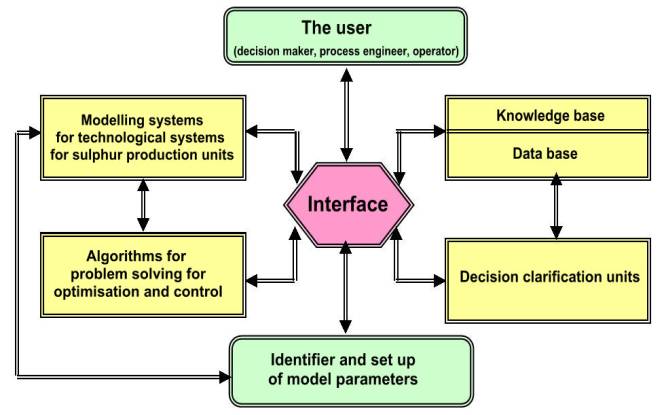

We are

suggesting the

following structure for

information systems

for optimisation and

control for

sulphur production units

based on mathematical models

of the

installation (figure

1).

Let us consider the

functionality of the basic

blocks of the computer information system

for optimisation and

control. (CISOC)

The user – decision maker (in

our situation the

operator or process engineer) selects

a working

regime for

the installation, providing for

the optimal

value of local criteria, such

as economic, ecological and

technological characteristics. The

solution is selected depending on the complexity of the industrial situation, for

example on the product

issue plan,

the composition of the incoming sulphur, production quality

requirements, ecological safety

etc. taking

into account

the relative importance of local criteria and

set limits

(for the

value of control and

regime parameters or local criteria).

Figure 1 – Structure of Computer Information System for Optimisation and Control (CISOC)

In order

to solve

this problem, the

decision maker

uses a set of models for

technological systems

for sulphur

production units, algorithms for

solving multi-criteria optimisation and

control problems taking

into account

fuzzy input

data, and,

if necessary knowledge and

data bases,

decision clarification blocks

etc. In the configuration and

adaptation of systems to new working

conditions, the

decision maker,

specialist or expert may

fulfil the

role of expert in order to fill the

knowledge base

and implement the

collection and

processing of qualitative indicators

[6].

The block

set of models for

the optimisation and

control of the system

installation contains various

models, including fuzzy

models of each separate element

of the

industrial system,

joined together into

one system,

allowing for

the system

modelling work

of the

installation to be carried

out as a whole.

The function of these models

is to determine (estimate) the

value of local criteria relative to the value

of input

activity.

The set of algorithms for solving the optimisation and control problems, for

example, the

algorithms which

have been

put forward

in research papers

[7,8], the combination of these, and

others are

intended for

the solution of multi-criteria optimisation and

decision making

problems for

the selection of optimal control regimes, including those

in a fuzzy environment. These

algorithms, based

on complex

models, knowledge bases

and decision clarification blocks,

implement the

search for

rational working

regimes for the

installation according to the criteria which

have been

selected and

determine the

recommended values

for the

control activities required to provide for

these working

regimes. The

right to make the

final selection lies,

as a rule, with

the decision maker.

The function of the knowledge and data bases is to store

the formalised knowledge of specialists and

experts, researchers in the said

sphere and

statistical data

concerning production. Information from

these blocks

is used

in the

process of analysing the

basic indicators of the installation and

decision making

for the

drawing up of industrial reports

and the

adaptation of models to new conditions.

The function of the interface is to provide

for a convenient interactive working

regime between

the user

and the

system in control of the installation, and

also in the implementation of a range

of other

functions of the computer information system

for optimisation and

control (CISOC). In the process

of working

with the

system, if necessary the

following are

implemented: output

on the

display of a diagram

of the

industrial installation and

information concerning the

ecological condition of the installation, showing

on the

the screen

the value

of control

parameters and

the results

obtained in the form

of visual

observations of the process

of optimisation of working regimes

of the

installation, input

and correction of the parameters necessary for

optimisation and

the provision of ecological safety

of the

production in a form

convenient for

the user.

The decision clarification blocks implements the

prompting strategy and

clarification of the results

obtained. Clarification of the results

obtained, in a form

which is compact and

convenient for

human analysis, is carried out

by way

of the

fixing of all the

considerations received by the system

in the

event of alternative selections.

