Технические науки/8. Обработка

материалов в машиностроении.

Kamsky

G.V. *, Kolomiets A.A.**

*Ural Polytechnic College, Russia

**Technion – Israel Institute of Technology,

Israel

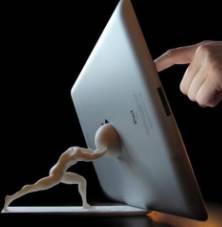

Our future in

Additive Manufacturing

New forms,

new applications, searching of new materials, all of this are the

characteristics of new modern innovative technology – Additive Manufacturing

(AM), or 3D-printing.

Like email, 3D printing is now common. It’s been embraced by all

industries as a means of product development, data visualization, rapid

prototyping, manufacturing, including distributed manufacturing and

print-on-demand services. Celebrity comedian Jay Leno uses this technology to

print obsolete parts to maintain his extensive automobile collection. Amazon

sells 3D printers and supplies through its online store to be sold to the

average consumer for realizing their own parts.

PROTOTYPING

Additive manufacturing

as scientific and industrial direction started in 1970s-1980s from morphology. It was called

prototyping.

Rapid

prototyping helps companies turn great ideas into successful products faster

than ever before. 3D printing your prototypes directly from CAD data enables

fast, frequent revisions based on real-world testing and feedback.

Nowadays

users are even could use AM without knowing CAD technologies or other special

drawing packages, using just 3D-scaners that create model for you.

ENTERTAINMENT

INDUSTRY

This

application is the most close to prototyping but also shows how AM technologies

permeated to different spheres of our life. We are waiting for a holiday,

children are waiting for a present, and a bride is waiting for a ring that no

one has.

This

technology allows to create exclusive presents, jewelry and business souvenirs.

All depends just on your design. Moreover, you can decide how many specimens

you want to print.

AM FOR

MEDICINE

Thousands of people do not realize that they have

already become a part of 3D printing revolution in medicine. According to the

report on 3D printing industry, there are more than 10,000,000 3D printed

hearing aids circulating worldwide. 3D printing technology has absolutely

improved their manufacturing process.

|

|

|

|

3D Printed Hearing

Aids: A Revolution you may have not heard about |

|

In early spring of this year, an American patient

got a radical surgery performed and 75% of his skull was replaced with a 3D

printed implant. This material was not only biocompatible but also a bone-like.

Scott DeFelice, President and CEO of Oxford Performance Materials, announced that

his company has serious plans that between 300 to 500 patients in the U.S.

alone could have skull replacement surgeries each month.

Eric Moger was the first person

to start a life once again with 3D printed

face.

The highest goal of the technology is to

save lives. From 3D printed food and plastic wrenches, technology moves

straight to artificial blood cell printing and represents the important step in

the development of artificial organ transplants since the current generation of

artificial organs lack the vascular network needed to function properly.

Scientists from Germans' Fraunhofer Institute use the particular technique that

involves artificial biological molecules printed out with a 3D inkjet printer,

then they form the shape of blood vessels.

This technology is still quite imprecise

for the fine structures of capillary vessels, so the scientists use the laser

to zap the molecules and to form the material. Real blood vessels have two

layers as well as the artificial ones, so they can form complex branching

structures.

Skin graft transplantation is nothing new in the

medicine. It has become casual but extremely painful procedure, while a part of

healthy skin is removed to cover the damaged place of a body. As 3D printing

technology has enabled scientists to play even with the most futuristic ideas,

they come up with one: to produce the artificial skin. Researchers at the

University of Toronto have developed a method of loading skin cells and various

polymers into 3D printer to artificially create thick layers of skin.

AM FOR AUTOMOBILES AND AEROSPACE

Companies which fabricate automobiles are some of the

most intense users of 3D printing in the industry. They use 3D printing for a

lot of applications and they have been doing so for years. Because there is so

much engineering and design involved in the industry and due to the sheer

number of parts required in a modern automobile, 3D printing is the ideal

technology to prototype these parts.

