Artur Mantel1, Nikolay

Barashkov2, Irina Irgibayeva1, Anton Kiriy3

and Volodymyr Senkovskyy3

1L.N.

Gumilyov Eurasian National University, Astana, Kazakhstan

2Micro

Tracers, Inc., San Francisco, California, USA

3Leibniz

Institute of Polymer Research, Dresden, Germany

Free-radical quaternary

copolymerisation of styrene, 4-vinylbenzoic acid, 9-vinylanthracene and

2-vinylnaphthalene: composition of prepared copolymers

Introduction

This study is devoted to the synthesis and

investigation of styrene and its carboxy-derivative copolymers containing

naphthalene and anthracene chromophore fragments into polymer chain. Copolymers

of styrene, including chromophore-containing copolymers has been previously

used as materials for efficient plastic scintillators1-4. Analysis

of previously reported data on copolymerization of styrene (Sty) with

comonomers, such as 9-vinylanthracene (9VA)

and 2-vinylnaphthalene (2VN) shows that 2VN and Sty possess close constants of

copolymerization5,6 and therefore all 2VN participates in reaction.

In contrary, 9-VA has been found to be less reactive than Sty and its

significant part (at least 50% according to data7) does not

participate in reaction of copolymerization. There are some experimental

evidences that besides reaction of copolymerization, 9VA is capable of

interacting with styrene in the following ways 3,8: a) addition of

styryl or polystyryl radicals to the

meso-position of the anthracene ring; b) addition of one of several molecules

of styrene to the vinyl group of 9VA to form low molecular weight products;

substitution of hydrogen atoms in the meso-position of the anthracene ring by

styryl or polystyryl radicals.

There are also

numerous papers describing the synthesis and application of carboxyl-containing

styrene-based copolymers. Carboxyl group is often used for the subsequent

modification9, which explains our intention to introduce the carboxy

group into the chromophore-containing polymer. Carboxylic group is introduced

into copolymer by the means of copolymerization of styrene with 4-vinylbenzoic

acid10 (VBA). Taking into account the available literature data, we

made an attempt to synthesize the quaternary copolymer, containing the predicted

ratio of the four monomers in the chain.

Experimental

Materials. All reagents were purchased

from the Aldrich Chemical Co. 2-vinylnaphthalene(2VN), 9-vinylnaphthalene (9VA)

and styrene (Sty) were purified from stabilizator, products of oligomerization

by silica column with hexane as eluent;

4-vinylbenzoic acid (VBA) was recristallized from water: ethanol (3:7 v/v);

2,2,6,6-tetramethyl-1-(1-phenylethoxy)piperidine was prepared from TEMPO

and (1-bromoethyl)benzene by the method presented below.

Instrumentation. Gel

permeation chromatography (GPC) was used to determine the molecular weights and

molecular weight distributions, Mw/Mn, of polymer samples with respect to

polystyrene standards. The system configuration: THF with flow rate 1.0 ml/min.

HPLC-Pump, Ser. 1200, Agilent Technology; ETA-2020 – RI – and

viscosity detector from Fa.Bures; MALLS detector from Wyatt.

1H NMR spectra

were collected on the device «Bruker Bio Spin» (1H 500 MHz, 20 0Ñ, solvent

-CDCl3, TMS - an internal reference).

UV/vis absorption

spectra were measured on Perkin Elmer Lambda 800 spectrophotometer.

Synthesis of

2,2,6,6-tetramethyl-1-(1-phenylethoxy)piperi-dine. To the round-bottomed flask containing 0.5008 g of copper

bromide, which is closed with a septum and filled with argon , the mixture of 0.73

ml N,N,N',N'',N''-pentamethyldiethylenetriamine and 10 ml dry toluene was added.

To another flask equipped with a magnetic stirrer a mixture of 0.538 g (1-bromoethyl)benzene

and 0.5 g ÒÅÌÐÎ was added. The air was evacuated from the reaction mixture, 10

ml of dry toluene was added and a reaction flask was flushed with dry argon.