In order

to adjust

and adapt

models of technological installations to new working

conditions and

identifier of model parameters is added to the contents of the computer optimisation system.

This block

is in fact a programme which

carries out

the checking of the models

for adequateness, and,

if necessary, allows

for recalculation (identification) of the model

parameters.

The effectiveness of such intelligent computer systems

for the

control of various types

of production is determined by the quality

of the

formalisation and

presentation of knowledge, the

models and

algorithms which

have been

developed for

solving control

problems as well as the user

friendliness of the user

interface.

Thus, in order to increase the

effectiveness of the computer information system

for optimisation and

control (CISOC), a set of algorithms for

modelling inter-related technological systems

and multi-criterial optimisation and

control regimes

for installations based

on CALS

technology, developed in a fuzzy

environment with

an intelligent interface must

be included.

According to the results

of analysis and

comparison of selection criteria, in this

paper we have chosen

to use

Visual Basic

for the

programme to implement the

models which

have been

developed in the field

of sulphur

production. This

brings us to a description of the interface for

the information system

under development. The

main menu

is shown

in figure

2.

As can

be seen

from the

menu shown,

the suggested information system

for optimisation and

control is made up of three

blocks (sub-systems): the

modelling system,

the optimisation system

and the

control system.

In this

paper, the

programme for

implementation of the modelling systems

developed for

processes in the production of sulphur based

on mathematical models

of basic

sulphur production units

for sulphur

production equipment at Atyrau Oil

Refinery has

been worked

out. Let

us give

a more

in-depth description of the subsystem.

Figure 2 shows the

main menu,

where the

System Modelling menu

opens, that

is the

System Modelling menu,

has a sub-menu: System

Modelling of Processes in Sulphur Production; Mathematical modelling of basic system

blocks; Linguistic models

for processes in sulphur production; Adjustment of model coefficients.

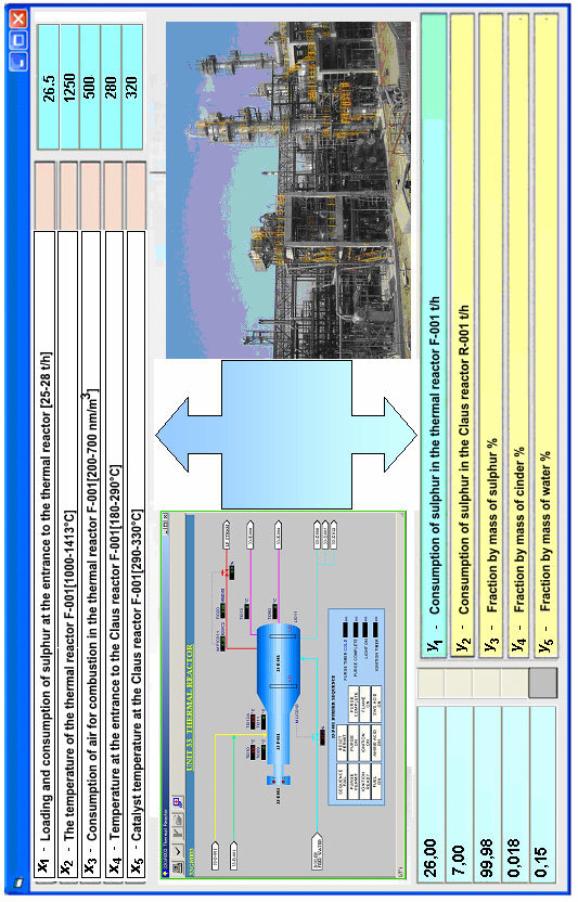

Figure 2 – Main Menu of the System being Developed

In selecting the

System Modelling of processes in sulphur production menu,

another window

opens (see

figure 3),

in which

the modelling of the process

takes place

directly.

As can

be seen

from figure

3, in the modelling regime,

the names

of the

basic regime

parameters (x1, x2, x3, x4, x5) are

shown in the upper

part for

user-friendliness of the interface. These are then changed

by the

process of modelling and

the search

for an optimal working

regime for

systems of sulphur production units.

