Badanova A.K., Badanov K.I.

Taraz state university named

after M.Kh. Dulaty, Taraz

INTENSIFICATION OF PROCESSES OF

DYEING AND PRINTING OF TEXTILE MATERIALS FOR DECREASE OF DUMPS IN WASTEWATER OF

THE DYEING-FINISHING ENTERPRISES

The

wastewater of dyeing-finishing manufactures of a textile industry is subdivided

into three basic kinds:

- Industrial, i.e. wastewater

after realization of the basic technological processes and waters acting from

processes of auxiliary manufactures (a chemistry station, a dye-boiler, a boiler-house

etc.);

- Household, i.e. wastewater

of shower and sanitary rooms, restaurants etc.;

- Atmospheric, i.e.

rain water and water of thawing snow.

The

industrial wastewater makes up the bulk part of the enterprise drains. The

quantity and the structure of wastewater change depending on the kind of

manufacture, assortment and output, dyeing-finishing equipment. For the

concrete enterprise the volume and the structure of wastewater may vary

considerably during the day. These changes are estimated using the coefficient of

hour non-uniformity. The coefficients of hour non-uniformity of a total drain

of the cotton enterprises usually change from 1.5 up to 1.75. For the woolen

enterprises the coefficients of hour non-uniformity reach up to 3.9.

Dueing-finishing

manufactures of the cotton industry are water-intensive manufactures. The norm

of wastewater in the cotton-printing factory is 200 m3 per 1 ton of output.

In drains there are 120 kg/t of fabric the mineral and 60 kg/t of fabric the organic

impurities, 7 kg/t of fabric the synthetic SAS, 8 kg/t of fabric the finishing

preparations, 2-3 kg/t of fabric the dyes [1].

The wastewater

of dyeing-finishing manufacture differs with significant non-uniformity of

inflow and concentration of pollution. It contains all of the substances used

in the modern technological processes: bleaches, dyes of different classes, thickening

agents, reducing agents, dressing substances, catalysts, softeners, textile-auxiliary

substances, equalizers, washing-up liquids, etc.

At dyeing

and printing of cotton fabrics the basic part of pollution of wastewater is

made by the unfixed dyes. Depending on the nature of dye and used technology

their allotment varies from 10 up to 40 %. In the periodic methods the

significant portion of dyes remains in a dyeing bath. After the appropriate

reinforcement the solution in the dyeing bath can be used for 4-5 times and

only after that it would be dumped either on factory clearing structures or in

the municipal sewerage system. At continuous ways of dyeing the wastewater is

formed from washing a textile material. In addition to the dyes in wastewater

the different textile-auxiliary substances (SAS, oxidizers, reducing agents,

electrolytes etc.) and fixators of colouring get also. So, for example, at use

for fastening preparations DCA, DCC, steady - 2 on the equipment of periodic

action in wastewater 50 % of the specified substances depart, and on the equipment

of continuous action - 25 %. In case of useing active dyes in wastewater 20-40

% (from the initial amount) of dye, electrolyte, SAS and urea gets. Urea, being

dumped with drains in reservoirs, promotes increase the nitrate content. Application

of sulphury dyes results in presence of sulphides in wastewater of dyeing shop.

The volume of wastewater from sulphury dyeing in modern dyeing-finishing

manufactures of the cotton enterprises is 3-4 % of the total amount of wastewater.

After printing the drains are formed at the stage of washing of the textile

material after fixation of dyes. Besides dyes and textile-auxiliary substances wastewater

of printing shops contains thickeners. The thickeners are natural or synthetic

polymers requiring additional oxygen consumption for oxidation during clearing.

Dyeing station in printing shop causes additional loading on the environment. In

the dyeing station wastewater is formed from washing various capacities. In wastewater

from printing shop the rests of dyes and textile-auxiliary substances get also

from washing tarpaulin in tarpaulin washing installations of printing machines,

"the black lining" in washing machines WM - 200 after drawing figure

and processing in ripe station.

For

knitted fabrics the questions about dyeing and printing are especially urgent.

The structure of stockinet is very sensitive to different mechanical

influences, including on the part of working bodies of finishing machines. The

search of new methods of drawing dyes on knitted cloths with the minimal

mechanical action and decrease of dumps in wastewater is the important

scientific and technical task.

