Changes in thermal

conductivity of building materials

as a consequence of

vapor condensation

Jan

Skramlik, Ondrej Fuciman, Miloslav Novotny

Brno University of Technology, Faculty of Civil Engineering, Institute

of Building Structures,

Veverí 95, 602 00 Brno,

e-mail: skramlik.j@fce.vutbr.cz, fuciman.o@fce.vutbr.cz

Abstract

In

construction work, we often deal with structures which are not allowed to

contain a great amount of moisture; however, in other structures, raising the

amount of moisture does not pose any risks to the insulation layers, nor does

it cause thermal conductivity to increase. In quite a number of cases, moisture

causes certain physical properties of the materials to deteriorate, rendering them

useless for construction work.

1.

Introduction

The Czech norm 730540 standard only deals with accumulating moisture in

building constructions. The amount of moisture that accumulates in the winter

months should ideally be equal to or less than the amount of moisture that

evaporates in the summer. The standard does not seek to monitor the thickness

of the layer of material affected by condensation, nor does it attempt to find

out whether the increased moisture levels have a negative effect on the thermal

insulation layer, rendering it, in extreme cases, utterly ineffective.

2.

The

effect of moisture on thermal conductivity

The effect of moisture on thermal conductivity of materials is vast. It

differs with different temperatures and the dampness of the respective

material. Research has shown that in the case of dry materials, temperature and

atmospheric pressure do not affect thermal

conductivity (in the common temperature range). However, in the case of damp

materials, at certain temperatures and certain pressure values, the so-called

'diffusional thermal conductivity' prevails over molecular thermal conductivity

of air in air ducts, affecting negatively the thermal conductivity of the

material as a whole. Therefore, thermal conductivity is a variable that is

subject to changes in dampness, temperature and pressure in a particular

material.

It is interesting to note that in the diffusion process, materials that

are normally waterproof absorb a great deal of moisture. Such materials do not,

under normal conditions, absorb any water; it only spreads to the cracks and

pores that are on the surface and later on evaporates into the outer space

without penetrating the material. This happens, for instance, to good quality

polystyrene with closed pores, if exposed to moisture. However, in a number of

cases, a sample of polystyrene taken from a building site was proven to contain

so much moisture that it lead to a fivefold increase in its weight. This is due

to the penetration of water vapor into the molecular structure of polystyrene.

The aforementioned standard and its

insufficient calculations allow us to focus merely on the quantity of condensed

moisture while overlooking the changes in the qualities of materials subjected

to condensed moisture in winter. These changes may not always be insignificant,

even though the ratio of condensed and evaporated moisture might, at the same

time, comply with the standard. The calculations provided by the standard may

therefore never be taken as absolute. Depending on the composition of the

peripheral structure and the construction of the roof, the increase in thermal

conductivity may be minimal for certain materials; however, if the intensity of

the diffusion flow is great, it needs to be taken into account.

|

|

|

|

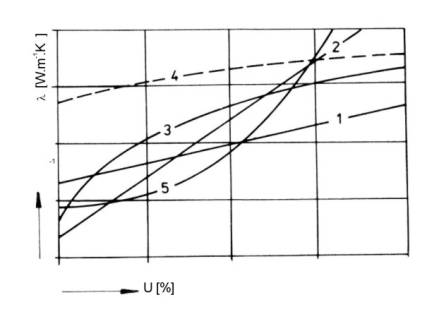

Fig.1 Thermal conductivity coefficient

in relation to moisture (functional dependence) |

The thermal conductivity of water (in all its states) depends on its

temperature. Temperature affects the thermal conductivity coefficient also in

solid materials; an increase in temperature results in an increase in the value

of the coefficient (in temperatures both below and above zero).

Knowing the relation between moisture and the thermal conductivity

coefficient allows us to use a particular moisture value to calculate the

corresponding value of the thermal conductivity coefficient. The variables

measured are visualized using the semi-graphical method. The most elementary

relationship is a linear relationship (lines 1 and 2 in Fig. 1). It is expressed

by a straight line equation [4]:

![]() [W.m-1.K-1] (1)

[W.m-1.K-1] (1)

or in this form:

![]() [W.m-1.K-1] (2)

[W.m-1.K-1] (2)

lw – thermal

conductivity coefficient for a damp material [W.m-1.K-1]

ls - thermal

conductivity coefficient for a dry material [W.m-1.K-1]

u – volumetric moisture content of the respective material [% obj.]

gl - moisture coefficient of thermal conductivity which expresses the

percentage increase in thermal conductivity of a dry material based upon the

percentage increase in the amount of moisture [-]

A – a linear constant obtained using the semi-graphical method from the

relation measured between the two variables: l = f (w).