The menu

includes change

intervals for

each of the regime

parameters.

There

is a corresponding window on the right side in order to change each of the

parameters x1, x2, x3, x4, x5

![]() At

the bottom of the window, the results of the modelling – the value of the

output parameters of the process y1,

y2, - the volume of product output from the thermal reactor and the

Claus reactor, and also the quality indicators for the intended product - y3,

y4, y5 – the fraction by mass of sulphur, cinder and

water accordingly are shown. In order to work out the new values of the output

parameters on changing the input parameters, then the button -

At

the bottom of the window, the results of the modelling – the value of the

output parameters of the process y1,

y2, - the volume of product output from the thermal reactor and the

Claus reactor, and also the quality indicators for the intended product - y3,

y4, y5 – the fraction by mass of sulphur, cinder and

water accordingly are shown. In order to work out the new values of the output

parameters on changing the input parameters, then the button -

which is next to the corresponding

yj, j=1,5 must be pressed.

Figure 3 shows the results of the

search for an optimal working regime for the sulphur production unit (a manual

search for optimal working regime).

Thus, with the help of this

sub-system, changing the value of input parameters and determining the

corresponding value of output parameters, that is system modelling of various

working regimes of basic inter-related systems of sulphur production units, we

can find the optimal regime for processes for sulphur production, that is

determine the value of regime parameters which ensure the optimal (critical)

value of output parameters.

The regime described requires the

experience and knowledge of the user, and also time, and so is not convenient

for production workers. In order to make use of this system convenient in

industrial conditions, a system optimisation sub-system is formed, which is

based on the models which have been constructed for technological systems and a

set of inter-active algorithms for the resolution of multi-criteria problems in

the optimisation of working regimes for technological installations, taking

into account the presence of fuzzy input data.

IV Conclusions

Thus,

in this paper the structure of and certain basic functional blocks for

information systems for the optimisation and control of sulphur production

units is worked out, and a sub-system for the modelling of sulphur production

processes is formed. The main results of the programme to implement the

sub-system modelling of working regimes for sulphur production units are given.

At

the present time, a programme to implement various multi-criteria optimisation

algorithms which take into account fuzzy input data, and which in doing so make

use of modification of various compressed schemes for decision making is being

carried out. These algorithms allow the user to solve the optimisation problem

in a user-friendly manner, that is the search for the values of input

parameters which provide for the optimal value of output parameters and

criteria is automatised.

References:

[1] B.B. Orazbayev, New

Information Technology for

Oil Refining, Kazakhstan Scientific News,

issue 5, 1998, pp 51-54

[2] L.A. Zadeh Out line of a new approach to the

analysis of complex systems and decision process//IEEE Trans, on SMC-Vol. 3, N 1.-

1973. - P. 28 44.

[3] K.N. Orazbayeva, Computer Systems

for Correct

Decision Making

using Modelling and

Optimisation in Oil Production and

Oil Chemical Engineering, MNPK

Collection of Research Papers,

The Role

of Scientific and

Engineering Systems

in the

Development of the Oil

and Gas

Industry, - Atyrau, 2010,

pp 71 – 77

[4] G.S. Pospelov, D.A.

Pospelov, Artificial Intelligence – Application Systems, Moscow,

Znanie, 1985,

p. 195

[5] B.B. Orazbayev, Mathematical Methods

for Optimal

Planning and

Management in Industry, - Almaty, Gilim,

2000, p. 200

[6] Dubois D., Prade H. Fuzzy sets and systems. Theory and application. //Acad.

Press. N-York, 1980.

[7] K.N. Orazbayeva, R.G.

Sarmurzina, A.T.

Mukhamedzhanov, The

Arrangement of Multi-Criteria Optimisation Problems for

Technological Processes in the Production of Benzol, and

Methods for

their Resolution Based

on the

Knowledge and

Experience of the Decision Maker.

Scientific Journal

Vestik, NAS

RK, Physics

and Mathematics Series,

2010. No.

2, pp 31-26

[8] A.S.

Rykov, B.B.

Orazbayev, Problems and

Decision Making

Methods. Multi-criteria Fuzzy

Selection, - Moscow, MIS&S, 1995,

p. 124