The content of first flask was added slowly to the content of second flask and

mixture was stirred for 1 hr at temperature 50 0Ñ.

The obtained

solution was purified by chromatography using toluene as eluent. After evaporation of toluene, the

oily liquid was slowly crystallized in the cold. The resulting white crystals were

dried in vacuum and characterized by 1H

NMR.

Copolymerization of styrene 2-vinylnaphtalene, 9-vinyl-anthracene

and 4-vinylbenzoic acid.

Mixture of VBA (5.5 mmol, 0.815g), TEMPO (0.031 mmol, 0.00478g) and 2,2,6,6-tetramethyl-1-(1-phenylethoxy)piperidine

(0.304 mmol, 0.07940g) was dissolved in 8 ml (69.59 mmol, 7.248g) of Sty. Mixture

was divided into two equal parts. One of them was placed in a flask containing

9VA (0.038 mmol, 0.00784g) and 2VN (0.142 mmol, 0.02189g). On next step both

parts were subjected to three freeze

thaw cycles to remove oxygen, and flasks were flushed with dry nitrogen. Both

mixtures were stirred overnight at the temperature 130 0C. Prepared

copolymers were dissolved in the system CH2Cl2:CH3OH 9:1 and precipitated in

hexane three times. Polymers are drying to constant weight in vacuum at

temperature 70 0C and characterized by 1H NMR.

Results and Discussion

Figure 1 shows the polymerization process and chemical structure of prepared

quaternary copolymer (CP). In case when l=n=0,

the corresponding copolymer without chromophore fragments (MX) has been

prepared.

Figure 1. Copolymerisation of styrene

2-vinylnaphtalene, 9-vinylanthracene and 4-vinylbenzoic acid.

According to

GPC data, the Mw of copolymers CP and MX are

30,000 and 30,400, respectively. The determined molecular weight

distributions have been equal to 1.09 and 1.16 for CP and MX, accordingly. The

amount of VBA in copolymers has been determined by the titration of solution CP

or MX in THF after neutralization with a small excess of NaOH/ methanol solution by aqueous 0.1 N HCl

solution

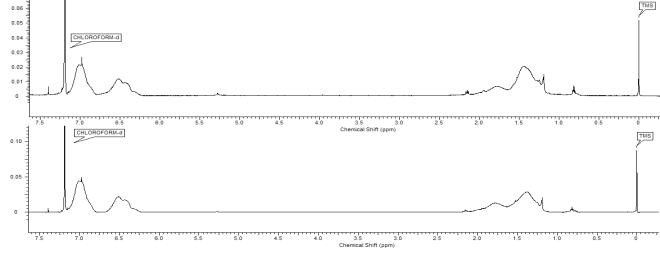

1H NMR spectra of both polymers are depicted

in Figure 2. It is obvious that the

areas of aromatic protons for both polymers are identical. That´s why it

was difficult to determine the amount of 9VA, 2VN and VBA in CP by 1H

NMR spectra.

Figure 2. 1H NMR spectra of

CP (above) and MX (below).

Therefore we used the UV-absorption spectra for

quantifying the concentration of anthracene and naphthalene fragments into

polymer chain of CP using the system CH2Cl2:CH3OH

(9:1 v/v) as solvent. Figure 3 shows the absorption spectra

of 4 different concentrations of copolymers CP and MX in the spectral region

300-425 nm which has been used for determination of anthracene concentration.

Figure 3. UV/vis absorption spectra of

CP (left, concentration for spectra 1 is 144.7 g/l, 2 – 72.35 g/l, 3 – 36.175

g/l, 4 – 18.087 g/l) and MX (right, concentration for spectra 1 is 220.5 g/l, 2

– 142.1 g/l, 3 – 71.05 g/l, 4 – 35.525 g/l).

It was found that the absorption maximum around 350 nm

(peak I on Figure 3) can be used for quantitative determination of anthracene

content due to the linear relationship between the intensity of this band and

concentration of polymer in solution.

