Technical

sciences/4. Transport

Ph. D Muraviev V.V., Tapkov K.A.

Kalashnikov Izhevsk State technical university, Russia

Modeling of

the strain-stress state of the rail

Abstract. This

report contains the translations of main things of English-language articles

and literature, which are connected with railroad transport objects testing. In

first chapter translations have information about non-destructive testing of

strain-stress state of railroad rims and rails. In the second chapter it

translations describe the finite element modeling in the COMSOL program. In the

end of the report there is a glossary with the main terms, which one was found

in the literature during the translation process.

Key words: nondestructive

testing, rail, strain-stress state, modeling of strain-stress state, residual

stresses.

1 Introduction

Providing the

safety on railway roads is very important, which humanity has to decide since

the appearance of the railway transport. Due to wide spreading of the roads, increasing

of the velocities of the trains etc. the actuality of the safeness increased

too. One of the main reasons of the safety is the condition of the rails. Existence of different faults can cause dangerous accidents. It

is also the reason of the necessary of rails non-destructive testing and

developing of its methods and techniques [1]. Usually lifetime is done at the engineering

stage, but the influence of the corrosion, variable loads, high range of

temperature etc. play considerable role in decreasing of the lifetime of the

rail. At the beginning it was totally manual, and was done by human’s vision

and hearing. Nowadays there are a lot of testing devices, but methods and techniques

allow finding only big size faults, which is already in critical condition [2].

One of the main

reason of the destruction of metal objects is residual stresses. They appeared in

the time of rail’s operation, installing, welding and in the process of production

[3,4]. It is the reason why even small, not critical faults can cause the

increasing of the growing speed of cracks. With such cracks it is impossible to

use the rail [4]. So, exploring of the strain-stress state let understand

present lifetime of the rail.

2 Acoustoelastic method

One of the most suitable method for controlling

strain-stress state of the rails is acoustoelastic method. It has already been

used for controlling the stresses in railroad rims [4, 7]. For stresses, which

is controlled by its technique, there is following evaluation (1) [2, 5]:

![]() (1)

(1)

D=145 GPa – acoustoelastic coefficient, which was found

by experimental way, a0 – parameter

of acoustic anisotropy, Δt – time

delay of the receiving of acoustic waves, sec., t1 – time of the wave spreading along the rail, sec.

But officially

(GOST standart [6]) the universal method have following steps: you have to make

a notch in the rail 600 mm long, and in case if the head and pad of the rail

have relative displacement 2 mm or more, this rail is defective.

3

Modeling of the displacement of notch

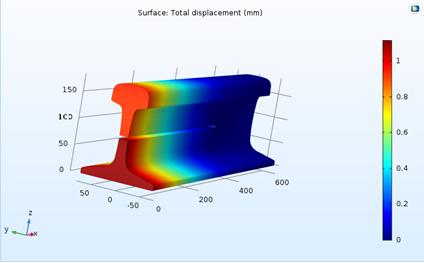

For making

the model, it was decided to make the pair of forces, which press on different

parts of the rail. They create torque, which cause the displacement in Z-axis.

Modeling was

made in program Comsol Multiphysics. For studying it was used Solid mechanics module.

Evaluations were made by finite-element method (FEM). As a fixed constant it

was choosed the plane surface on another side of the rail. The results of the

modeling is shown on the fig. 1.

Fig. 1 Displacements with notch

This value of

the displacement was get in case of power 56 MN/m2.

4 Results of modeling

strain-stress of the rail

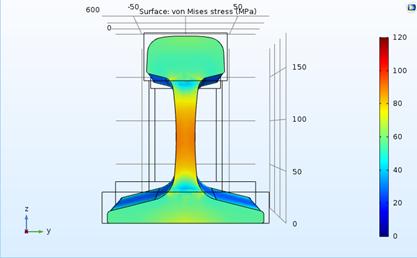

On the figure

2 it is shown the stresses in the rail, which were calculated by von Mises

theory. As you can see, maximum volume of the stresses is situated in the middle

part of the rail, and consists nearly 80 MPa.

Fig. 2 Stresses in the rail

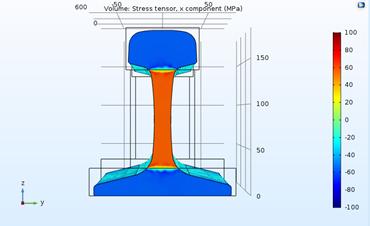

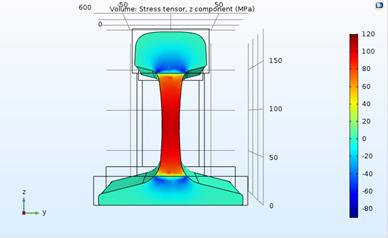

Also it was

made the modeling in X-axis (Fig. 3) and Z-axis (Fig. 4).

Fig. 5 Stresses in X-axis

Fig. 6 Stresses in Z-axis

5. Conclusion

1. The model

of the rail was created. This model allows explore the influence of the

stresses on the displacement of the rail with notch.

2. It is

proved, that the biggest volume of the stresses is situated in the middle part

of the rail.

3. There are

stresses in all parts of rail in X-axis, but there are stresses only in the

middle of the rail in Z-axis.

Literature list

1. The strategy of the

development of Russian railway roads till 2030 // Russian wallpaper, ¹6358,

16.04.2014

2. Murav’ev V.V., Volkova L.V.,

Gromov V.E., Glezer A.M. Estimation of the Residual Stresses in Rails Using

Electromagnetic–Acoustic Introduction–Reception of Waves, Russian Metallurgy

(Metally), Vol. 2016, No. 10, pp. 1002–1005.

3. Stepanova L.N., Bekher S.A., Kurbatov

A.N. etc.

Studying of the stress-strain state of the rail with help of acoustoelastic

method. – University news. Engineering, 2013, ¹7, p.103-109.

4. Muravev V.V.,

Volkova L.V. Evaluation of the interference value for the treads of locomotive

wheels by the acoustic elasticity method. Russian Journal of Nondestructive Testing.

2013. Ò. 49. ¹ 9. Ñ. 524-529.

5. Murav’ev V.V., Volkova L.V., Platunov A.V.

and Kulikov V.A. An Electromagnetic-Acoustic Method for Studying Stress-Strain

States of Rails. - Russian Journal of Nondestructive Testing, 2016, Vol. 52,

No. 7, pp. 370–376.

6. GOST 51685-2013 Railway rails.

General specifications. Ì., 2013. 101 p.