Printing

of knitted fabrics using ultraviolet rays (UV-rays) can be attributed to

nonconventional ways of printing. At using ultraviolet rays there is no

traditional way of preparation a printing paint and traditional drawing it on a

stockinet. When using UV-radiation the solution of dye prepares instead of

printing paint. The solution consists of 2-3 components, and the printing ink

consists of 7-9 components, and in the printing ink there is a thickener necessarily

[2].

In TarSU

named after M.Kh. Dulaty at the Department of The technology of

textile production the experiments were

carried out for printing figures on knitted cloths with coubozol gold-yellow

and coubozol dark blue. For each dye it is necessary individually to pick up

time of the irradiation, height of an arrangement of the irradiation source,

optimum concentration of dye, etc. In the experiments we use the device [3] and

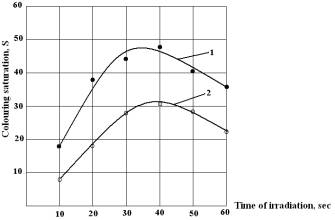

determine the optimum parameters of UV-processing for knitted cotton cloths. In

the fig. 1 there is shown the influence of irradiation time on the colour saturation

of the cotton knitted cloth impregnated with solutions of coubozol dark blue

and coubozol gold-yellow YCh.

Fig. 1.

Influence of irradiation time on colour saturation of the cotton fabric impregnated

with solutions of coubozol dark blue (1) and coubozol gold-yellow YCh (2)

Optimum

time of irradiation for dark blue coubozol and golden-yellow coubozol is 30 seconds. It was established that at

use of UV-irradiation the initial background changes unsignificantly: 1.85 %

against 2.7 % in the classical method. At use of UV-irradiation the stability

of figures’ colouring was 5 points,

and on the classical way it was 4-5 points. Color saturation of printed images is

above at using UV-irradiation. The use of UV-radiation excludes blur of figures

contours. When printing by the classical way the quality of preparation of thickener

and printing paint influences on quality of printing. Use of UV-irradiation

allows completely to exclude a printing paint. The printing paint is replaced by solution of two or three components. The UV-radiation

allows to show and to fix colouring only in the impregnated places with the

established patterns on the surface of a cloth. Therefore, the charge of

chemical materials is reduced. The processing in the solution of the oxidizer

is excluded. The technological time for drawing the figure is decreased. The

comparative characteristics of ways of printing a cotton knitted cloth with

coubozol dark blue is shown in the Table 1.

Table 1.

The comparative characteristics of ways of printing with coubozol dark blue

|

Method of printing of cotton

knitted fabrics |

|

|

Classical: Printing paint, g/kg |

Offered: Solution with using UV-irradiation, g/l |

|

1. Tragent

thickener 628 2. Coubozol 30 3. Glycerin 15 4. NaNO3 15 5. Na2CO3 2 6. H2O

hot 300 7. Develop

solution: H2SO4

(r=1,84 g/sm3) – 20ml/l + +urea 5 g/l 8. SAS (for

soaping) 5 g/l |

1. Coubozol 6 2. Sopal 0.3 3. NaCI 12 4. SAS (for

soaping) 5 |

|

Print mode |

|

|

Printing ® Drying at 70îÑ, t=20 min ® Development

t=20 sec ® Processing with cold and

hot water ®

Soaping 5g/l ® Washing

with hot and cold water. |

Impregnation at

40îÑ, t=5 min ® UV-processing

t=30 sec ® Soaping 5g/l ® Washing with

hot and cold water. |

The

carried out researches allow to assume that the UV-radiation can be used for

printing figures, ornamental patterns on knitted cloths. Use of UV-irradiation

will allow to apply colouring and figures on textile materials on international

standards ICE. It considerably will cut down expenses of dyes and textile-auxiliary

substances and also will allow to reduce emission of chemicals in wastewater.

References

1. Sadova S.F., Krivtsova G.E., Konovalova M.V. Ecological problems of

finishing manufacture. /Textbook for high schools edited by Sadova S.F./ - M.:

EPD of MSTU, 2002. – 284 p.

2. Badanov K.I. Prospects for the use of UV-radiation for finishing of

fulling-felt products. STIC "Ëåãïðîì". "Òàóàð", 1996, ¹2, p. 23-24.

3. Badanov K.I., Dzhumadilova R.M., Sikhinbayev J.T. The Patent of

National Patent Office under the Cabinet of Ministers of the Republic of

Kazakhstan for "Apparatus for photochemical treatment of textile

materials". Author's certificate number 14625, Republic of Kazakhstan,

1997.