Cand.Tech.Sci. Ignatyev V.V., Cand.Tech.Sci. Kobersi I.S.,

Shapovalov I.O.

Southern Federal University, Russia

Fuzzy

control system in an automatic and automated production

One

of the most important tasks at the present time in the development of fuzzy control

systems in automatic and automated production facilities is to improve the

quality and efficiency of control.

As

rule, this problem can be solved only within the modernization projects of the

existing facilities. It should be noted that instability of the object control

and ever-changing requirements for quality regulation prevent to increase of

efficiency of control and quality of regulation.

To

solve those tasks now, a fuzzy logic is widely used, which allows in

combination with the classical methods to successfully solve the task of

increasing the quality of the control actions on the object.

When

you create a fuzzy controller, in which systems control with industrials

regulators are used as a reference, a modified fuzzy inference algorithm, which

allows to minimize a set of rules of fuzzy inference is used [1].

Any

company in upgrading its facilities tends to maximize savings. In article the

approach to the creating of fuzzy control system, based on the knowledge gained

from the previous control system is considered.

Such

knowledge can be: system deviation; differential of a deviation; integral of a

deviation; acceleration deviation.

Depending

on the selection of the variables used to build the fuzzy system and developed

algorithms of interaction, the required control action on the object is formed.

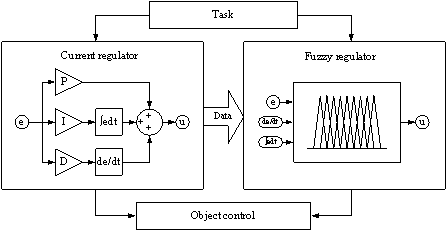

Described

above can be represented graphically in the following figure.

Pic. 1 – The block

diagram of the system control

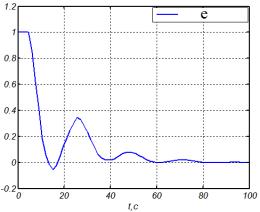

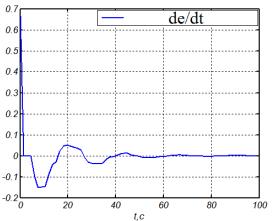

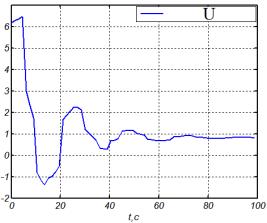

Let charts of

change of the following signals of the PID-regulator be known (pic. 2 – 5).

For the synthesis of fuzzy model it is enough to have only two signals. In our

case it is system deviation and differential of a deviation of system.

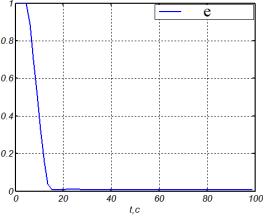

|

Pic. 2 – Deviation of the signal change |

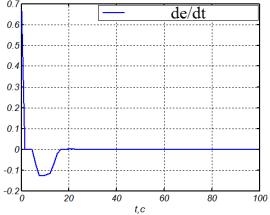

Pic. 3 – Change

of differential of a deviation |

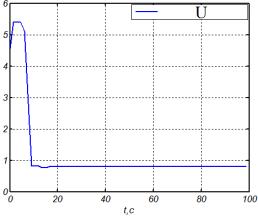

|

Pic. 4 – The

change of the control signal |

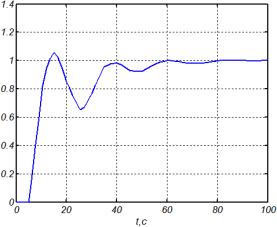

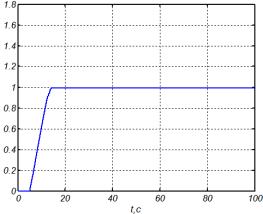

Pic. 5 – Transition process |

According to the

signals a fuzzy control system is synthesized, which is based on a modified

Mamdani algorithm with a minimum set of rules of inference. As a result, the

following charts were obtained.

|

Pic. 6 –

Deviation of the signal change |

Pic. 7 – Change

of differential of a deviation |

|

Pic. 8 – The

change of the control signal |

Pic. 9 – Transition process |

Obviously, a

fuzzy model based on the data obtained in the synthesis and simulation of the

classic model, improves the quality of the transition process.

Bibliographical list:

1. Ignatyev, V.V. Применение нечетких регуляторов, в

которых в качестве эталонных используются системы управления с промышленными

регуляторами [Text] / V.V. Ignatyev, I.S. Kobersi // Методы

и средства адаптивного управления в электроэнергетике: тематический выпуск // Известия

ЮФУ. Технические науки. – Таганрог: Изд-во ТТИ ЮФУ, 2013. № 2 (139) – 261 c.,

С. 123-127.