Agriculture 4. Technologies of storage and processing

of agricultural products

Assoc. Prof. V.Yu. Ovsyannikov, graduate student Yu.S.

Kraminova,

student A.S. Moskalenko, student T.S.

Kirichenko

Voronezh State University of Engineering Technologies,

Russia

Screw the mold for the refrigeration of food concentration and

body fluids

One of the main tasks of the country's food security - reducing food raw material losses. In the field of processing of food raw materials are hidden untapped potential, which could serve as additional reserves produce food. These reserves are associated with the elimination or reduction of such negative phenomena arising during processing, as a weight loss, a relatively low yield of the finished product, reducing its biological value, and others. However, to realize these opportunities based on traditional methods of treatment is extremely difficult, because these methods in its development closer to the natural limit of perfection.

In

this regard, particularly important is the development of systems for cooling

the concentrated liquid by heat exchange with intensified where energy

consumption per unit of finished product is much less. So, with a decrease in

the refrigerant boiling temperature in the equipment 1 K because of the intense

heat on the surface of the conversion of the compressor cooling capacity is

reduced by about 4% when using it in conditions close to normal; about the same

proportion increases the power consumption [1, 2].

It is also an urgent task in the food industry is now - to increase the output of food products, product diversification, further improve the quality, palatability and biological value of food as a result of the introduction of new advanced technological processes. These advanced methods of preservation of liquid food media concentration refers freeze moisture, ensuring the preservation of the original qualities of the raw material in the production of concentrates.

Concentration of the liquid food and biological fluids by moisture freezing provides the most complete preservation of the chemical composition and properties of substances in the concentrated product. Thus, this process involves the allocation of water in the form of ice at temperatures below the crystallization of pure water, which is especially important in cases of producing high-quality concentrated liquid, with energy costs to carry out a process comparable with conventional methods, and membrane methods concentrating by vacuum evaporation [3, 4].

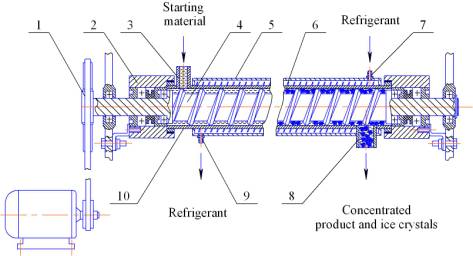

Screw crystallizer, equipped with the necessary control - measuring instruments and devices, comprises a stationary cylindrical housing 10, equipped with a heat exchange jacket 5, the heat transfer system supplies cold shirts and drive 1. Heat exchange jacket 5 has a fitting 7 for supplying liquid boiling refrigerant and fitting 9, providing drainage exhaust vapor refrigerant that circulates in the space formed by the heat exchange jacket 5 and the mold body 10 with a helical winding 6. in order to improve the characteristics of thermal power screw crystallizer all its heat exchange surfaces are equipped with thermal insulation.

Drawing. 1. Schematic diagram of the screw mold:

1 - drive ; 2 - bearing assembly 3 - nozzle supply source product; 4 - the screw ;

5 - heat exchanger shirt ; 6 - spiral winding; 7 - fitting for the supply of liquid boiling refrigerant

; 8 - an outlet for removing a mixture of concentrated product and ice crystals ; 9 - fitting for

vapor removal spent refrigerant ; 10 - the case of the mold

Inside the body of the mold in the bearing supports 2 by means of a drive 1 continuously rotates the screw 4, purifying the inner surface of the housing 10 from the mold to freeze the ice and moving mixture of concentrated product and the ice crystals to the connection 8 for removing from the mold [5]. Cheese whey to be concentrated are continuously fed to the crystallizer through conduit 8.

In the mold for freeze concentration organized countercurrent movement of the concentrated product fed through the conduit 3 and the refrigerant circulating in the heat exchange jacket 5 [6].

Literature

1.

Ovsyannikov V.Yu., Kondratyeva Ya.I., Bostynets N.I. Concentration of apple

juice in the drum freezing out installation. Khranenie i pererabotka sel'hozsyr'ja [Storage and processing agricultural] 2014. ¹ 4. pp. 41-44. (In

Russ).

2. Antipov S.T., Ovsyannikov V.Yu.,

Kondratyev YA.I., Bostynets N.I. Thermodynamic special features of the process

of the concentration of liquid media by freezing. Sovremennye naukoemkie texnologii [Contemporary science-intensive

technologies]. 2014. ¹ 5-1. 159 p. (In Russ.).

3. Antipov S.T., Ovsyannikov V.Yu., Kondratyev

YA.I. Kinetics of the process of concentration by freezing the cherry juice. Vestnik Voronezhskogo gosudarstvennogo

universiteta inzhenernyh tehnologij [Herald of the Voronezh state

university of the engineering technologies]. 2014, ¹ 4 pp. 44-48. (In Russian).

4. Antipov

S.T., Dobromirov V.E., Ovsyannikov V.Yu. Teplo- i massoobmen pri koncentrirovanii

zhidkix sred vymorazhivaniem [Heat- and mass exchange with the concentration of

liquid media by freezing]. Voronezh.

State. tech. Acad. Voronezh, 2004. 208 p. (In Russ.).

5. Patent 2221202 (Russian Federation), MKI 7 F 25 C

1/14 Crystallizer for continuous freezing

and teachings of flake ice. / S.T. Antipov, V.Yu. Ovsyannikov, A.N.

Ryazanov. – Zayavl. 30.10.2002, ¹ 2002129080/12, opubl. v B.I., 2004,

¹ 1.

6. Patent 2206839

(Russian Federation), MKI 7 F 25 C 1/14 Apparatus

for freezing and getting flake ice. / S.T. Antipov, V.Yu. Ovsyannikov, A.N. Ryazanov. – Zayavl. – 01.11.2001, ¹ 2001129629/13, opubl. v

B.I., 2003, ¹ 17.