Another spectral region (220-290 nm) and other

concentrations of copolymer CP in CH2Cl2:CH3OH

(9:1 v/v) solution have been chosen for quantifying content of naphthalene

groups in this copolymer (Figure 4).

Figure 4. UV/vis absorption spectra of

CP (left, concentration for spectra 1 is 0.05 g/l, 2 – 0.043 g/l, 3 – 0.036 g/l,

4 – 0.029 g/l, 5 – 0.018 g/l) and MX (right, concentration for spectra is 0.049

g/l, 2 – 0.042 g/l, 3 – 0.035 g/l, 4 – 0.028 g/l, 5 – 0.0175 g/l).

In order to determine which wavelength should be used

for quantifying naphthalene fragment concentration in CP we compared the

absorption of copolymers CP and MX in the spectral region between 220 and 290

nm (Figure 5). It seems that the

intensity of absorption at 232 nm is the most distinctive feature in spectrum

of copolymer CP which allows to provide the quantitative estimation of

naphthalene contribution in the absorption. Figure 5 shows as well the absorption spectrum of model compound 2-ethylnaphtalene

which has been chosen for making a calibration graph for quantifying the

naphthalene content in copolymer CP.

As for determination of antracene content we used

another model compound – 9-methylanthracene. Table 1 summarizes data of spectrophotometrical evaluation of

naphthalene and anthracene fragments content in copolymer CP in comparison with

amount of corresponding monomers 2VN and 9VA which were used as starting

materials for copolymerization. It presents as well the data on content of

carboxyl groups in copolymer CP in comparison with concentration of VBA

introduced in copolymerization process.

Figure 5. Comparison (left) and

difference (solid line, right) between the absorptions of CP (dotted line) and

MX (solid line, left) in comparison with 2-ethylnaphthalene (stick-dotted line)

as a model compound.

Table 1. Content of monomers 9VA, 2VN and VBA in

reaction mixture and in copolymer.

|

Monomers |

Mol. % in reaction mixture |

Mol. % in copolymer CP |

|

9VA |

0.1 |

0.0034 |

|

2VN |

0.37 |

0.037 |

|

VBA |

7.26 |

9.08 |

Conclusions

Free radical

copolymerization of styrene, 2-vinylnaphthalene, 9-vinylanthracene, and

4-vinylbenzoic acid has been reported.

Concentration of carboxy groups, as well as concentration of naphthalene and

anthracene derivatives in reaction mixture and determined concentration of

corresponding fragments in copolymer have been compared. It has been found that

copolymer contains about 30 times less of anthracene fragments, about 10 times

less of naphthalene fragments than amount of corresponding comonomers which

have been introduced into reaction.

References:

1.

Moser S.W.; Harder W.F.; Hurlbut C. R.; Kusner M. R. Radiat.

Phys. Chcm. 1993, 41, No. l/2. pp. 31-36.

2.

Grigor'eva V.I.; Gunder O.A.; Krasovitskii B.M.; Petrova I.B.

J. Appl. Spectros. 1968, 5, pp. 535-536.

3.

Barashkov N.N., Gunder O.A. Fluorescent Polymers, Ellis Horwood, UK, Chichester, 1994.

4.

Harmon J.P..; Gaynor J.F.; Taylor A.J.;

Radiat. Phys. Chcm. 1993, 41, No. l/2. pp. 153-159.

5.

Price, C.C.;

Halpern, B.D.; Voong, S. J. Polymer Sci. 1953,

11, pp 575-582.

6.

Loshaek S.; Broderick E. J. Polymer

Sci. 1959, 39, pp 241-247.

7.

Katz D. J. Polymer Sci. A. 1963,

1, pp. 1635-1643.

8.

Cherkasov A.S., Voldaikina K.G., Vysokomolek.

Soed., 1967,7, pp.175-179.

9. Tsubokawa N.; Kobayashi

K.; Sone Y.; Shimomura M. J. Macromol. Sci. A – Chem. 1988, 25, pp. 1475-1486.

10.

Prasath R.A.; Margarit-Puri K.; Klapper M. J. Appl. Polymer Sci. 2007,

103, pp. 2910–2919.