Agriculture 4. Technologies of storage and processing

of agricultural products

Assoc. Prof. V.Yu. Ovsyannikov, student A.N. Denezhnaja,

student T.S. Kirichenko, student Yu.S. Kraminova

Voronezh State University of Engineering Technologies,

Russia

The design of the tubular section of

the mold for

the concentration of liquids freeze

The use

of modern methods of concentrating liquid food environments based on advanced

science and technology creates favorable prospects for high quality

concentrates in the processing of large volumes of fruit enough raw materials

with minimum labor costs. Expansion of production of natural and concentrated

juices, extracts of tea, coffee, production of elite wines thickening enzyme

solutions, blood plasma, preparations of extracts from the organs of

slaughtered animals and other liquid media food and biological applications on

large highly mechanized enterprises is only feasible through the introduction

of new high-performance, energy-efficient appliances and advanced technology,

one of which is the concentration of liquid food media freeze.

Concentration

of food and biological media by freezing moisture provides the most complete

preservation of the chemical composition and properties of substances in the

concentrated product. At the same time, this process involves the allocation of

water in the form of ice at temperatures below the crystallization of pure

water, which is especially important in the case of production of concentrated

fruit and vegetable juices of high quality products for children and dietary

food, with energy costs of the process are comparable to traditional methods of

concentrating the membrane and a vacuum evaporation method [1].

Processes

concentrating food liquids by concentrating refrigeration especially

appropriate in cases where the mixture contains components shared extremely

unstable even in a slight increase in temperature, which include primarily

amino acids such as lysine, tryptophan and cysteine, which undergo significant

structural changes in the molecular chain, even at temperatures of the vacuum

evaporation, the components of the order of 333 ... 343 K, sugar, coloring and flavoring.

By increasing productivity and reducing heat and mass

transfer equipment energy consumption for processing of liquid food and

biological materials is the creation and implementation of effective

technological equipment with low specific energy and materials having a high

impact on the environment to be treated. This requires new engineering

teplomassoobmennyh equipment using intensive methods effect on work environment

created on the basis of advanced engineering - technical research [2].

In

plants the concentration of liquid foods freeze moisture exploit different

types of molds, different features work, structural design and surface area of

cooling. [3 – 5].

Multi-system

concentration of liquid products involve the use of several steps, the first of

which is an intensive nucleation, then provide the conditions for their growth

and consolidation, followed by separation of ice and concentrated solution.

Typically, nucleating requires intensive cooling and mechanical action, so are

used for this purpose scraper with the tubular molds mixing devices of various

designs.

In such crystallizers "pipe in pipe" by moving the inner pipe

is cooled by liquid product from which crystallizes in the form of ice water,

and the annulus moves counter currently low temperature refrigerant or

refrigerant boils.

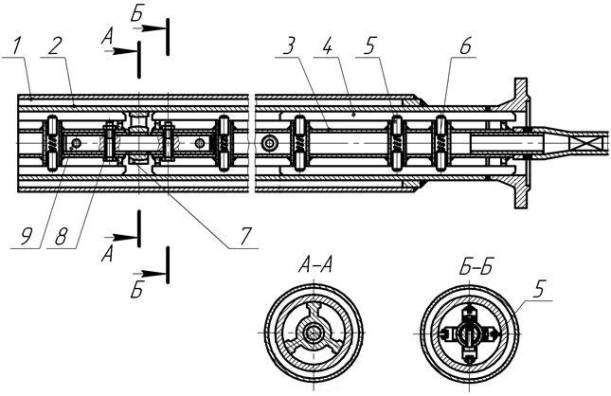

Section crystallizer "pipe in pipe" (Fig. 1) consists of an

outer tube 1 and inner tube 2 of smaller diameter inserted into each other.

Fig. 1. An element of the mold section:

1 - the outer tube; 2 - the case of the inner tube; 3

- shaft; 4 - scraper;

5 - finger; 6 - spring; 7 - the slide bearing; 8 - a

bolt; 9 - pin

The internal tube to remove the ice deposited on the wall of the hollow

shaft 3 is mounted with scrapers 4. Crystallizer’s high performance due to the

considerable length of the pipe shaft may be made of separate parts. Separate

link shaft is a tube 3 with welded into it cylindrical sleeves to install

scrubbers 4. The links connect the shaft insertion rod bolts 8 and 9.

Scraper fingers inserted into the grooves 5 and can be

welded thereto. Fingers free entry to the cylindrical shaft sleeve and bursting

springs 6. This creates the possibility of moving the scraper in the radial

direction. The scrapers are arranged in pairs on the shaft at a 90º angle

relative to one another. Each scraper has three spring-loaded supports, and

each scraping device several pairs of scrapers.

Shaft mounted inside the tube in bearings 7. The front

ends of the shaft coming out of the doubles sealed Gland. The difference

between the thermal expansion of inner and outer tubes perceived wavy (lens)

compensators. Drive shafts made engine - gearbox through the drive sprocket.

A driven sprocket mounted on the drive shaft of the

scraping device. For torque transmission is used duplex chain drive. The outer

tube is also connected through a common adapter stamped coil.

Outside the housing unit in any link of the drive

(gear, clutch) provide for the safety pin, which is cut off when excessive

force arising from the binding or other malfunctions in the scraping device. As

a result, the scraper device is disconnected one pipe while the other continues

to operate.

It should be noted a number of positive features

inherent in the developed design section of the mold for freezing liquids.

Production and execution of individual sections of

parts and does not require sophisticated equipment and technical accessories.

The construction of the section of the mold is simple in design and reliable in

operation. Maintenance is easy enough and is not intended to attract highly

qualified staff.

Control and regulation of the amount of ice in the

frozen section may be implemented as a change in the heat load on the liquid

medium to be treated and mode of mixing and purging the internal cylindrical

surface of the frozen layer of ice consumption of starting material fed to the

concentration and duration of exposure under continuous stirring mixture of ice

and concentrate section.

The use of such structures will significantly simplify

the design scraping mold used for the separation of liquid products by

freezing.

Ëèòåðàòóðà

1. L.

Pap Freeze concentration. Translation. with Hungarian, edited by O.G.

Komyakova. - M.: Light and Food Industry, 1982. - 97 p.

2. Ovsyannikov

V.Yu. Study of the process of freezing moisture from the extracts of the

endocrine and special raw material. Diss. cand. tech. the sciences. Voronezh.

State. tech. Acad., 2003. 184 p.

3. Patent 2221202 (Russian Federation), MKI 7 F 25 C 1/14 Crystallizer

for continuous freezing and teachings of flake ice. / S.T. Antipov, V.Yu.

Ovsyannikov, A.N. Ryazanov. – Zayavl. – 01.11.2001, ¹ 2001129629/13, opubl. v

B.I., 2003, ¹ 17.

4.

Patent 2206839 (Russian Federation), MKI 7 F 25 C 1/14 Apparatus for freezing

and getting flake ice. / S.T. Antipov, V.Yu. Ovsyannikov,

A.N. Ryazanov. – Zayavl. –

01.11.2001, ¹ 2001129629/13, opubl. v B.I., 2003, ¹ 17.

5.

Patent 2220385 (Russian Federation), MKI 7 F 25 C 1/14 Apparatus for producing

flake ice. / S.T. Antipov, V.Yu. Ovsyannikov,

A.N. Ryazanov. – Zayavl. –

05.04.2002, ¹ 200210877/3, opubl. v B.I., 2003, ¹ 36.