CHARACTERISTICS AND CLASSIFICATION OF OBJECTS

PROTECTED GROUND

Mukatay N., Atyhanov A.K., Rozi Amut., Ospanov A.T.

Kazakh National Agrarian University, Almaty, Kazakhstan

6D080600-Agricultural

Engineering and Technology

nureke_phd@mail.ru Tel:8702-166-3-99

To plants in protected ground are artificial

agricultural buildings where year-round cultivation of vegetables. The most

perfect type of cultivation constructions protected ground are greenhouses.

This is due to the fact. They allow you to do all agricultural activities without

compromising the integrity of the fences and the widely use of various

mechanisms for the care of plants. Further, in object of the thermal management

we consider the block glasshouse. According to the source of the greenhouse

frame are classified as transparent barriers. Heat loss through cultivation

facilities is directly proportional to the surface area of the glazing and the

temperature difference. So to date we are searching for materials that have

good "transparent" as glass for optical radiation, and at the same

time, which is a good heat insulator. For example, as such material can be used

polycarbonate plates.

Existing

greenhouses industrial type can be classified on a number of operational and

construction features: by appointment seasonality, growing technology, the type

of material of the frame and translucent fencing, spacebar heating and

ventilation [1].

The

purpose of the greenhouse is divided into vegetable and seedling, and a

seedling greenhouse for growing seedlings for open and protected ground differ

in technological equipment and design of ventilation systems.

Duration: all year (winter) and seasonal

(operated in spring, summer and autumn). As a rule, the greenhouse frame is

installed in a permanent place. With the exception of mobile greenhouses,

widely spread in some North-Western regions for growing seedlings and early

greens of perennial vegetable crops.

On cultivation distinguish rack, estelline

(soil) and hydroponic greenhouses. In turn, the hydroponic greenhouses can be

fitted with different equipment in accordance with the method of growing. There

are greenhouses with traditional, classical way of supplying the nutrient

solution by the method of flooding in which plants are grown in a concrete

sealed trays or racks filled with granite gravel or expanded clay.

In recent times the wide spread of various

methods of small-scale culture of growing plants in peat-based substrate with

the use of drip irrigation systems, running water and aerovega culture,

aeroponic culture, etc.

As the material of the frame used in greenhouses

galvanized steel and aluminum profiles, wooden laminated elements.

In appearance translucent fencing greenhouses

are divided into glass and film greenhouses with a coating of hard polymer

materials. Film cover film in one or two layers. To save energy, apply special

dual-layer rigid polymer materials with an air gap between the layers 5-25 see.

On design and planning decisions greenhouses can

be divided into agrarian and block, according to the sectional profile to lean

with equal and unequal slopes, with flat, cylindrical and hyperbolic rays.

The greenhouse is the most advanced type of

cultivation constructions protected ground. Significant difference greenhouses

from other types of plants in protected ground - the ability to create

favorable conditions not only for growing plants, but also for staff and

technological equipment. As a result, greenhouses increase the productivity of

labor and production culture, disappears the seasonal nature of agricultural

work. In the greenhouse, in contrast to the small shelters and greenhouses can

without compromising the integrity of the fencing to perform all agricultural

activities, as well as widely used various mechanisms to care for the plants.

One of the first types of greenhouses Klin was a

greenhouse. She had a blank North wall and lean-to glass roof, facing South

[2]. This design provided a good thermal insulation and lighting in the winter

months. Greenhouses of similar design and is currently widely accepted and

recommended for construction on private land. One of the options shed buried in

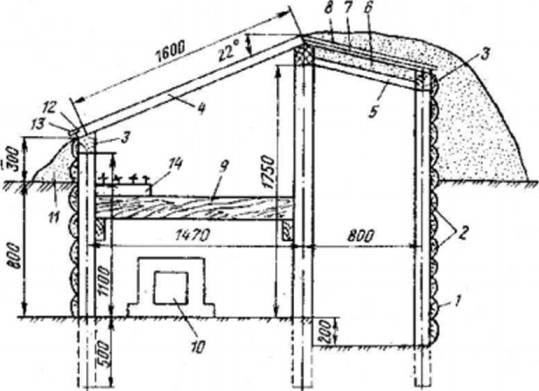

the ground of the greenhouse is shown in (figure 1).