Concept Cars

Since quite a while, concept cars have been 3D printed.

The main application is to use the technique of 3D printing for the interior of

the car. In this way a lot of time and money can be saved.

Prototyping

car parts

Tier 1 automotive suppliers and car manufacturers use

3D printing to print the initial prototypes of parts of the car, like door

handles for example. In the beginning, this was only done for visual

prototypes, however now there are more applications being found. Prototyping

car parts helps speed up the time to market, because engineers can remove any

obstacles early in the product development cycle.

Production of

parts in small series

Examples of series production parts are quite rare. Although

there are some cars which are partially made by hand. As each car is made by

hand, minute differences mean mass production would not work here. So some

parts are uniquely 3D printed for each car.

Fit and form

testing

More and more items, like door handles, are tested by

engineering teams and also by customers. It is very useful, as this gives

people a chance to give feedback on a new part. It allows people to test the

functionality of the part, but also how it works in more complex assemblies.

Unique cards

3D printing to customize a car is also not unheard of.

Sometimes it concerns just individualized components, monograms and the inside

of the car, like the lining. But designing a car from scratch is also possible,

with a design firm. They can help create a design and hand it over to an

automotive manufacturer.

But what use is this technology for

Aerospace. Consider the wing of a conventional aircraft. The curved shape of

the wing, coupled with a source of propulsion, is what makes flight

possible. The wing, covered with an aluminum skin, is made of metal spars

and ribs that give the wing strength to ensure it does not fail in

flight. Manufacturing of these components with conventional CNC machines

always leads to a predominance of wasted material. Certainly the waste is

harvested to be recast into raw material ready to be milled once again.

Recycling material certainly saves money but it’s still expensive to return the

waste material to a site where it is to be melted and recast or rolled into

sheets and blocks of material, transportation to another site for milling parts

and then transportation of those components to another site for assembly onto

the aircraft. Every additional site adds more risk that the part will be

produced out of tolerance, possibly with catastrophic consequences. With 3D

printing, the part could be created from raw materials directly at the site

where it will be used, thereby reducing the risk of possible defects occurring

from improperly shipped components, milling by out-of-tolerance equipment, etc.

However lucrative 3D printing may seem,

safety critical +aircraft parts require certification by aviation authorities

before they can be installed on commercial aircraft. In fact, despite all

the obvious successes with 3D printing, the FAA has only just certified the

first 3D-printed part for use on a commercial jet engine*. The part is a

T25 housing for a compressor inlet temperature sensor fabricated by GE Aviation

and it will be retrofitted to over 400 GE90-94B jet engines on the Boeing 777. 3D

printing allows the part to be lighter, more complex, and made of a singular

piece instead of several fitted together. GE says that making a prototype

of the T25 would have taken a year longer using conventional manufacturing

methods.

GE is using

laser-powered 3D printers, 3D "inking" and "painting"

machines, and other advanced manufacturing tools to make parts and products

that were thought impossible to produce and which sometimes verge on art. We

see advanced manufacturing as the next chapter in the industrial revolution.

Airbus has recently announced that its new

A350 XWB includes over 1000 components manufactured by 3D printing. These are

plastic parts produced by Stratasys. The Airbus video below includes some

insight into the 3D printing facilities used to produce parts for their

aircraft.

In November 2014 NASA reported that the International

Space Station’s 3D printer had made the first 3D-printed object in space. This

is yet another in a complex list of steps needed to achieve sustainable

long-term space expeditions. To print a 3D part, not only do you need the

printer but also the raw materials. If these raw materials were available

extraterrestrially, it may be possible to achieve meaningful colonization on

Mars or other planets. What was once considered science fiction may now

be science possible.

3D- PRINTING

OF HOUSES

Scientists in California say new technology will soon allow

massive 3D printers to build entire multi-level houses in under a day.

The

process begins with leveling the area where a 3D-printed house will soon be

built, and then trenches are dug around the perimeter and filled with concrete.

