Технические науки

Nurushev

S , Ph.D.

Koctanai state University. A.Baitursynov

Justification of milling modes for surface treatment

of solonetzes.

Annotation

The

analysis was carry out according to processing technologies above

solonetsz layer, there is method of determining the limit

modes milling at fallow and half fallow processing systems .

Creating facilities for the growth and development of grass on solonetz

lands , along with other factors depends on the structure of the soil layer

above solonetz created as a result of

tillage impact their working bodies ,

wheel implements tractors. Here

with soil clods break into smaller. Spray the soil , are known to adversely

affect its properties agro-physical , a Northern Kazakhstan conditions leads to

the wind erosion . Above solonetz humus layer is the most valuable plants and

therefore requires careful handling during processing. With this particular

relevance and importance is the mode selection milling machine [1].

As the main constraints milling modes , must obviously be taken

thresholds quality processing , in particular , the degree of crumbling of soil

erosion and the content of hazardous particles. Studies on the identification

and justification of these indicators in northern Kazakhstan has not previously

been conducted.

However, in-depth studies of the dynamics of the structural units of

above solonetz layer soil destruction

after basic processing taking into account the factors listed in SpbIME

held on solonetzes Baraba lowland in 1970 ... 1973. [1 ] . In particular,

proved the high efficiency at this milling operation on agrotechnical , energy

and economic indicators compared with disking and recommended the following

limits on the degree of crumbling soil treatment at the main content of soil

fractions to 50 mm should be in the system a couple of 40.5 ... 54 1, half

fallow - 58.6 ... 68.8 % , fractions of 20 mm - 34.0 , respectively 41.0 and

53.0 ... 61.0 ... %.

Dynamics of changes in the soil structure in the system of fallow and

half fallow, according SibIME [2] , clearly characterizes the subsequent

mechanical impact : treatments. In the area for a couple of Baraba after

primary treatment is carried out before sowing three operations , while the

total number enucleating sixfold and reconsolidation one track - only ten

passes aggregates. On half fallow be four operations , including a sixfold

shelling , five times harrowing , and rolling in one track - a total of 12

passes aggregates.

For an area of Kazakhstan has three operations : crop field into a

single track, double treatment steam harrow BIT- 3 and double disking plow

harrow LDH -10 - just five passes aggregates [3].

From these data it is evident that the total number of treatments in

this area is less than 2 times or more, which is mainly due to the difference

in the soil. In our conditions, the soil surface layer sod is weak , prone to

dusting .

In addition to the technology options SibIME not considered the impact

on the structure of the soil layer over solonetz operations deep treatment after milling, in which the wheels of

the tractor ripper , its working bodies also lead to changes in the original structure

of the soil. It acquires special importance in relation to the basic -block

tools for processing with wheel tractors "Kirovets" .

Analysis on the effect of milling quality tillage indicates identity

patterns obtained under different conditions. According SibIME , mill feed is

recommended on the knife within 7 ... 10 cm to provide the desired degree of

crumbling soil and minimum spray []. When using these modes in our conditions

observed excessive spraying soil , a large amount of erosion-prone particles.

However, given the limits of crumbling soil are achievable when milling with a

larger serving knife, i.e more forward speed of the machine. It is necessary to

seek and to reduce the circumferential speed frezbarabana . This requirement is

an analytical and experimental study . As it is known , the degree of crumbling

soil ( K) , the circumferential velocity milling reel (Vo) and serve on the

knife (S) with other fixed parameters are interrelated by the following

empirical equations [4] :

(1

) ![]() %,

%,

(2 ) ![]() %,

%,

Where in A1, A2 , B1, B2 , C - coefficient obtained by approximation .

Since

the degree of influence on the circumferential speed of the crumbling of the

soil and feed on the knife difference find the relationship of equations (Vo)

and (S):

(

3) ![]() ,

,

When processing of virgin sod solonetzes in Kostanai region , for

example, milling reel diameter of 450 m with four knives in bilateral

translational speed of 2 m / s formulas and coefficients are as follows:

A1= 24.1 %

: a2 = 123.1 % ; в1 = 96.8 % ; в2 = 6.65 % / m , с= 1 с / m

Putting these values into equation (3 ) yields the

relationship (Vo) and (S), from which it is seen that by increasing feed blade

at a constant forward speed can reduce the circumferential velocity . And the

supply on the knife optimized degree of crumbling soil

( 4) ![]() ,

,

( 5) ![]() ,

,

|

|

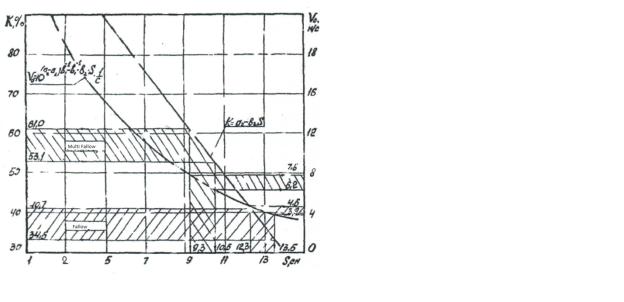

Interconnection

raising soil crumbling and milling modes with m / s ; DF = 0.45 m

Plotting these curves (see Fig. ) And overlaying limited by crumbling

soil by raising the optimal feed value on the knife , and then feed on the

knife - the values of the circumferential speed milling reel .

Point

of interconnection regimes and the quality of the cutter will be taken as a

basis for our ongoing studies to substantiate the basic design parameters of

the milling machine.

literature

1.

Zhulamanov K, S Nurushev. Using rotary instruments for continuous processing of

soil . - In the book . . Mechanization of production : processes in crop

production of Northern Kazakhstan . Alma- Ata , 1981, p.111 ... 115.

2

. Kulebakin N. Waterline machining solonetzes Baraba lowland . Nauka,

Novosibirsk, 1980, p . 88 ... 101.

3

. Methodological guidelines for soil reclamation research and development of

land reclamation projects solonetz in the Kazakh SSR . Alma- Ata , 1980, p.74

... 101.

4

. Zhulamanov K, K Nikonov , A. Terpilovsky Milling sod alkaline soils in the

Northern Kazakhstan. - Scientific and technical bulletin VIM vyp.28 , M. , 1976

, p.27 ... 29.