Lukuttsova N.P, Pykin

A.A., Pustovgar A.P.

Bryansk State Academy of

Engineering and Technology, Bryansk, Russia

Physical and mechanical properties of

fine-grained concrete with admixture nanodispersed schungite

Physical and mechanical properties of fine-grained

concrete modified by nanodispersed admixture such as water suspension of

schungite (Karelia, Russia) are investigated. Schungite is a natural petrified

organic silica gel with 51-67% silica dioxide and carbon 28-32%. Admixture was

obtained by ultrasonic dispersion reduced to powder

schungite in water in the presence of the stabilizer.

Nowdays in Russia and abroad the urgent task of

nanotechnology in concstruction industry is to discover cheap and efficient

methods of obtaining nanomodifying admixtures which make it possible, at

nano-and microlevels, to control the

processes of structure formation of composite materials and concrete among

them.

Promising scientific and technical area is the

accumulation of knowledge and experience in cavitation technology. Examples of

practical application of these technologies is obtaining nanoparticles in

exploding cavitation bubbles, hyperfine dispersion of organic and inorganic

materials in liquid media, ultra-fine aerosols for the needs of nanoelectronics

and chemical industry, coating, obtaining nanosuspensions and nanoemulsions,

compacting nanopowders, cleaning and so on.

The

aim of this work is to investigate the dependence of the particle diameter of

schungite water suspensions on the time of ultrasound and the presence of the

stabilizer and as well as to study the effect of the suspension on physical and

mechanical properties of fine-grained concrete (FGC).

A characteristic feature of schungite is the

structure of its carbon, which is the globule size from 6 to 10 nm. Scientists

have determined the morphological similarity of schungite carbon globules and

fullerenes: presence of an inner cavity and a two-dimensional hexagonal cell of

carbon atoms. The carbon part of sñhungite

is described by formula: C690-2300H100N5-14O5-16S1-12.

The

specificity of schungite structure is also in the fact that silicon dioxide and

carbon form a strong interpenetrating nets. Therefore, each particle of

schungite powder contains a nonpolar carbon and polar mineral components.

Schungite

make it possible to produce electroconducting construction materials on its

basis (mechanical strength, abrasion resistance, freeze-thaw resistance, electrical

conduction, corrosion stability).

Besides,

the unique features of schungite are used to create on its basis structural

radio waves shielding materials [1].

In

order to obtain schungite powder with a

specific surface of particles 320-350 m2/kg grinding of schungite

gravel fraction 3-10 mm was being conducted for 1 h in a vibratory mill. The

particle size of schungite powder was being determined by method of laser

granulometry with «MicroSizer 201».

Then, the schungite powder was added to water in the amount of 1% and

treated by ultrasonic at frequency of 22 kHz from 15 till 30 minutes. The same

was done with schungite powder which particles surface was treated with

molecules of stabilizer of naphthalene-formaldehyde type (NF) at combined dry

grinding of schungite and NF composition 1:0.5.

The size of the particlesobtained after USD suspension was determined

with the help of a multilevel system 90Plus/Bi-MAS. This system designed to

determine the particle size of concentrated suspensions of macromolecules.

To study the effect of nanodispersed schungite on mass specific gravity,

water absorption, ultimate compressive strength and initial modulus of

deformations of fine-grained concrete test beams of 4×4×16 cm size

were produced. They were made of portland cement M 500 R0 and quartz sand with

fineness modulus 1.5 composition of 1:3. Supplements were admixtures in the

amount of 1% from cement mass with water. These test beams were hardened under

normal conditions.

To determine the initial modulus of deformation of test fine-grained

concrete were modified by microdispersed schungite at 5% from cement mass and

subjected to static and dynamic loads.

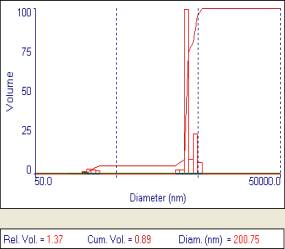

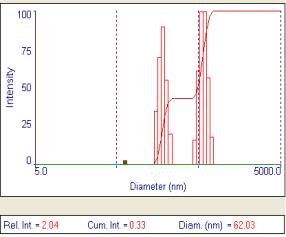

Figure 1 shows that the optimum time of ultrasonic dispersion of

schungite powder in water without stabilizers is 15 minutes. It helps to obtain

a suspension with particle from 201 to 5112 nm.

