Danilov F.I., Vasilieva O.O., Smenova I.V., Protsenko

V.S.

Ukrainian State University of Chemical Technology,

Dnepropetrovsk, Ukraine

Iron electrodeposition from methanesulfonate

electrolyte

Electrodeposition of iron and its alloys has been

widely used for various engineering applications such as electrotypes,

electroforming, repairing worn and corroded machine parts, magnetics components

in computer and electronic industries, microelectromechanical systems and so on

[1-5]. Iron electrodeposits are usually obtained from acidic sulfate, chloride,

fluoroborate and sulfamate Fe(II) electrolytes, although weak-acid Fe(III)

baths [6] have been also reported.

Acidic iron electroplating baths are well studied;

they are highly productive and relatively simple as concerns their composition.

Nevertheless, acidic electrolytes for iron electrodeposition are rather

corrosive and toxic; therefore, development of novel acidic Fe(II) baths is an

important problem of modern electroplating.

Aqueous solutions of Fe(II) on the base of

methanesulfonic acid (MSA) seems to be an attractive and perspective

alternative to common iron electroplating baths as MSA is considered as a

"green acid" due to its environmental advantages [7]. MSA is known to

be far less corrosive and toxic than the usual minerals acids used in different

branches of industry. Methanesulfonate of various metals are highly soluble in water, the conductivity

of corresponding aqueous solutions is high. In addition, MSA is easily

biodegradable. Because of these advantages, electrochemical systems on the base

of MSA and its salts have been shown to be very promising for electroplating of different

metals and alloys [8-19].

Nonetheless, there are only several papers devoted to electrodeposition of

iron from methanesulfonate bath [20-22]. Thus, this question remains practically

unexplored. This communication is devoted to brief description of results of

our preliminary experiments relating to the problem involved, iron

electrodeposition from methanesulfonate electrolyte being compared with that

from "usual" sulfate electrolyte.

We have stated

that the deposition of iron is advisably to perform in the electrolytes containing

1.25 mol/dm3 Fe(CH3SO3)2 or 1.25

mol/dm3 FeSO4. There is no need to add some buffer or

conductive additives as well as surfactants to the baths.

The

optimal electrolyte pH seems to be in the range from 1.2 to 1.8. At lower pH

values (<1.2), the current efficiency of iron deposition decreases

dramatically due to the fact that hydrogen evolution reaction accelerates. At

higher pH values (>1.8), the rate of the chemical redox reaction between

dissolved oxygen and Fe(II) ions increases, and the latter process is highly

undesirable because the quality of deposits obtained deteriorates substantially.

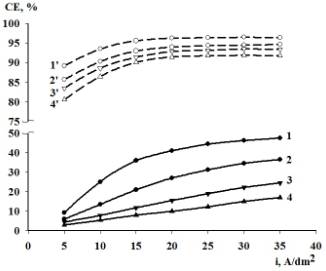

As can be seen

in Figure 1, an increase in the current density results in an increase in the

current efficiency both in a sulfate bath and in a methanesulfonate one. For

the case of methanesulfonate electrolyte, current efficiency grows if the

current does not exceed 25 A/dm2, and then remains practically

constant. An increase in the bath temperature leads to a decrease in the

current efficiency at all employed current densities, this dependence being

more pronounced in case of sulfate electrolyte.

Figure 1.

Effect of current density on the current efficiency of iron deposition at bath

temperature (K): (1, 1Т) Ц 298; (2, 2Т) Ц 308; (3, 3Т) Ц 318; (4, 4Т) Ц 328.

Bath

composition: (1, 2, 3, 4) Ц1.25 mol/dm3 FeSO4; (1Т, 2Т,

3Т, 4Т) Ц 1.25 mol/dm3 Fe(CH3SO3)2;

pH 1.3

It should be

observed that the values of current efficiency in methanesulfonate

electrolyte are sufficiently larger than those in sulfate electrolyte, all

other conditions being kept identical. Such a feature is an essential advantage

of the methanesulfonate bath for iron electrodeposition in comparison with that

on the base of sulfate salts.