The other curves represent exponential or

parabolic functions. It may also, however, take the shape of a power

polynomial:

![]() [W.m-1.K-1] (3)

[W.m-1.K-1] (3)

Aside from the functions expressed by (1), (2)

and (3), a number of other functional relations lu = f (u) were created [4]::

![]() [W.m-1.K-1] (4)

[W.m-1.K-1] (4)

![]() [W.m-1.K-1] (5)

[W.m-1.K-1] (5)

![]() [W.m-1.K-1] (6)

[W.m-1.K-1] (6)

Thermal conductivity increases with an increase in temperature. This

applies to temperatures both below and above zero. A significant increase in

thermal conductivity can be detected only at very high temperatures, which are

very uncommon in the building construction context. The temperature applied to

building materials hardly exceeds 70 or 100°C.

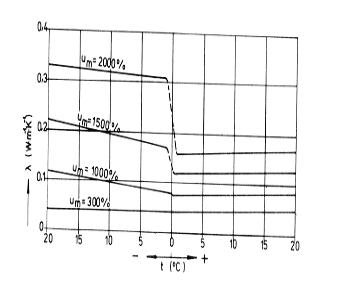

Temperatures below zero offer an entirely

different picture. The thermal conductivity of ice is roughly four times

greater than the thermal conductivity of water. If all the holes and bubbles in

the material are filled with ice, the thermal conductivity coefficient of the

frozen material is somewhere in between the thermal conductivity of ice (lv = 2,3 W.m-1.K-1) and the thermal conductivity of the material itself. Below

freezing point, when water (with the following value of thermal conductivity - lv = 0,59 W.m-1.K-1) inside the material turns into

ice, the thermal conductivity of the material in question rises dramatically.

The greater the moisture, the more water turns into ice and the greater is,

then, the thermal conductivity coefficient of the frozen material. Research

measurements have supported this hypothesis. In Fig.2, we can see changes in

the thermal conductivity coefficient of polystyrene.

|

|

|

|

Fig.2 Thermal conductivity of expanded

polystyrene in relation to moisture and temperature |

The number of new materials is growing rapidly and building research,

quite naturally, lags behind with devising new technologies and creating

projections. Therefore, research results need to be generalized to such an

extent that the functional relations

sufficiently characterize the behavior of materials based on changes in

density, moisture and temperature.

A. Polansky postulated general relationships between the thermal

conductivity coefficient and volumetric moisture content for building

materials, which is expressed in the following form:

·

for uv = 0 %

(dry material)

![]() [W.m-1.K-1] (7)

[W.m-1.K-1] (7)

·

for uv = 5

%

![]() [W.m-1.K-1] (8)

[W.m-1.K-1] (8)

·

for uv = 10

%

![]() [W.m-1.K-1] (9)

[W.m-1.K-1] (9)

·

for uv = 15

%

![]() [W.m-1.K-1] (10)

[W.m-1.K-1] (10)

By means of adjusting the aforementioned relationships, we may devise

the following equation, which describes thermal conductivity in relation to

moisture and density:

![]() [W.m-1.K-1] (11)

[W.m-1.K-1] (11)

J. S. Cammerer expressed the relationship between the thermal

conductivity coefficient and moisture by means of the moisture coefficient of

thermal conductivity gl from the equation in (2):

![]() [W.m-1.K-1] (12)

[W.m-1.K-1] (12)

The values ls gl inserted into the equation are taken

from norms and regulations, or from the data provided by manufacturers.

3.

Analysis

of the moisture coefficient of thermal conductivity

Thermal transmission in damp materials occurs

in three different ways:

·

in a

solid material lc,

·

in a

liquid lv,

·

in a

mixture of air and vapor la.

The value of the moisture coefficient of thermal conductivity gl expresses the percentage increase in

unit thermal conductivity in a dry material, in relation to every one

percentage point of volumetric moisture content [5]:.

3.1 Thermal conductivity in dry

materials

Thermal transition in dry materials occurs in

its solid content as well as in the mixture of air and vapor that is found in

its pores and bubbles.

![]() [W.m2.K-1] (13)

[W.m2.K-1] (13)

ls – thermal conductivity coefficient of a dry

material [W.m-1.K-1]

V – overall volume of the dry material [m3]

la – thermal conductivity coefficient of the

mixture of air and vapor [W.m-1.K-1]

Va – the volume of the mixture of

air and vapor [m3]

lc – thermal conductivity coefficient of the dry

component [W.m-1.K-1]

Vc – the volume of the dry component

[m3]

If we introduce the porosity of a material [-] p into our calculations, then:

![]() [-] (14)

[-] (14)

![]() [W.m-1.K-1] (15)

[W.m-1.K-1] (15)

3.2 Thermal conductivity in damp

materials

In contrast to what happens in dry materials, thermal transmission in a

damp material occurs not only in its solid component and the mixture of air and

vapor in its pores, but also in the water (or ice) that is present in the pores

and bubbles of the material [5]::

![]() [W.m2.K-1] (16)

[W.m2.K-1] (16)

lw – thermal conductivity coefficient of the damp

material [W.m-1.K-1]

V – overall volume of the damp material [m3]

la - thermal conductivity coefficient of the

mixture of air and vapor[W.m-1.K-1]

Va – volume of the mixture of air

and vapor [m3]

lc - thermal conductivity coefficient of the

solid component[W.m-1.K-1]

Vc – volume of the solid component [m3]

lv - thermal conductivity coefficient of water

(or ice) [W.m-1.K-1]

Vv – volume of water (ice) [m3]

(Va – Vv) – volume of the

mixture of air and vapor minus volume of water [m3].

