Lukuttsova N.P,Chudakova

O.A., Pustovgar A.P.

Bryansk

State Academy of Engineering and Technology, Bryansk, Russia

Decorative

compositions based on nanodispersed titanium dioxide

Studied by an

ultrasonic method for producing stable suspensions of nanoparticles of titanium

dioxide, studied the strength characteristics of decorative and finishing

compositions based on gypsum and cement binders with nanodispersed additive.

Nanoparticles react with the basic chemical elements of mortars, act as

crystallization centers. There is a decrease of porosity, thereby improving

physical and technical properties of building compositions.

From the quality

finish of buildings and interiors for new construction or reconstruction depend

not only on their aesthetic, but also the operating parameters as well as

High-quality finish - a guarantee of long-lived basic service structures,

long-term maintenance-free operation, minimal maintenance costs and maintenance

[1].

The solution to

this problem can be achieved in the first place, by modifying the structure of fine-grained concrete used for decorative

compositions and mortars, improve the quality of the joint work of all

components. One of the promising research directions to improve the quality of building

composites are sales in their production of nanotechnology.

To date,

construction materials, containing added TiO2-nanoparticles are widely used in

paints, special cements, mortars, self-cleaning ceramic tiles, road surfaces,

like concrete and asphalt, self-cleaning materials and designs,

vozduhoochischayuschih materials and structures, and antibacterial materials

structures, compositions and decoration materials for interior and exterior,

etc. [2].

Especially common

use of such light-sensitive catalysts in the formation of self-cleaning

surfaces by the recently discovered phenomenon supergidrofilnosti, thus

maintaining the aesthetic appearance of the constructed objects unchanged for a

long time [3].

The aim of the

research work was to obtain nanoparticles of titanium dioxide under ultrasonic

treatment, the study of the influence of the suspension on the strength

characteristics of building compositions based on gypsum and cement binders.

In the experiment

we used the following materials: portlandcement M 500 A0 OAO Mal'tsovsky

Portlandcement, gypsum binder grade G-4, alluvial sand (II) Module size 1.6 (

Sven, Bryansk region), cement-water ratio =0.43.

As an additive

used in a concentrated suspension of nanoparticles of titanium dioxide.

Nanoparticles of

titanium dioxide prepared under ultrasonic dispersion (USD) of pigment powder

particle size of 30 microns, which is due to cavitation and the mutual friction

of rapidly moving and colliding particles in two phases.

In the first

phase (flowing within a few tens of seconds), grinding is due to the presence

of the original particles of a large number of micro cracks and, therefore, the

friction of the fluid particles and their mutual collisions play a dominant

role.

In the second

phase of the grinding is due to cavitation shock waves forming new cracks in

the particles [4].

Optimum time

ultrasonography, provides for the receipt of minimum particle size corresponded

to 10 minutes.

To obtain stable

suspensions of nanoparticles of titanium dioxide as a stabilizing medium used

organic rastvoroitel.

The particle size

of suspensions after the USD was determined using a multilevel system

90Plus/Bi-MAS.MAS-OPTION to determine the particle size of concentrated

suspensions or macromolecules.

Found that

ultrasonic treatment promotes the refinement of the particles of titanium

dioxide in an organic solvent the Figure 1.

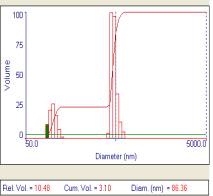

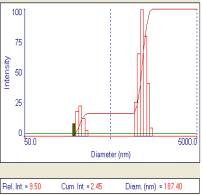

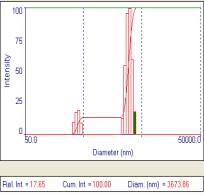

à) b) c)

Figure 1 - Histograms of

the distribution of the particles of titanium dioxide in size

after the USD in an organic

solvent:

a)

the minimum size of particles;

b) the average particle size;

c) maximum particle size

Figure 1 shows the histogram distribution of the particles of titanium

dioxide in size after the USD in an organic solvent. The minimum particle size

is 86.36 nm with a polydispersity of 31.7%, the average size of 187.40 nm

without changing the polydispersity and the maximum size corresponds to 3673.86

nm with a slight increase of polydispersity of up to 32,9%.

The composition suspension was introduced with a minimum diameter of the

particles in an amount of 0,1 - 1% by weight of binder.

The

strength of the samples - the size of cross members 40h40h160 cm was determined

after 28 days uncured for building composites based on cement binder. The

results are shown in Table 1.

As

the table shows, the strength of the samples with the addition of titanium

dioxide nanodispersed exceeds the strength of the control structure.

The

best indicator of bending strength corresponds to 0.1% injected additives, compression

- 0,25. In this case, bending strength increases by 2,5 times, compression 1,5.

Table 1. Bending strength

and compression of mortars based on cement binder

modified with the addition of

titanium dioxide nanodispersed

|

¹ |

Number of additives, % |

Flexural strength after 28 days of hardening, MPa |

Ultimate

compression strength through 28 days of hardening, MPa |

|

1 |

0 |

3,3 |

33 |

|

2 |

0,1 |

8,4 |

43,8 |

|

3 |

0,25 |

7,2 |

46 |

|

4 |

0,5 |

5,3 |

37 |

|

5 |

1 |

6 |

35,6 |

Established that the introduction of the suspension in the mortar in the

amount of 0,5 - 1% and increases the tensile strength in bending in 1,6 - 1,8

times, and compression in 1,2 - 1,1 times.

For building composites based

on gypsum binders ultimate strength were determined after 2 hours uncured. The

data are shown in Figure 2.

Figure 2 - Flexural

strength and compression strength of mortars based on

gypsum

binder modified with the addition of titanium dioxide

nanodispersed

Established that the bending strength is reduced from 2.3 MPa to 1.88

MPa, while compressive strength increases from 4.58 MPa to 5.44 - 19 %.

Thus, TiO2 - versatile material that can be used not only as a white

pigment, but nanodispersed additive that improves the strength characteristics

of the decorative composites.

The developed additive improves the properties of the construction and

maintenance solutions as the plaster and the cement binder and is recommended

for use in the construction industry.

According to the results of work it was found that brand gypsum binder

for the additive increases with the F-4 to F-5, which reduces the creep gypsum

solution.

The obtained building compositions based on cementitious binders

appropriate to apply, for example, to fill the high-strength, abrasion-resistant

floors, as well as for making structures working in bending.

References:

1.Finishing composition

based on liquid glass [Text] / G. Yakovlev, A. Pislegina, J. Keren, A. Weeds //

Building Materials, Equipment, Technologies of XXI veka.-2009 .- P. 10-12.

2.Chudakova, O. Effect of

nano-sized particles of titanium dioxide on the strength characteristics of

mortar / O Chudakova / Youth and scientific and technological progress: The

Gathering. works, Issue I. - Bryansk: BGITA, 2010 .- S. 207-210.

3. Falikman, WR On the use

of nanotechnology and nanomaterials in construction. Part 1 [Text] / VR

Falikman / Nanotechnology in Construction: Scient. Internet Journal .- 2009 .-

¹ 1 .- S. 24-34.

4.Tolochko, NK, constable,

PG, Zhdanok SA, Krauklis AV Ultrasonic dispersion of carbon nanomaterials

[Text] / NK Tolochko, PG Constable, SA Zhdanok, AV Krauklis / / Advanced

Materials .- 2008 .- ¹ 2 .- P. 5-9.