Lukuttsova N., Matveeva

E., Pustovgar A.

Bryansk State Academy of

Engineering and Technology, Bryansk, Russia

Nanomodified fine-graned concrete

The purpose

of the given work is the research of the additive "NANO-F" containing

stabilised nanosilica and its influence on structural and strengthening

characteristics of fine-grained concrete (FGC).

The term

“nanodispersed silica” combines diverse varieties of dispersed silica (sols,

gels, suspensions, pastes) found naturally (quartz, opal, chalcedony), or created

by man in the process of technological activity (Aerosil, hydrosols).

Nanodispersed silica is an important natural feature and the main component of

the oxide materials obtained by sol-gel method. The most interesting and

important representatives of nanodispersed silica are sols (dispersed systems

with liquid dispersive medium and solid

disperse phase), which particles are involved in Brownian motion.

This work

resulted in obtaining the additive "NANO-F" and the research on how

the age of additive influences the strengthening characteristics of FGC on

Portland cement M 500 D0, produced at JSC op. “Maltsovsky Portlandcement”,

quarts sand MK = 1,2 and cement-water ratio = 0,38 was carried out. Researches on dispersion processes and

aggregation of silica particles due to different age of the additive were

conducted. The nanostructure additive in the amount of 10% was input with a

solution of a stabilizer into a concrete mixture, where the content of

nanoparticles of silica makes 0.23 %.

The regulation of a concrete mixture mobility was performed with

supersoftener Ñ-3 in the

amount of 1 % from cement mass.

The size of

silica paticles in the developed additive was determined with foton-correlation

spectroscopy (PCS) of quasielastic scattered

light (QELS) by means of multiangular system for determining particles

sizes 90 Plus/ Bi-MAS. MAS-OPTION is an automatic system for fixing sizes

particles of used either for concentrated suspensions of small particles or for

the sizes of marcoparticles. Raster ionic-electronic microscope Quanta 200 3D

was used for studying microstructure. The X-ray-analysis was conducted on

diffractometer ARL X’TRA of the firm Thermo Scientific (Switzerland); the

thermal analysis with thermoanalyzer SETARAM LABSYS – by methods of TGA and DSC

at t=600ºÑ and heating

speed of 10˚/min; researches of samples porosity - by means of mercury

AutoPore IV 9500, which make it possible to measure pores in diameter in a

range from 0.0055 to 360 microns.

Additive

synthesizing was carried out by a chemical method of polycondensation [1]. Silicic acid sol is a noncrystalline

condensation nanodisperse structure from metastable solutions. Silicic sol is

characterised by aggregative instability at the change of temperature [2].

To find out

changes of nanosilica particles size in the developed additive due to their

aggregation in course of time they were examined at the of 1, 3, 5, 7,10 and 14

days.

Dependence

of ultimate compressions strength influence of FGC on nanosilica content in the

additive at the age from 1 till 14 days is given in Table 1.

Table 1 Ultimate

compression strength of fine-grained concrete depending on the nanosilica

particles content

|

¹ |

Composition of the FGC |

Ultimate

compression strength after 28 days of hardening, MPa |

The content of nanosilica particles size 20-100 nm, % |

|

1 |

Control

composition |

29 |

- |

|

2 |

FGC+ sol aged 1 day |

54 |

6 |

|

3 |

FGG + sol aged 3 days |

58 |

94 |

|

4 |

FGG + sol aged 5 days |

59 |

92 |

|

5 |

FGG + sol aged 7 days |

56 |

94 |

|

6 |

FGG + sol aged 10 days |

57 |

90 |

|

7 |

FGG + sol aged 14 days |

56 |

56 |

|

8 |

FGG+sol aged 4months |

- |

18 |

As we see

from the Table 1, the nanosilica content in the additive after 3 days increases

from 6 to 94 %, and after 14 days decreases to 56 %. The maximum value of FGC

compression strength is reached while using silicic sol at the age from 3 till

14 days, it is in 2 times exceeds the value of ultimate compression strength of

test samples.

Increase in

strength of FGC is also caused in our opinion due to the presence of

stabilizing agents- the acetates-ions preventing the aggregation of silica

particles. In the interaction of calcium hydroxide with sodium acetate calcium acetate is formed [5]. According to

[3], calcium acetates and others calcium salts refers to a group of the

additives, joining with the binder in addition reactions forming almost

insoluble mixed salts - hydrates. Calcium acetate, in its turn, interacts with

major cement clinker minerals to form almost insoluble mixed calcium salts.

At the initial stage of hydration

crystallization speed of mixed

insoluble calcium salts are above the speed of ettringite formation.

Crystals of these formations have microreinforcing effect on a cement stone

raising its density. Nanosilicaparticles in

combination with forming insoluble calcium salts directly participate in formation of cement

stone structure, being built in hydrates structure and filling a pores, and,

thereby, raising density of concrete [3]. It also leads to formation of a

primary skeleton, which provides the

process of increasing strength of a cement stone at early stages of hardening.

Nanosilica directly participate in the process of structure formation of a

cement stone.

Gradual

formation of ettringite additionally microreinforces the structure of a cement

stone. Calcium hydrosilicates differ in uniform submicrocrystalline structure,

that also helps to increase strength [4]. At the age of 14 days in samples with

nanosilica recrystallization of ettringite in monohydrosulfaluminate is

excluded, because of Ñ3À deficiency

in the system, caused by its linkage into insoluble calcium salts.