In

addition, the nature of anions exercises a significant influence upon the

surface appearance of the Fe coatings. Matt coatings deposits from sulfate bath

whereas bright deposits are obtained from methanesulfonate system.

It should be noted

that quite high values of current densities may be achieved in methanesulfonate

iron bath under consideration.

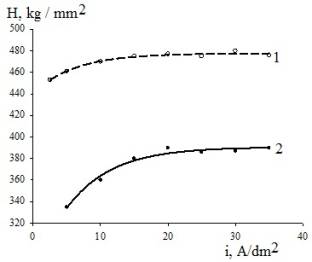

Microhardness

belongs to the most important properties of iron electrodeposits. As is shown

in Figure 2, the quantities of microhardness of coatings obtained from

methanesulfonate bath are greater than those in case of sulfate bath.

Figure 2.

Effect of current density on the microhardness of iron deposits (bath

temperature 298 K, pH 1.3)

Bath

composition: (1) Ц 1.25 mol/dm3 Fe(CH3SO3)2;

(2) Ц1.25 mol/dm3 FeSO4

Thus, methanesulfonate electrochemical systems for iron

electrodeposition seem to be highly attractive for practical use; they require

further comprehensive investigations.

References:

1. Y. Fujiwara, T. Nagayama, A. Nakae, M. Izaki, H. Enomoto, E.

Yamauchi, J. Electrochem. Soc. 143 (1996) 2584.

2. M. Panayotova, Surf. Coat. Technol. 124

(2000) 266.

3. A. Bai, C.-C. Hu, T.-C. Wen, Electrochim.

Acta 48 (2003) 2425.

4. F. Lallemand, L. Ricq, M. Wery, P. Berçot,

J. Pagetti, Appl. Surf. Sci. 228 (2004) 326.

5. N. Miyamoto, K. Yoshida, M. Matsuoka, J.

Tamaki, J. Electrochem. Soc. 151 (2004) C645.

6. F.I. Danilov, V.S. Protsenko, A.V. Ubiikon', Russ. J. Electrochem. 41 (2005)

1282.

7. M.D. Gernon, M. Wu, T. Buszta, P. Janney, Green Chem. 1 (1999) 127.

8. F.I. Danilov, I.V. Sknar, Yu.E. Sknar, Russ. J. Electrochem. 47 (2011)

1035.

9. N. M. Martyak, R. Seefeldt, Electrochim. Acta 49 (2004) 4303.

10. C.T.J. Low, F.C. Walsh, Electrochim. Acta 53 (2008) 5280.

11. C.T.J. Low, F.C. Walsh, Surf. Coat. Technol.

202 (2008) 1339.

12. H. Wang, M.

Pritzker, Electrochim. Acta 53 (2008) 2430.

13. C.S. Chen, C.C.

Wan, Y.Y. Wang, Trans. Inst. Metal Finish. 76 (2) (1998) 54.

14. F.I. Danilov, T.E. Butyrina, V.S. Protsenko, E.A. Vasil'eva, Russ. J. Appl. Chem. 83 (2010)

752.

15. F.I. Danilov, E.A. Vasil'eva, T.E. Butyrina, V.S. Protsenko, Prot. Met.

Phys. Chem. Surf. 46 (2010) 697.

16. F.I. Danilov, V.S. Protsenko, E.A. Vasil'eva, O.S. Kabat, Trans.

Inst. Metal Finish. 89 (3) (2011) 151.

17. G. Saravanan, S. Mohan, R.M. Gnanamuthu, J.

Vijayakumar, Surf. Eng. 24 (2008) 458.

18. S. Mohan, J. Vijayakumar, G. Saravanan, Surf. Eng. 25 (2009) 570.

19. V.S. Protsenko, A.A. Kityk, F.I. Danilov, J. Electroanal. Chem. 661

(2011) 213.

20. S.P. Sidelnikova, Yu.N. Petrov, Yu.S. Gorodetskii, Zashch. Met. 10 (1974) 187.

21. E.D. Pleshka, Surf. Eng.

Appl. Electrochem. 44 (2008) 92.

22. E.D. Pleshka, Surf. Eng.

Appl. Electrochem. 44 (2008) 264.