Kraeva E.M.

Siberian State Aerospace University, Russia

À vortex zone in the channels of

high-speed

centrifugal pumps

High-speed

low-rate centrifugal pumps with rotor angular speed ![]() up to 10000 rad/s are

wide used in structures of turbo-pump units of liquid-propellant engine of low

traction and energy installation of aircrafts. That is because they have wide

range of operating conditions. E.g., if the rotor angular speed

up to 10000 rad/s are

wide used in structures of turbo-pump units of liquid-propellant engine of low

traction and energy installation of aircrafts. That is because they have wide

range of operating conditions. E.g., if the rotor angular speed ![]() rad/s, the value

rad/s, the value ![]() amounts to

amounts to ![]() under Reynolds number

under Reynolds number

![]() . The feed decreases in such pumps simultaneously with rotor

angular speed increase leads to

. The feed decreases in such pumps simultaneously with rotor

angular speed increase leads to ![]() decrease below value

decrease below value ![]() . It is rating value for closed-type impeller rotary pumps

[1]. Therefore high-speed rotary pumps with semiopen-type impeller are used

wide.

. It is rating value for closed-type impeller rotary pumps

[1]. Therefore high-speed rotary pumps with semiopen-type impeller are used

wide.

In

centrifugal impellers of semi-open and open types there is unevenness of flow

and vortex interaction along the radius of main fluid flow and in the lateral axil

of the pump. The vanes convey energy to the fluid flow, a portion of which is

moving with a lag from the main one in the lateral axil. In the result a flow

is formed as in the channel behind the bluff body. This flow is characterized

by the appearance of return currents and vortices. [2] This process is

determined by the ratio of width to length of the channel, the thickness of the

boundary layer on the walls and the relative height of the vane. The

interaction of flows in channels and axil leads to the appearance of

circulating currents in the area behind the vane.

Picture of

the flow between the rotating impeller with the end vanes and sleek hull is

quite complex. The liquid contained in the field of grooves is exposed to

direct power impact of the vanes. The fluid in the axial gap is twisted by the

forces of friction and slip relative to vanes of the impeller. Thus at the same

radius the particles of the fluid are moved with different speed in the

channels and the axial gap that causes a relative movement in the radial and

axial directions. In the area of vanes there is a radial expendable flow

towards the periphery.

Since the

coefficient of flow swirling φ <1, we always have a relative motion of

the fluid and the vanes of the impeller, that certainly leads to the formation

of circulation zone in the channels of the impeller as a result the flow wraps

around cavity.

One of the

characteristics of the vortex zone is the ratio of the circumferential speed ![]() to the incoming flow speed

to the incoming flow speed ![]() at the outer border of the vortex zone

at the outer border of the vortex zone

![]() (1)

(1)

The analytical calculation of the variable ![]() on the data of the work [2] for the channel of an impeller

gives the value

on the data of the work [2] for the channel of an impeller

gives the value ![]() . However,

the experimental data presented in the same paper indicate a significant

difference between the calculated value

. However,

the experimental data presented in the same paper indicate a significant

difference between the calculated value ![]() from

the experienced one, in the direction of increasing the experienced value. That

difference the author of [2] explains by the influence of boundary layers.

from

the experienced one, in the direction of increasing the experienced value. That

difference the author of [2] explains by the influence of boundary layers.

When testing a cylindrical fluid coupling on the water,

in [3] there is a marked clearly expressed vortex structures in cavities of the

rotating cylinder.

The analysis of experiments on determining the estimated

value ![]() , as described in this paper, gives us

a basis to take it to our research by 0.3.

, as described in this paper, gives us

a basis to take it to our research by 0.3.

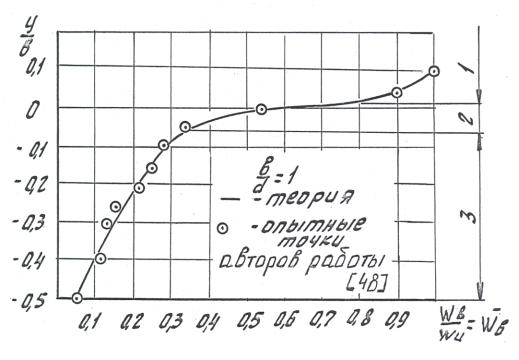

A typical picture of variation in flow speed through the

gap ![]() and the inter-vane channel (at a ratio of width to depth of the

channel

and the inter-vane channel (at a ratio of width to depth of the

channel ![]() ) (Figure 1) taking into account on

visualization tests confirmed the presence the three zones of flow: zone of the

flow 1 flowing over the channel; the mixing zone 2 and zone 3 of the circular

vortex flow in the channel region, where the speed

) (Figure 1) taking into account on

visualization tests confirmed the presence the three zones of flow: zone of the

flow 1 flowing over the channel; the mixing zone 2 and zone 3 of the circular

vortex flow in the channel region, where the speed ![]() .

.

Figure 1 – Experimental and theoretical profiles of

the circumferential speed in the channel region along the radius of the vortex

zone: 1 – the zone of the flow in the axial gap; 2 – the

mixing zone; 3 – the zone of the vortex flow;

![]() - experimental points [3]

- experimental points [3]

In order to clarify the main features of the hydrodynamics

in semi-open channels of an impeller, we conducted the series of experiments,

including those on the visualization of the flow in these impellers.

This work was supported by the grant of the President of

the Russian Federation ÌÊ – 1371.2013.8.

References

1. Kraev M.V., Lukin V.A., Ovsyannikov

B.V. Low-rate pumps of air and space system [in Russian], Mashinostroenie,

Moscow, 1985.

2. Abramovich G.N. The

theory of turbulent jets. – Ì. : Phismathgiz, 1960. – 716 p.

3. Levin À.À., Perelman R.G. Investigation

of a cylindrical fluid coupling / Investigation of

aggregates operating on alkaline metals: MAI. – 1969. – V.

193. – P. 57–102.