Engineering sciences

Ibragimova

S.I., Polischuk V. I.

TRANSPORTATION PROCESS CONDITION`S INFLUENCE ON

THE OPERATION OF LOCOMATIVE TRACTION OF THE INDUSTRIAL RAILWAY

Ekibastuz technical

engineering institute named after Academician K.I.Satpaev Ekibastuz E-mail: ibrsvetlana@mail.

ru

It is considered the main features of operation

The main features of maintenance of locomotive traction assemblies OPE-1 on cuts of the Ekibastuz opencast colliery operation condition

of locomotive traction motors NB-412P, data about malfunction the reasons of

their origination and measures increasing its reliability of traction motors at

an industrial railway transportation are state

I. Introduction. Traction motors are concerned

as the most loaded equipment of electric locomotives ( ELT). According to data

specialists of the Project and design bureau of locomotive transport open

joint-stock company «Russian railways» (LPDDB JSC RR Open Society "R.R-

Russian Railways") principal views of failures ELT are connected with

punctures of isolation of windings, turn-to-turn faults (TTF), decrease in an

insulation resistance of armature windings and poles which make 34-47 % from the

general number ELT, failed in 2006-2008 years. Expenses of Open Society

"JSC -RR" for repair ELT have made for 2003-2008 years more than 6

billion rbl. [1]. Research and elimination of the reducing reasons of decrease

in resource ELT is an actual problem.

II. The Statement of problem. On cuts

of the Ekibastuz opencast colliery of operational condition ELT more

complicated than on the main ways: a height above sea

level about 1200 m, humidity of air to 90 % at 20 îÑ, a complex plan and a way profile (curves in radius 200ì, insignificant length of

sections with grades to 60 ‰); a temperature varying range(from-43 to +40 îÑ) [2]; the quantity of

start-ups per days at times attains 1500, and changing direction of an armature

to 300; frequent the wheel pairs, originating in a loading regime and at

traffic on exit trensh [3]. Therefore it is necessary to spend

qualitative analysis of features of damageability ELT in the conditions of

Ekibastuz coal cuts.

III. Results. There

are more than 500 ELT in operation at the Limited liability companies

"Bogator Komir" (Open Company "BÊ") the faults which made up in

2007-2008 years have made 43-46 % from the general failure of traction

assemblies. According to the data of railway equipment repair of emergency shutdowns of traction assemblies OPE-1 because

of falling out ELT NB-412P it is possible to outlined repeating derangements:

short circuit of excitation windings on the case, short circuit of closed

armature winding, turn-to-turn windings, soldered connection commutate neck of

a collecting channel, a slide of a small sprocket from the armature shaft, an

armature shaft dog-leg. Distribution of basic failures ELT NB-412P for

2007-2008 years is shown in Table 1.

Table 1

Distribution of basic failures ELT NB-412P for 2007-2008

|

¹ |

The fault’s name |

Share in % |

|

1 |

Test of isolation and TTF armature windings |

33 |

|

2 |

Test of isolation and TTF main-pole windings |

11 |

|

3 |

Test of isolation and TTF windings of

additional poles |

6 |

|

4 |

Test of isolation and TTF the compensating field |

5 |

|

5 |

Reduction of isolation of anchor and polar windings |

3 |

|

6 |

Faults of connectors |

8 |

|

7 |

Faults of anchor bandages |

2 |

|

8 |

Faults of anchor bearing |

5 |

|

9 |

Armature shaft breakage |

8 |

|

10 |

Faults of connection poles |

3 |

|

11 |

Faults of brush knots, crossarms |

3 |

|

12 |

Collecting channel faults |

7 |

|

13 |

The others |

6 |

From

table 1 it is seen, that the greatest percent of ELT faults makes isolation

test, TT an armature winding and the main poles. From a distribution bar graph

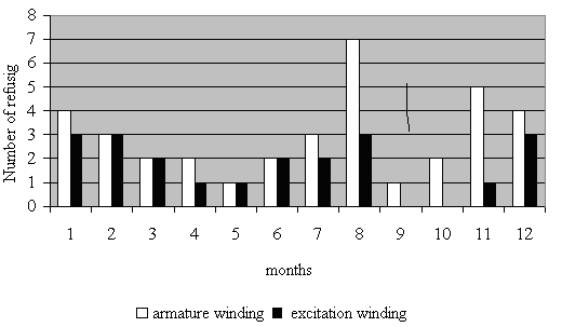

on months for 2007-2008 (drawing 1) it is visible, that maximum quantity TTF originates in the coldest and hottest months.

