UDC 622.271.3:012.3.001:622.281.424

Yerkin Iskakov, Ph. D., Master of

Mining Kazakh National Technical University named after K.I. Satpayev.

Construction of stations of columned type of the

subway in Almaty.

Construction

of stations by underground way belongs to the most difficult types of works in

subway construction as it is connected with the device of a complex of the

interconnected constructions and disclosure of developments of big section.

Construction conduct in such technological sequence not to allow a deposit of

the terrestrial surface, buildings dangerous to safety and constructions, and

also a deposit of underground communications of the municipal economy located

above station. Motions of

the soil massif and a flash of a roof of developments have to be minimum.

At

construction of stations by underground way use usually working mine trunks,

but also inclined (esñalator) tunnels, and in some cases ventilating

trunks and distillation tunnels can be used.

The

main (platform) part of station constructs the line method providing a

continuity of maintaining all complex of works in strict technological

sequence. Thus use the principle of the maximum combination of separate types

of works in time. Such organization of works provides the smallest duration of

construction.

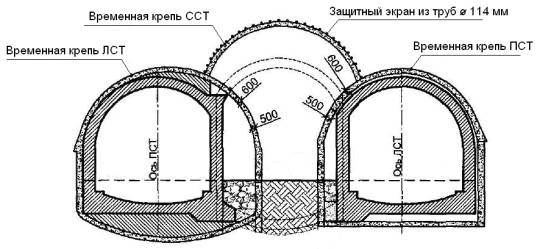

Three-vaulted

stations construct by a consecutive driving of three station tunnels. At first construct lateral tunnels, and then

— average.

In

not rocky soil putting pressure from a forehead of a face, a construction

conduct with a preliminary driving the pilot tunnels, by means of boards or banquette way.

For

a possibility of management of the provision of designs an cast in-situ lining

on station distance a driving of tunnels of three-vaulted stations with

monolithic ferroconcrete cast cast in-situ lining

conduct in one direction. At a construction of stations in unstable soil a

driving of the second (on sequence of a construction) a lateral tunnel not less

than 30 m concerning the first, and an average — with lag conduct with lag not

less than 50 m concerning the second lateral tunnel.

The

way of development and face fastening at construction of stations establish

depending on properties of developed soil. At a driving of station tunnels in

the banquette way soil develops tunnel

excavators with a ladle of active action.

Development

of a face at a driving of separate station tunnels of three-vaulted stations

conduct, as a rule, on width of 1 m.

Construction

of an cast in-situ lining of lateral tunnels of three-vaulted stations conduct

usually closed rings, and with the party turned to average part of station,

along with usual elements establish the elements entering subsequently into

structure of the main bearing design (a column, randbalka and basic beams).

In

places of future passes in an cast in-situ lining carry out temporary fastening.

At

the device of a monolithic ferroconcrete cast in-situ lining of lateral tunnels only vertical

ellipticity (increase in vertical diameter) is allowed.

Average

station tunnel pass with acceptance of necessary measures for prevention of

deformations of an cast in-situ lining

of lateral tunnels and shifts of columns.

For

this purpose in lateral tunnels establish steel racks from metal pipes, and on

the average a tunnel executions from metal pipes.

Monolithic

concrete or ferroconcrete elements of an cast in-situ lining of station erect separate sites with

application, as a rule, the mobile mechanized

or inventory collapsible timbering’s and other specialized equipment

(pneumoconcrete placers, concrete pumps, mechanical of a timbering).

Length

of sites of concreting depends on the accepted way of a construction of station

and construction of elements of an cast in-situ lining.

Sequence

of a construction of station of columned type on the NATM technology with a

ferroconcrete monolithic cast in-situ lining

the following:

• pass lateral station tunnels

in the way of the bottom ledge with lag of a face of the second tunnel not less

than 30 m concerning the first;

Driving

of the second (on sequence of a construction) a lateral tunnel conduct with a

reinforcement of the arch of the first tunnel vertical racks from metal pipes

with a diameter of 300 mm, establishing through 1,5 m on two racks with a

crossbar.

Racks

establish on 15 m ahead concerning a face of the second tunnel. Racks of

temporary fastening in the second lateral tunnel establish before a

construction of an average tunnel.

• carry out in sequence from the cross camera a waterproofing of

lateral station tunnels the PVC film;

• carry out step by step a

monolithic ferroconcrete cast in-situ lining of lateral station tunnels;

• carry out in lateral station

tunnels step by step monolithic ferroconcrete columned and crossbar ranks;

Each

part concrete in 2 stages. At 1 stage concrete a ferroconcrete tray at length

of a part of a mobile timbering.

Concreting

of a site of a wall and the arch conduct continuously by means of the pneumonic

supercharger. Breaks when concreting (on horizontal seams) shouldn't exceed 2

h.

The

device of working seams is allowed only on a horizontal axis of a tunnel. At the same time conduct concreting of a

site of a columned and crossbar row continuously by means of the pneumonic

supercharger. Breaks when concreting (on horizontal seams) also shouldn't

exceed 2 h.

After

a set concrete of design durability makes concreting of the following part.

• calotte an average station

tunnel from the cross camera pass the first 9 m in the mountain way, and the

subsequent part pass the NATM method on 7 m in temporary shot concrete fix;

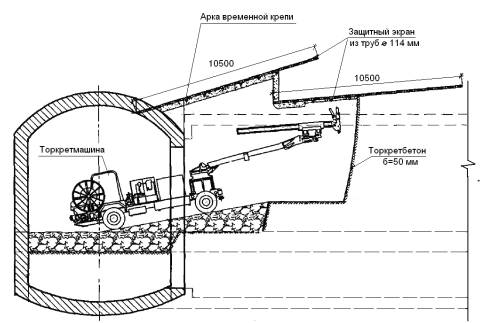

Figure 2 - Technology of a driving of station of the subway of NATM

• carry out in sequence from the cross camera a

waterproofing of the top arch

part of an average station tunnel the PVC film.

• carry out step by step part on

10 m a monolithic ferroconcrete cast in-situ lining of the top arch of an average tunnel with the device of knot of

an bear on on columned and crossbar ranks of lateral tunnels;

• pass in temporary shot

concrete fix strosse an average station

tunnel on the first part – 9 m, on the subsequent – 7 m with installation of

executions of temporary fastening from the metal pipes Æ300 mm;

• carry out a waterproofing of a

part of the lower arch part of an average station tunnel a method of drawing

waterproofing composition;

• carry out step by step part on 8

m a monolithic ferroconcrete cast in-situ lining of the return arch of an average tunnel with the device of knot

of interface of the arch with a basic beam of a columned and crossbar row;

• carry out dismantle of executions

temporary fix.

Figure 2 -

Baikonur station construction with advancing supports and the NATM elements.

The

device of the next part of a monolithic ferroconcrete cast in-situ lining of an average tunnel carry out after a set

75% of durability of concrete of the previous part. Surface shot concrete,

reinforcing frameworks of a part carefully level, carry out concreting.

Temporary

filling of apertures investigate in the course of a driving and development

calotte an average tunnel. It gives the chance to give out developed soil and

to give materials through lateral tunnels.

In

the course of construction continuous control of deformations is conducted fix.