![]() [W.m-1.K-1] (17)

[W.m-1.K-1] (17)

If we insert (14) into (17) and reduce the

equation, we arrive at the following equation:

![]() [W.m-1.K-1] (18)

[W.m-1.K-1] (18)

From the definitions of mass and volumetric

moisture content:

![]() [-] (19)

[-] (19)

![]() [-] (20)

[-] (20)

w – moisture content by weight [%]

u – volumetric moisture content [%]

rs – density of the dry material [W.m-1.K-1]

rv – density of water (ice) [W.m-1.K-1]

Inserting (19) and (20) into (18), we arrive at

the following equation [5]:

![]() [W.m-1.K-1] (21)

[W.m-1.K-1] (21)

![]() [W.m-1.K-1] (22)

[W.m-1.K-1] (22)

Inserting (15) into (21) and (22), we arrive at

the following equations:

![]() [W.m-1.K-1] (23)

[W.m-1.K-1] (23)

![]() [W.m-1.K-1] (24)

[W.m-1.K-1] (24)

3.3 A comparison with the moisture

coefficient of thermal conductivity

J. S. Cammerer expressed the relationship between the thermal

conductivity coefficient and moisture by means of the moisture coefficient of

thermal conductivity gl. A comparison can be made using either moisture content by weight or

volumetric moisture content, using the equation in (2) [1]:

![]() [W.m-1.K-1]

[W.m-1.K-1] ![]() [W.m-1.K-1] (25)

[W.m-1.K-1] (25)

Inserting (23) and (24) into the calculation,

we arrive at the following:

![]()

![]() (26)

(26)

![]() [-]

[-] ![]() [-] (27)

[-] (27)

![]() [-]

[-] ![]() [-] (28)

[-] (28)

4.

The

effect of water vapor condensation on thermal conductivity

There are a number of different opinions regarding the condensation of

moisture in building constructions. However, the prevailing opinion states that

there is no reason to prevent condensation; nevertheless, it needs to be kept

within certain boundaries.

In the case of a single-ply flat roof, with the typical layout of

layers, preventing moisture from leaking through the construction in the form

of water vapor and condensing inside is next to impossible. The high vapor

resistance of the roof cover causes moisture to condense right below it, where,

in most cases, thermal insulation can be found. Water vapor has the ability to

pervade the molecular structure of materials that otherwise have a low

absorption rate. This vapor can then condense in the pores of the material and

the moisture content of the material rises, quite contrary to our expectations.

The calculations based on the CSN 730540 standard are only concerned

with the quantitative evaluation of moisture content. However, the qualitative

influence, as it has an effect on the insulation properties of materials, may

cause an undirected increase in moisture content, because changes in insulation

properties over time bring about changes in the thermal and diffusion layout of

the construction, reducing thermal transmission resistance.

In a test sample of fibrous insulation material with a thickness of 100

mm and a thermal gradient of 35 °C in temperatures above zero, the results

of calculations that took into account the influence of the moisture coefficient

of thermal conductivity gl differ from the results of the

calculations mentioned in the standard by as much as 7 %, in terms of the

increase in the amount of condensed moisture, for a mere period of seven days.

The thermal resistance of the sample decreased, in the same period of time, by

8 %.

Temperatures below zero offer space for much more significant

differences. This is due to the fact that the thermal coefficient value (l) depends, amongst other factors, on

temperature. Temperature does not play a major part; however, if a phase change

occurs within the material, thermal conductivity of the material increases

dramatically, often by hundreds of percentage points [3]:.

In construction practice, water vapor condenses in single-ply flat roofs

with a typical layer layout right under the roof cover. In winter months, the

temperature there is nearly always below zero. Therefore, the condensate is not

water but ice.

Acknowledgements

This paper has been written while

working on partial tasks entailed in the research proposal MSM0021630511

“Progressive building materials using secondary raw materials and their impact

on service life of structures”, with a particular material support by Faculty of Civil Engineering, Department of

Building Structures,University of Technology by Brno.

References

1.

Künzel,H., Bestimmt der volumen- oder der massebezogeneFeuchegehalt

die Wärmeleitfähigkeit von Baustoffen,Bauphysik

8 (1986)

2.

Crank,J., The

Matematics of Diffusion, Oxford UniversityPress 1975, ISBN 0 19 853344 6

3. Cammerer,W.F., Die kapillare

Flüssigkeitsbewegung in porösen Körpern, 1963

3.

Gertis,K., Kiessl,K., Feuchtetransport in Baustoffen,Forschungsberichte aus

dem Fachbereich

Bauwesen, 1980

4.

Kutilek M. Dampness porous material, Czech Republic Prague SNTL, 1992

5.

Mrlík,

F. Building materials and construction

moisture problems, SR, Alfa Bratislava, 1985