Drawing 1 Bar

graphs of isolation failures windings

of armatures and excitation ELT NB-412P of traction assemblies OPE1 of the

Powerful complex for 2007-2008 years

Principal causes

of failures ELT low efficiency snow fence devices, hit of a coal dust in crazes

of the multilayered insulating varnishes an unsatisfactory condition of a way

with the raised rigidity. Promoting factors are: infringements of a regime of

maintenance, sharp differences of voltage in the contact network, the increased

temperature conditions, the reinforced loading at the expense of weight norms

and heavy grades, an overloading of propellers at traffic on exit òðàíøåå, insufficient

cooling.

Elimination

of these failures and planed repair works and routine maintenance make the

basic share of expenses under contents ELT in maintenance.

The

considerable part of faults ELT can be eliminated only at factory repair which in repair depots on

railway equipment repair is not carried out, and on external baselines was not

carried out since 1995. In locomotive shed repair

depots of Joint Company "BÊ" operating repairs (RR) are carried out only in

which volume at ÒÐ-RR1

diagnosing ELT by devices of Open Company "Transport" of Omsk («the Doctor 030», ILP-1,

"Cedar", "Forecast", A contact less thermometer) on

following parameters is done : resistance case and the interterm insulation,

humidity factor; in volume RR-2, RR-3 – broach connection, replacement

partially the compensating winding, replacement partially compoles, a coating

method of dipping in the ML varnish, TO; in volume of capital repairs - replacement

case and partially the interterm- insulation, replacement of bearings,

restoration of cones of a shaft and beds of motorno-axial bearings, a coating

method dipping in the ML varnish, TO (the operating time makes 2,5 - 4 years).

Quality of repair not always meets the installed demands.

IV. Leading-outs.

From the

above-stated follows, that existing methods of the account and elimination of

failures ELT do not allow making qualitative analysis and absence of planned

factory repairs reduces their resource. It is necessary to develop

scientifically proved technical and organizational provisions to rise of

resource ELT, considering features of operating conditions of traction

assemblies OPE-1 on Ekibastuz coal cuts.

The literature:

1. O.L.Rapoport,

D.N.Homchenko. Necessity of the system of monitoring of a thermal condition of

railway motors.//the Locomotive. - 2009. - ¹ 5. - ñ.37.

2. Open Company

"Karaganda". Technical and economic account for choice conducting

production mining engineering on a cut "Bogator" of Open Company

" Bogator Access Komir". Volume 1, ELT 7220-SHZ. - Karaganda.: 1998 ñ.17.

3. Potapov M.G.Remont of an

electrorolling stock of industrial transport. - Ì: Transport, 1982 - ñ.155.

Polichshuk Vladimir Iosifovich - the manager of

chair "Electric power industry" of Ekibastuz Technical Engineering

Institute named after academician K.Satpayev, a Cand.Tech.Sci. Graduted from

the Pavlodar Industrial Institute in 1990ã. Department of

"Electric generating plants". The dissertation was defended in 2007ã. at Omsk State Technical University on a theme

«Development of the theory of construction and protection of a rotor of the

synchronous generator from turn-to-turn short circuits»

Home address: 141216 Republic Kazakhstan, Pavlodar provence, Ekibastuz,

Solar Green journey 1, sq. 55.

Ibragimova Svetlana Ivanovna - the senior

lecturer of chair "Transport" of Ekibastuz Technical Engineering Institute named after academician K.Satpayev. graduated from the Ural

Electromechanical Engineering Institute of the department railway transportation in 1972.

"Electrorolling stock".

Home address: 141216 Republic Kazakhstan, the Pavlodar provence,

Ekibastuz, Lenin's street, 68, apt. 80.

.