Figure 1 - Winter lean-to greenhouse.

1 - pillars; 2 - cladding of the slab; 3 - rail; 4 - greenhouse frame; 5 -

facilities; 6 - saw; 7 - roofing; 8 - earth backfilling; 9 - rack; 10 duct; 11

- slope; 12 - resistant Board; 13 - low tide; 14 - a box of seedlings.

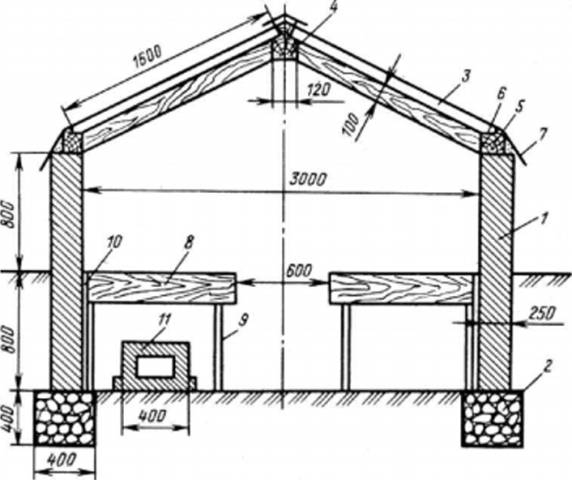

In the future, as we increase the area of

greenhouses lean-to greenhouses gave way to the gable of the hangar [3]. They

do not have any internal supports. A typical example of such greenhouses to

individual owners is a winter greenhouse with a gable roof of the greenhouse

frames (figure 2).

Figure 2 - Winter gable greenhouse.

1 - wall; 2 - Foundation; 3-rafters; 4 - ridge bar; 5 - wrap timber; 6 -

groove for the stop frame; 7 - low tide; 8 - rack; 9 -rack; 10 - the gap

between the wall and the rack; 11 -chimney

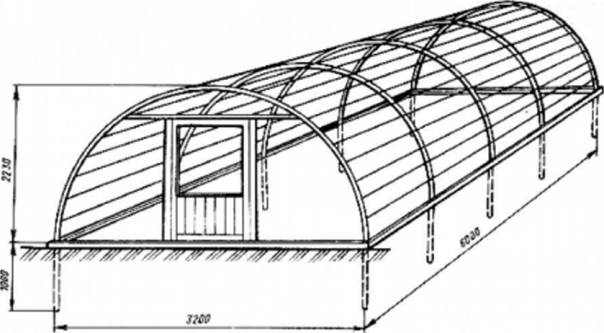

Along with gable hangar greenhouses with flat

slopes, widespread greenhouses, the sectional profile of which is close to the

arc of a circle or is a broken line (polygonal profile). As a rule, these

greenhouses are coated with a film of polymeric material (figure 3) [4].

Figure 3 - Arched

greenhouse for personal use

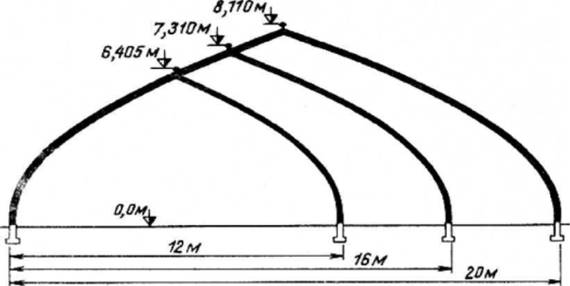

However, the cylindrical shape of the possible

accumulation of water and snow in the upper area of the roof, the formation of

"bags" and as a result, the shading of plants and the destruction of

the coating. Therefore, a more preferred hyperbolic or arrow-shaped form of the

roof (figure 4).

