Alexander N. Podobry

Ulyanovsk State Technical University, Russia

Integration Method Design for Common Corporate Data

Warehouses

Any manufacturing enterprise is mainly concerned with the timely output of

finished products. Achievement of this goal requires tracking the product lifecycle

from conclusion of a development contract to testing and transfer of finished

products to the Customer. The cycle itself includes tracking of the requests for

material procurement, acceptance of the design and engineering documentation,

etc.

A problem arising when designing a computer-aided system for tracking the

product lifecycle is that the data storage sources are dispersed. The role of these sources plays corporate data warehouses [2].

A corporate data warehouse is the integrated gallery of data, which are structured

and collected from diverse information sources. It gives an opportunity to

analyze the data accumulated and forms the basis for designing decision-making

systems.

There are a lot of ready-made solutions which help to resolve this task in some

degree, e.g., PDM (Product Data Management) and PLM (Product Lifecycle

Management) systems [3,4]. As a rule, systems like these ones are

expensive and provide for a general task solution. Anyway, these systems to be

used at maximum, all corporate data warehouses shall be integrated in one

information space of the company.

The main approaches include the integration of: data, business-processes,

applications and user interactions.

The data integration gives a common

representation of all information objects within a company, at all production

and business-process levels.

The dispersed-application

integration level allows controlling the streams of events and application

management within the context of transactions, messages or data.

The business-process integration is to

define and implement processes of exchange and implementation of corporate data

between corporate date warehouses.

The user-interaction integration gives a common

interface for access to corporate data warehouses taking into account personal

and safe access level. This type of integration allows aligning users’

interoperation with a full range of the data given.

The data

integration forms a basis for all the integration approaches mentioned. It is

the basis which defines the integration success at all other levels of an

information system. The main methods for integration of corporate data are:

consolidation, federalization and dissemination [1].

When using the consolidation method, data are collected from

several primary systems and integrated into one permanent warehouse. Applying

the data- federalization method, a common information cyberspace appears

where data may be stored in different sources at that the requesting side has

no access to the information on the data location. Finally, it is the dissemination

method where data are transferred from one system to another.

Each method mentioned has the advantages

and disadvantages. When using the consolidation method, a time delay may occur

between the moment of the data update in primary systems and the time when

these changes appear in the final storage location. The advantage of this

method is in aggregating (aligning) of data during transfer of information to

the final warehouse. The advantage of the federalization method is that it

allows the access to the requisite data and excludes the need in data transfer

from one warehouse to another. The disadvantage of this method is the cost

associated with productivity and access to multiple data warehouses. A big advantage

of the dissemination method is that it can be used for data transfer in real-time

mode or close to it. Other advantages include the secured data delivery and

two-way data dissemination.

There is a

hybrid data-integration method which consists of some of the methods mentioned

above. This method is applied when an independent use of one method is

impossible.

The use of one of the methods mentioned within a

manufacturing enterprise doesn’t allow the integration problem to be fully resolved

for independent corporate-data warehouses. It depends on such factors as independence,

productivity, dissemination ability of corporate warehouses, etc. As a result, a

method is requested to combine all the methods mentioned and to allow integrating

corporate warehouses which are physically located in separate networks.

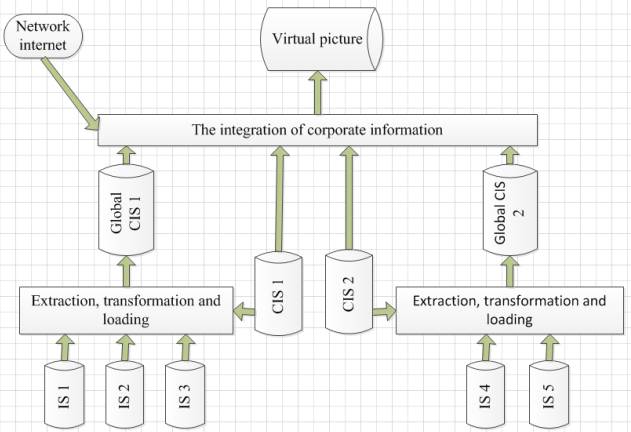

An option to resolve this issue is

the use of a hybrid method of consolidation, federalization and dissemination

(figure 1). The basis for this method relies on the metadata structure which

combines different independent corporate warehouses.

Fig.1. Hybrid Method for Integration of Corporate Data Warehouses.

The consolidation method is used to collect

data from child warehouses, and the dissemination method – to integrate with

warehouses which are geographically or physically located in different

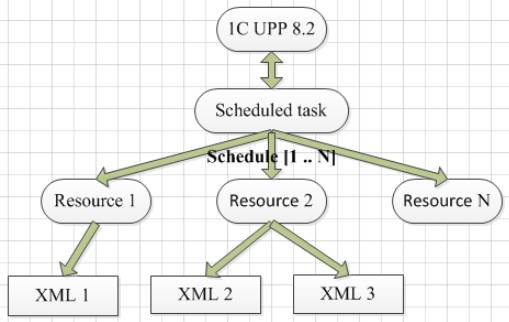

networks. To communicate to the last ones, the xml-upload facility may be used (fig. 2).

Figure. 2 Structure of Data Representation to Web-Resources

This facility is based on the

algorithm for uploading data in xml-format, which allows the data to be updated

and the structure of a corporate warehouse to be sinchronized. The xml-file

itself includes the

following:

- list of tables;

- list of table

fields;

- key fields of

tables;

- data loading

method;

- data set.

Thus, the suggested

method allows designing of a common data-storage structure due to the

integration of independent data warehouses into one information space within a company.

The xml-upload facility allows supporting the integration both with information

systems, where the access to the database is denied, and with remote data

warehouses, e.g. the Internet. It helps to track a product lifecycle and to promptly

respond to possible delays and problems with the product output.

BIBLIOGRAPHY:

1. Tanenbaum, Andrew S. Distributed systems: principles

and paradigms / Tanenbaum, Andrew S.; Steen, Maarten van. – Saint-Petersburg: “Piter”

Publishers, 2003. – 877 p.

2. Kudinov, Alexander. Data Warehouse as the Basis of

Corporate Integration. Edition: PC Week/RE.

Date: 2006,

Intersoft Lab

3.

Dubova , Natalia. Systems for Control of Production Data. “Otkrytiye Systemy”, 1996 , #3

4. Kevorkov, Sergey. Support of the Product Lifecycle / “Otkrytiye

Systemy”, 12, 2005