A system of rails is then erected on the sides of the foundation, and the

printing contraption itself is then lowered down using a crane and fed the

building materials.

Like

traditional 3D printers, the system carefully spills out those materials layer

by layer as the machine expands to a height of roughly two stories,

consistently building upward as more concrete is unloaded. Instead of being

left with a plastic toy or, as some have made possible recently, a gun, this

process would ideally soon enough end with an entire structure created from

close to nothing.

“Using

this process, a single house or a colony of houses, each with possibly a

different design, may be automatically constructed in a single run,” the

Contour Crafting website reads. The designs take into account additions that

would need to be added after the fact, like plumbing, electrical lining and

windows, which can then be easily outfitted once the rest of the structure is

solid and standing.

CONCLUSION

Many

believe that 3D printing will revolutionize manufacturing and its industries.

With NASA printing engine parts to rockets and Boing planning to print fully

functional airplane wings it´s hard to argue. It is also easy to get carried

away, imagining a futuristic sci-fi world where everything needed around us

will be printed without taking the earlier addressed limitations into the

equation. The futures of additive manufacturing will likely involve significant

sharing of production facilities (Eitel 2013). As files are transferred

digitally, production can happen locally as close to the end user as possible.

This eliminates global shipping and the damage it brings upon the environment.

Aerospace is the industry other industries look to for a glimpse of what the

future might bring. They were the earliest adopter of carbon fiber and the

first to integrate CAD/CAM into the design process. Both of these

implementations are now commonplace throughout industries and doesn´t require

financial justification (Hiemenz 2013). There are many other examples that show

that trends in aerospace predict the future, which is reassuring for the

additive manufacturing industry. I am confident when saying that AM will

dictate manufacturing in industry in the future.

As

of today AM is widely used for product development in RD departments across the

mentioned industries, throughout all functions and processes. The most common

uses include concept models, functional prototypes, tooling and production

components. It is rapidly growing into a large-scale industry. Additive

manufacturing gives the flexibility to iterate while facilitating for faster

turnaround resulting in products arriving the market sooner, while keeping

costs down and thus increasing profit. The role of 3D printing in manufacturing

is an important ecological factor. Due to less material prepared and wasted in

the process of manufacture, AM is beneficial to the environment when compared

to traditional processes. As of today, the process of printing itself is to

energy consuming and has to be developed further. The manufacturing

technology´s success and widespread use throughout the transport industry is

inevitable. Aerospace and motor sports are leading the way, using AM for small

production parts. The technology is producing components with good material

properties at lighter weights resulting in better performance. The evolution of

3D printing won´t happen overnight, as there are problems yet to figure out.

Today, AM within production is used mainly for non-critical parts. For the

technology to facilitate the production of load bearing components there has to

be developed validation standards for material and process quality. The

sensitivity of current machines is an issue and has to be dealt with. When

printing a component several times the mechanical properties have to be stable

from one print to the next. Additive manufacturing might very well become the

de facto method of industrial manufacture in the future. While its historical

underpinnings date several decades back it´s only in recent years the

technology has been widely implemented in product development, completely

altering how and what can be made. The direct connection between designer and

manufacturing is re-established. It is believed that we will see remarkable

shift from use limited to prototyping over to production.

Literature:

1. Erik Saitre.

Development of Additive Manufacturing Technology. Implications on the design

process and the transportation industry, moving from prototyping to production.

Department of Product Design Norwegian University of Science and Technology

3. First 3D

printer reaches high street http://www.theguardian.com/

4. 3D Printing

in Medicine: How Technology Will Save Your Life https://www.cgtrader.com/blog/3d-printing-in-medicine-how-technology-will-save-yourlife

6. C. Y. Yap, C. K. Chua, Z. L. Dong, Z. H. Liu, D. Q. Zhang, L. E. Loh, and S. L. Sing Review of selective laser melting: Materials and applications. Applied Physics Reviews 2, 041101 (2015); doi: 10.1063/1.4935926