Ph.D., docent Sabirova L.B., undergraduate Jandarbekov N.T.

Kazakh National Technical

University after K.I.Satpaev

Kazakhstan, Almaty city

RESULTS OF EXPERIMENTAL STUDIES

APPLICATION OF SELECTION DEMULSIFIERS

Oil slime (sample ¹6) was

heated in a bath at 70 ° C in a conical glass flask of 100 ml during 30-40 min.

by periodic hand mixing. Average sample of slime is dispensed into glass-graded

sediment tube of 50 ml. One of the samples is considered to be as a test sample

(it is not dosed a reagent). The other are dosed the following reagents:

- sediment tube ¹2 - Daufaks

BB - dosage of 1000 g / t;

- sediment tube ¹3 - Hercules

1017 – dosage of 1000 g / t;

Reagents were selected by HF

dielkometric method (pp. 2.6.).

Then, every sediment tubes are

hand mixed during 1 min., and their contents are transferred to the centrifuge

tubes.

Experiments were conducted in

two series: in the first series before centrifugation all samples were treated

in a microwave oven (operating frequency is 2.4 MHz, power 800 W, during 1

min.). Field processing time is chosen so that the sample is not boiled up in

order to avoid the negative effect of SHF field. After the SHF of EMF

(electromagnetic field) treatment, the tubes were centrifuged at 3000 rev / min

during 10 minutes. In the second series, the tubes were centrifuged without

field processing.

Because of centrifugation in

the tubes, there are formed three coating: oil, sediment (mechanical

impurities), water. Thereafter the oil and water are carefully transferred into

corresponding separator funnels. To maintain the temperature of the treated

product and a better separation of the water the separator funnels are placed

in a water bath (at 80° C) for 10-15 min.. Settled water is drained. In the oil

water content is determined (GOST 2477-65, Dean and Stark method) and

mechanical impurities (GOST 6370-83).

The scheme and the

experimental results are presented in Figure 1 and Table 1. From the presented

results it is shown that the maximum efficiency was achieved by SHF treatment

of oil slime with the addition of the reagent "Hercules 1017" (1000 g

/ t) with the following separation in centrifugation (3000 rev / min).

It should be noted

that the results for the two studied demulsifiers are not very different from

each other (Table 1), so

demulsifiers

"Daufaks DF" can also be recommended as an enough effective demulsifiers

Demulsifiers

1000 g/m3

![]()

Demulsifiers

1000 g/m3

Figure 1 – The

scheme of the laboratory experiments.

Table 1

|

|

Without of SHF treatment |

With SHF treatment |

||

|

Demulsifiers |

Content of irreducible water, % |

Mechanical impurities, % |

Content of irreducible water, % |

Mechanical impurities, % |

|

Daufax DF |

5D |

0,470 |

2,6 |

0,22 |

|

Hercules1017 |

4,3 |

0,40 |

2,0 |

0,20 |

When oil slime treating by SHF

of EMF without adding the reagent, the water content in treated products was

9.5%.

Further work was

carried out to study the optimal dosage of reagents "Hercules 1017"

and "Daufax DF", as well as the selection of the initial temperature

of the oil slime treatment. Results of the studies are presented in Figures 2

and 3.

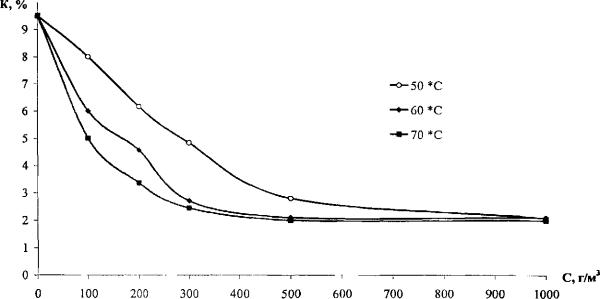

Figure 2 - The

dependence of the water content in processed products, depending on the dosage

of the reagent "Hercules 1017" with different initial temperature of

the oil slime treatment.

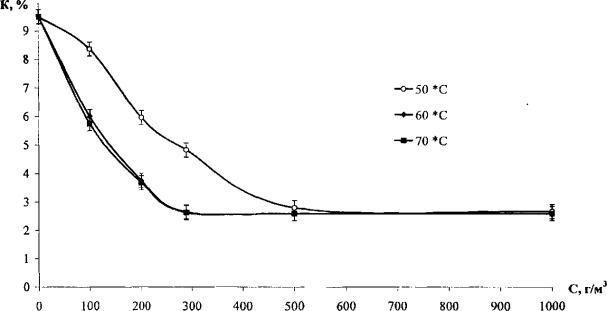

Figure 3 - The

dependence of the water content in processed products, depending on the dosage

of the reagent "Daufax DF" with different initial temperature of the

oil slime treatment.

According to the results, it

can be argued that the optimal dosage of reagents is 300 g / t, and the

temperature of the initial treatment can be recommended 60° C

The list of references:

1. Sayakhov F.L., Zinnatullin

R.R., Sufyanov R.R. and others. High-frequency dielectric spectrometry for the

selection and performance evaluation of inhibitors application of the ARPD in

the production fields of "Archangelskgeoldobycha" // Petroleum

Engineering, 2002. ¹2. - P.27 -31.

2. The selection method of

potentially effective reagents for the prevention and removal resin paraffin

deposits. Sayakhov F.L., Zinnatullin R.R., Sufyanov R.R. and others. // Patent

for an invention RU ¹2186202S17E21V 37/ 06. – Published in B.I. 2002 ¹21.