Agriculture / 4.Technologies

storage and processing of agricultural products.

Mahacheva E.V.

Siberian University of Consummer Co-operatives (SUCC), Russia

Effect

of cold storage on the quality indicators of minced meat products

Minced

meat products are multicomponent and active systems, in which both are

microbiological and physico-chemical reactions which have a significant effect

on the taste, texture and shelf life of the product. Reduced quality of

semi-finished and finished products of minced meat is mainly due to lipid

oxidation and microbial growth, which can get into the product at any stage of

the process.

The

rate of oxidation of lipids is dependent on the temperature of storage

products, exposure to oxygen, and the chemical composition of the initial state

of the raw materials used, heat treatment. Obviously, most are highly

susceptible to oxidative damage of minced meat products that contain a lot of

moisture and fat.

Therefore,

the aim of this study is to obtain data on the physico-chemical and

organoleptic parameters culinary multi minced meat products prepared according

to «Cook and Chill» technology, and change these parameters during cold

storage. «Cook and Chill» technology is defined as a catering process whereby

meals or meal components are fully cooked, then cooled by controlled chilling

and subsequently stored at a temperature above freezing point (i.e.≤3

°C), prior to regeneration and/or service.

As

objects of study selected four minced products with different combination of

meat ingredients and different fillings, made on «Cook and Chill» technology: ¹1 - minced chicken (70%), white bread

(9%) and other components (21%); ¹2

- minced chicken (30%) + minced pork (40%), boiled eggs (20%) and other

components (10%); ¹3 - minced

chicken (55%) + minced beef (40%) and other products (5%); ¹4 - minced chicken (22%) + minced beef

(18%) + minced pork (20%), boiled rice (10%) and other components (30%).

Cooling

temperature of the samples was 4±2°C, regeneration products was carried out in

Rational Combi Steamer Mode Self Cooking Center (SCC) «with termokernom"

to the temperature in the center of the product 65 º C. The studies were

conducted by standard methods: peroxide value - by oxidation of hydriodic acid

peroxides contained in the fat, acid number - Titration of free fatty acids in

the ether-alcohol solution of an aqueous alkaline solution of fat. Organoleptic

evaluation minced culinary products at the control points (0, 24, 48, 72 h) was

carried out according to GOST 9959-91 on a 9-point scale (appearance, color,

the cut, smell, taste, texture, juiciness), 1-4 - negative quality minced meat

product, 5-9 - positive.

In

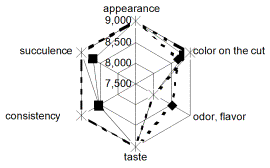

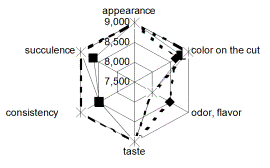

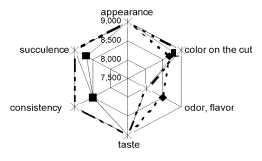

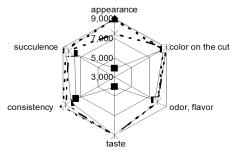

Fig. 1 shows the results of sensory evaluation of samples during storage.

a b

c d

![]()

Fig.

1. Profilograms sensory evaluation minced meat products: a - freshly cooked

product, b - recovered product after cooling; c - recovered product in 24-48

hours of storage; d - the product recovered after 72 hours of storage

Found that in the range of 0-48 hours of storage organoleptic changes

are observed. After 72 hours of storage for your reference (formulation number

2 and number 4) is different from the freshly - has moist crumbs form, in a few

places is peeled from the product; consistency - less juicy. Smell and taste

for all products, except for prescription number 2 - peculiar to them. In item

number 2 there is a weak non-specific product fresh flavor.

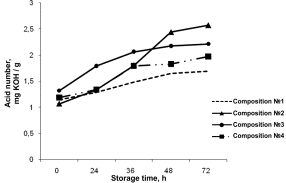

In Fig. 2 shows the results of determination of the peroxide and acid

number of lipid chilled minced meat food products during storage.

a b

Fig.

2. Peroxidation (a) and acid (b) number of lipid chilled minced meat food

products during storage

In chilled culinary products number 1, 2 and 4,

peroxide value slightly increased, not to exceed the recommended standards. In

the samples prepared according to a recipe number 3, after 72 hours of storage

has been a sharp increase in this index, not going beyond the level of normal

(Fig. 2a).

In all of the products in storage, an increase in the

acid number of fat due to the hydrolysis process and the accumulation of free

fatty acids. This change is especially pronounced in the recipe number 3 (after

36 h acid number has increased more than 2-fold) (Fig. 2b). On

organoleptic changes are not affected. Perhaps the intensity of hydrolytic

processes can be associated with humidity of products and a ratio of fat

components in the formulation.

Thus, the results of studies lead to the conclusion

about the possibility of the production and storage of prepared multicomponent minced

meat products prepared according to «Cook and Chill» technology, with no

significant change in the quality of the source within 48 hours (t=4±2 ºC).