Figure 1. Histogram of schungite particles distribution according to their sizes

after

the

USD in water during 15 minutes

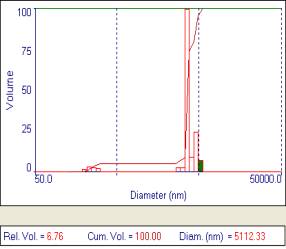

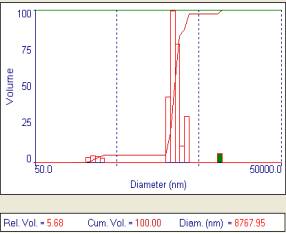

An increase in the USD up to 30 minutes leads to

particle aggregation and formation of more coarse suspensions with particle size ranges from 220.82 to 8767.95 nm (Figure 2).

Figure 2. Histogram of schungite particles distribution according to their sizes

after

the USD in water during 30

minutes

Aqueous suspensions of schungite are

kinetic polydisperse and unstable regardless of the time of ultrasonic

treatment. Sedimentation of aggregated particles is observed after 1-2 hours [2].

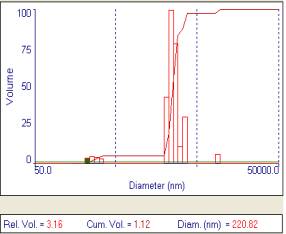

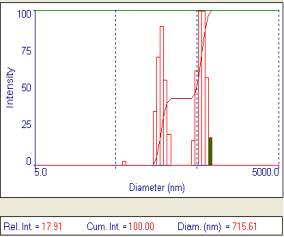

The smallest diameter of schungite particles

in water suspension, the absence of their aggregation and sedimentation are

observed in the dry depositing of molecules of the stabilizer of naphthalene-formaldehyde

type on the surface of schungite particles under the combined grinding components

according to USD. Ultrasonic dispersion of such particles during 15 minutes

helps to obtain a suspension with a particle diameter from 62 to 716 nm (Figure

3).

Figure 3. Histogram of schungite particles distribution according to their sizes

after

the USD in water

during 15 minutes in the presence of NF stabilizer

FGC

maximum strength is observed with the introduction of the suspension of

nanodispersed schungite suspension, which is stabilized by dry deposition NF

stabilizer on the surface of schungite particles before ultrasonic dispersion

(Table 1).

According to the table 1 maximum strength of modified concrete exceeds

the strength of the control composition in 2.8 times after 3 days and 2.1 times

after 28 days of hardening.

The results showed an increase in mass

specific gravity from 1760 to 2242 kg/m3 and a decrease

of water absorption from 2.4 to 0.9% in the strength of fine-grained concrete

with nanodispersed schungite admixture.

When introducing in FGC microdispersed schungite in the amount of 5% an

increase in initial dynamic modulus of the strain up to 45% takes place [3]. It

is especially important in the construction of buildings and structures in the

areas of high seismic activity.

Table 1. Physical and mechanical properties of fine-grained concrete modified by

suspensions

nanodispersed schungite

|

¹ |

Composition of the

FGC, the dispersion of admixture, the presence of the stabilizer |

C/W |

Mass specific grayity,

kg/m3 |

Absorption of water,

% |

Ultimate compression

strength MPa, after days of hardening |

||

|

3 |

7 |

28 |

|||||

|

1 |

FGC control |

0.43 |

1960 |

2.4 |

9.2 |

16.4 |

23.8 |

|

2 |

FGC with 1% schungite 201-5112 nm without stabilizer |

0.43 |

2085 |

1.9 |

12.1 |

19.9 |

34.0 |

|

3 |

FGC with 1% schungite 62-716 nm with stabilizer NF |

0.43 |

2242 |

0.9 |

25.7 |

33.0 |

50.0 |

A

positive impact of nanodispersed schungite on the strength and deformation

properties of fine-grained concrete was determined. This method is

characterized by high productivity and easy hardware.

The

composition of the modified fine-grained concrete with nanodispersed schungite

stabilizer in the presence of NF is recommended for covering the extra strong

floors, construction elements of the urban slum (curbing, paving flag, etc.),

as well as structures and constructions, resistant to bending loads.

References:

1. Sokolov V.A., Kalinin Y.K.,

Dyukkiev E.F., Schungite – the new carbon materials, Petrozavodsk, 1984 (in

Russian).

2. Lukuttsova N.P., Pykin A.A., Chudakova O.A. Modification of fine-grained

concrete with micro-and nanosize particles of titanium dioxide and schungite, Journal BSTU V. Shuhov, pp. 73-76,

Belgorod, 2010 (in Russian).

3. Shablinsky G.E., Lukuttsova N.P., Pykin A.A., Tsvetkov K.A. Investigation

of dynamic strength and rigidity of products from fine-grained concrete

modified by nanostuctured schungite aggregate, Journal MSSU, pp. 231-236, Moscow, 2010 (in Russian).