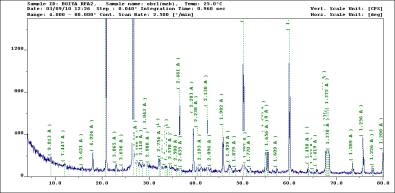

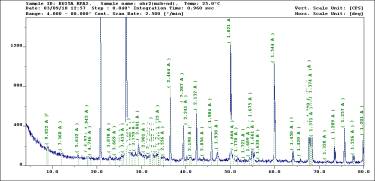

To study the

character of influence of developed additive "NANO-F" on the

formation feature of FGC structure X-ray and the thermal analysis of samples

were carried out (Figures 1,2).

As a result

of the conducted qualitative and quantitative phase analysis according to

Ritveld’s method 14% decrease in intensity of the portlantide reflexion in

modified samples (4.91 ; 2.63; 2.75; 2.70 Å), 8% intensity increase of

ettringite reflexion (9.81; 3.86; 2.57;

5.62 Å) 18% increase of CSH reflexion (12.6; 11.84; 10.2; 3.07 Å),

in comparison with the control sample in which as opposed to modified one the

reflexion of monohydrosulfaluminate (8.93 Å) is fixed, it indicates the partial recrystallization of ettringite.

It is known,

that for Ñà (OH) 2

the friable structure which is a slaty hexagonal lattice constructed of

three-layer packages is typical. It is typical for Ca (OH)2 to have

large tetrahedronic cavities, into which not only atoms Si can get (to 25 % of

lump SiO2), but also larger ions Àl, Fe. At the same time firm

compounds in which the atom of one element (Si) does not replace completely

atoms Ñà are formed

and located in intervals between them in free cavities. Atoms Si introduced

into structure change the position of atoms of oxygen which results in

enlargements of peaks Ñà (OH)2 that

is observed in the XRD of the modified sample.

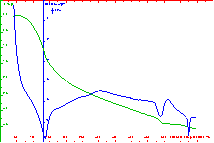

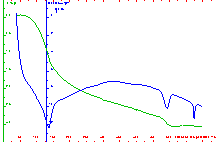

The thermal

analysis spent in common by methods DSC and ÒGA shows that for the received

curves general laws are typical at heating. (Figure 3). In the range of temperatures 475 - 500 °Ñ on the

curve ÒGA the

second step of weight loss is observed , on the curve DSK - corresponding to it

endothermal effect with a maximum is observed at temperature 486°Ñ. That

corresponds to the loss of crystal waters by compounds 3CaO·SiO2,

2CaO·SiO2 of a cement stone.

Figure 1. X-ray-analysis of FGC control simple

Figure 2. X-ray-analysis of modified sample

For all

samples there is a strongly pronounced endothermal effect with a maximum at

temperature 575°Ñ. At integration

of peaks, typical for Ñà (OH)2,

on curves TGA and DSC insignificant decrease in thermal effect on 14 %, and

also weight losses - on 25 % for the modified sample in comparison with control

one was revealed.

At the same

time it is necessary to notice, that at complex use of the additive and

supersoftener Ñ-3 the

formation of more dense structure of FGC, as well as the decrease in its

defectiveness (Figure 4) is observed.

With the

introduction of modifying additives in fine-grained concrete total pore volume

decreases from 0.0849 to 0,0687 mg/l, and average pore diameter - on 3.2

microns to 0.83 microns.

Thus, the

results of this research can draw the following conclusions.

1.

The sizes of nanosilica particles of

investigated additive depend on its age and vary from 30 nm to 540 nm, and the

content of particles 20-100 nm in size from 3 to 10 days is 90 ... 94%, so it is most effectively to

use it during this period

2.

Integrated use of modifying agent and

supersoftener Ñ-3 in FGC results not only in modification of the structure of cement stone by nanosilica,

but also in the formation of insoluble mixed salts which fill the pores of

fine-grained concrete. It helps to decrease the average diameter of pores from

3.2 to 0.83 microns and to redistribute pores according to their sizes towards

their reduction and also provide the

improvement of structural and strengthening parametres of FGC – obtaining

of samples with compression strength, in 2 times exceeding the value of ultimate compression strength

of control samples.

a b

Figure 3. TGA and DSC curves of: a- control sample,

and b- modified sample

.

a b

Figure 4. Microstuñture of FGC samples: a- control

samples, b- the modified samples.

References:

1.

N.Shabanova,

P.D.Sarkisov, Sol-gel technology of nanosilica, Moscow, 2004 (in

Russian).

2.

Yu. Frolov, Silicic acids: obtaining and

application of silica hydrosols, Moscow ,1979 (in Russian).

3.

V. Ratinov, T.Rosenberg. Additives in concrete, Moscow,

1989 (in Russian).

4.

P.Sadykov, Z. Estemesov, B. Dusipov, Features of hydration of the

cements containing dispersive polymeric powders. Journal: Technologies of

concrete, pp.68-69, Moscow, 2008 (in Russian).

5.

N. Lukuttsova, E. Matveeva, Nanomodified

fine-grained concrete. N 3 Scientific and technical Journal MSSU,

pp.84-102, Moscow, 2009 (in Russian).