Figure 4 - Modification of the frames of the Finnish greenhouses

Block greenhouses include an arbitrary amount of

hangar [5]. The walls between adjacent greenhouses eliminated, leaving only the

supporting stand. Change the size of the greenhouse is possible by increasing

the number of sections and their length, which is not treparel any significant

changes in the design. This feature is widely used in practice, when based on a

standardized kit of parts to create the greenhouse area of 50 - 6000 m2.

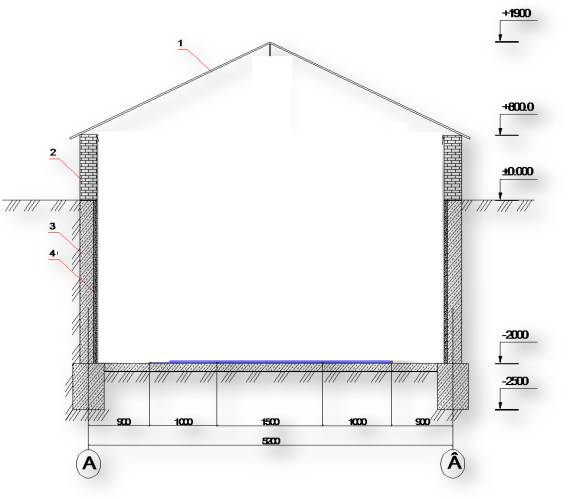

We offer underground

thermos – greenhouse

Underground thermos -

greenhouse has been installed in the training and production phase of Zhetysu

state University named I. Zhansugurov, Almaty region Taldykorgan. (Fig. 5).

Figure - 5.

Undergroundgreenhousethermos.

1 – polycarbonate , 2 – brick, 3 –

reinforced concrete wall , 4 - light reflective material.

The main feature of the greenhouse

and the thermos is economical in its consumption of energy for heating. Of

course greater efficiency savings depends on how buried this greenhouse in the

ground.

Although the greenhouse thermos can

build not buried, but the best effect to retain heat in the greenhouse is

achieved if the greenhouse is partially or completely embedded in soil. From this

stems the second feature is that the greenhouse is constructed as a trench.

The third feature reflective wall,

which is created in the greenhouse increased illumination. In cloudy weather,

this greenhouse is lighter in respectively 2 times higher than in open areas.

This gives an advantage over other greenhouses in the wintering period, as in

Sunny weather the heat inside is supported by solar energy.

The fourth feature is due to the

bright lighting and constant temperature without fluctuations is achieved yield

increases of more than 30%.

Through energy-saving

technologies to decrease costs by 45%, which contributes to a rapid payback in

2-3 years.

The measures, techniques

for installation and fastening of sheets from polycarbonate, ensuring

sufficient tightness of connections and eliminates the possibility of heat

loss.

Recommendations for the

care of the soil in the greenhouse and lighting parameters. The use of solar

energy for energy supply will help to replace from 20 to 60% of the thermal

load on the objects of agriculture, depending on climatic location, to exclude

the cost of shipping fossil fuels (important for remote users), to prevent

pollution of the environment and agricultural products.

Conclusion

In

conditions of increased requirements for new construction presented in this

paper a factor analysis of various greenhouse designs will make the right

choice taking into account the construction of greenhouses with reliability,

safety and long-term operating prospects.

Literature:

1. Automation and

electrification secure pound. Edited Prishchep LG M .: Kolos. 1996. - 320 with.

2. Designing of the

complex electrification. Edited by L. Prishchep GM: Kolos.-2003.-270 with.

3. The climatic factors

and thermal conditions in the open and protected ground. Kurtner TA .. Uskov

I-B.- L .: Gidrometeoizdat. 2002

4. Goncharuk, Lebl New

directions in automation warm microclimate. // Mechanization and

electrification of SH 2003.

5. Ways to reduce energy

consumption for heating greenhouses. // Technique milestones. 2013.