Òåõíè÷åñêèå íàóêè/1. Ìåòàëëóðãèÿ

Denysenko O.I., a Candidate of Technical Sciences

National Metallurgical

ON FORMATION OF

IMPULSE OF HIGH-SPEED DIPHASE FLOW FOR METAL-COMPOSIT SYNTHESIS

Experimental investigation of processes of encounter of

solid oxide microparticles (within the ranges of dimensions 0,01 – 20

micrometers and speeds 100 – 800 m/c) with an obstacle made from the electrode

flong as well as the analysis of physical conditions of connection of

microparticles with the surface depending on their speed and concentration are

of considerable fundamental and practical interest [1], and their results can

be used for optimization of synthesis technique of metal-composit electrode

structures.

The basic principles of the automation system of

experimental assembly for injection formation of metal-composit construction

are set forth in [2]. The principal elements of the assembly for injection

formation of metal-composit are as follows: a supersonic nozzle meant for

acceleration of microparticles to high speeds; heaters of the work substrate

and carrier gas for oxide particles; a powder consumption batcher; an

ultrasonic generator for the substrate material activation; a reaction chamber

with a placed inside control system positioning the substrate with regard to

the nozzle section; valves for make-and-break gas supply to the supersonic

nozzle and batcher.

The system operates in the following way. Having started

up the program, the experimentalist, using a

keyboard, sets a make-and-break time schedule of gas supply valves,

stepper motors of batcher and substrate positioning, the ultrasonic generator,

and desired temperature values of substrate and carrier gas for oxide

particles. After starting up the experiment, the program sends steering

commands to the peripheral devices (for example, to opening of a required gas

supply valve) according to the preset time schedule.

Necessity of economically appropriate and efficient use

of processing resources (electric power, compressed gas, powders of

electrochemically active oxides, etc.) leads to inevitability of formation and

use of oxide particles in experiments on research into their injection upon

formation of metal-composite electrode of diphase flow impulses (see Fig. 1).

Fig. 1. A free-flowing out into atmosphere diphase flow impulse

visually watched upon frame-by-frame scanning (the time magnifier method).

By the same reasons the most attractive seems the use of

diphase flow impulses, that are limit short with regard to the equipment that

forms them, and in the presence of which injection of oxide particles into

metal-composit is observed. The specificity of diphase flow impulses formation

upon short intervals of the gas supply valve opening at the supersonic nozzle input

determines the necessity of placing of the injected matter powder between

nozzle and valve.

Computer control of the valve is fulfilled by setting or

changing of the logic signal level on the electronic switch controller through

which the power winding of the valve is connected to the electric power source.

It was defined experimentally that upon duration of computer valve control

signal less than 3∙10-2 c,

gas valve opening does not happen, probably, as a result of transient

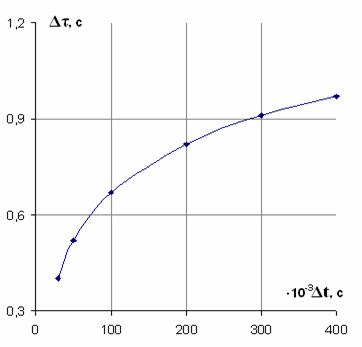

sluggishness. In consequence of the same reasons the dependence of interval Δτ of the gas valve opening at the

supersonic nozzle input on the duration Δt of computer signal of this valve

control, shown graphically on figure 2, has explicit nonlinear character.

Fig.

2. Dependence of interval Δτ of the gas valve

opening at the supersonic nozzle input on the duration Δt of computer valve control signal.

The information about functional character and type (see

Fig. 2) of dependence of the interval of openness of the gas valve (used for

supplying gas carrrying oxide particles and controlled by computer) on duration

of the steering command is useful both for manual control of the high-speed

diphase flow impulse and for construction of the automation system of dynamic

control of the process of metal-composit electrode synthesis.

Literature

1. Denysenko O.I. Mesoscopic Aspect of Structural

Engineering of Metal-composit Cathode // Materials of the First International

Research-and-Practical Conference “News of Scientific Thought – ‘2006”. – V. 5. Technical Sciences. – Dnepropetrovsk: Science and Education, 2006. – P. 3-5.

2. Denysenko O.I., Kalinushkin Å.P. Automatic Control of Firmware Complex for Nanostructure Synthesis // Collected works of the 13th International Scientific and Technical Conference on Automatic Control (Automation-2006). – Vinnytsya, UNIVERSUM-Vinnytsya, 2006. – P. 190.