UIC 658.382

THE ANALYSES OF ACCUPATIONAL

INJURIES AND CERTIFICATION OF WORKPLACE ON WORK CONDITION AT THE LLP «TNS- INTEC»

Omirbay

R.S- doc. tecn. sci., Professor, Kazakh National Technical University

after K.I.Satpaev

Batesova

F.K. - сand.

tecn. sci., ass. Professor, Kazakh National Technical

University after K.I.Satpaev

Satybaldieva

N.K. - сand.

tecn. sci., ass. Professor, Kazakh National Technical

University after K.I.Satpaev

Toregeldi Zh. - the

magister of Kazakh National Technical University after K.I.Satpaev

Pirmanova

A.M., Pirzhanova G.I - the students of Kazakh National Technical University after

K.I.Satpaev

Abstract:

This scientific article of occupational injuries and diseases on LLP

«TNS-INTEC», where the certification of workplaces is under working conditions

in the production which carried out in order to implement health measures. As a

research problem has been identified by the authors estimate the risk of injury

jobs and work which matching the

requirements of health and safety on the results of certification at workplaces.

Keywords:

working conditions, occupational injuries, certification of workplaces, weight and intensity of work, injury

prevention.

The

Certification of Workplaces (CW) is under the terms of work on the production which figure out implementation of the improving actions,

acquaintance working with working conditions, certifications of production

objects and also for confirmation or cancellation of the right of providing compensations

and privileges to the workers which occupied on a hard work and works with

harmful and dangerous working conditions. Certification of working conditions

at work sites includes criteria as an

assessment of current conditions and the nature of work, assessment of injury

jobs and collateral personal protective equipment. Because of the certification at workplace is under the

terms of work all hazardous and harmful production factors which are available

on a workplace (physical, chemical, biological) [1], severity and intensity of work are subject to an

assessment. Each workplace is considered as one irrespective fact, which can be

changed one time or two time. According to the data of TNS-INTEC LLP we will

include the losses which connected with traumatism and diseases at the enterprise

for the period 2011-2014 year . in table 1.

Table

1. Traumatism and diseases at the enterprise

|

Name of basic data |

unit |

2011 |

2012 |

2013 |

2014 |

Absolute change |

Growth rate |

|

Total list number of the working |

person |

380 |

450 |

581 |

743 |

92 |

90 |

|

Annual fund of calendar working hours |

days |

260 |

260 |

260 |

260 |

- |

- |

|

It is lost by all injured |

days |

178 |

187 |

146 |

129 |

79 |

51 |

|

It is lost by all patients |

hour |

3526 |

3652 |

3753 |

3888 |

135 |

104 |

|

Number of the injured |

Person |

1 |

2 |

2 |

3 |

-1 |

67 |

|

Number of employee who does not working as a

result of diseases |

person |

135 |

143 |

140 |

145 |

5 |

104 |

|

Average day actual development for 1 slave. |

tg |

1985 |

2225 |

2455 |

3683 |

1228 |

15 |

|

Daily average payment on/l, connected from

injuries. |

tg |

322,1 |

342,2 |

365,2 |

515,4 |

37,2 |

139 |

|

Daily average payment on/l, connected with

diseases |

tg |

196,8 |

221,2 |

241,2 |

365,3 |

19,1 |

131 |

|

It is spent funds for improvement of

conditions |

tg |

2314 |

2325 |

2405 |

2524 |

28 |

105 |

|

Duration of the working day |

hour |

7,9 |

7,9 |

7,9 |

7,93 |

0,03 |

100 |

|

The cost of all made production in a year |

Thou-sand tg |

278522 |

271452 |

286414 |

404862 |

72218 |

195 |

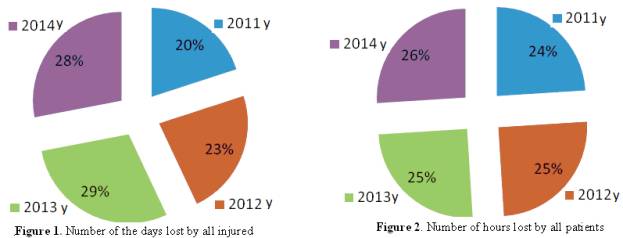

The

data in Table 1 show that the number of days lost all injured decreased by 17

days compared to 2013 year, the number of injured in 2014 decreased by 1 person

compared to the previous year, due to the fact that the company pays great

attention to training in health and safety. Number is not working as a result

of the disease has increased by 5 people in 2014 compared to 2013godom. And the

percentage of them which has shown in Figures 1 - 4. Average daily payment for

sick leave related injuries also increased in 2014 to 150 n., and the average

daily payment associated with the disease increased slightly, to 124tg .. Funds

for improvement working conditions are small, but in 2014 they spent more on

119 tg. compared to 2013. In general, we see that the losses associated with

injuries and illnesses in small enterprises, and therefore the company in the

face of the head, meets the requirements of health and safety [2] and following

the injury and illness of workers. The data are taken into accounting

department of occupational safety, the engineers on safety in the planning and

economic department. In order to calculate the losses associated with injuries,

we use the following documents: statements about the salary, sick leave,

accident reports. The data for the calculation are reduced in table 2.

Table

2. The exponent injuries

|

The name of indicators |

unit |

designation |

2011 |

2012 |

2013 |

2014 |

absolute change |

growth rate |

|

The number of accidents |

unit |

Nт |

3 |

2 |

2 |

2 |

-1 |

66 |

|

The number of days of disability |

Dn. |

Дт |

192 |

172 |

158 |

78 |

-114 |

41 |

|

Injury frequency rate |

unit. |

Пч=Nт/Жр*1000 |

6,7 |

4,3 |

3,4 |

3,4 |

-3,3 |

51 |

|

Rate of disability |

Dn.

Per 1000 people |

Пч=Дт/Жр*1000 |

427 |

370 |

336 |

134 |

-293 |

31 |

|

Injury severity index |

Dn |

Пт=Дт/Nт |

64,0 |

86,0 |

79,0 |

39 |

-25 |

61 |

|

Number of occupational diseases |

unit. |

- |

|

- |

- |

|

- |

- |

On the

basis of data (table 2) it is visible that traumatism for the last year goes to

TNS-INTEC LLP to decrease, in 2014 in the first case occurred less, than in 2011 it means that the security

service of work attend special attention to training on labor protection and

safety measures, reduction of number of accidents leads a consequence to

decrease in number of disabled days, so and decrease in an indicator of

disability which decreased for 293 days for 2014. The 427th day, and in

2014-134 days fell on 1000 people in 2011 year. That it is possible to tell and

about weight of traumatism which in recent years decreased from 64 to 39 days.

The indicator of disability of traumatism decreased for the last year three times.

It means that from 1000 disabled days in 2014 gave consequences of traumatism

to less 134 the working days. In general we see that all indicators of

traumatism is falling down, it is

connected with that at the enterprise improvement of workplaces is conducted,

the special attention to training and labor protection and safety measures with

workers is paid, defects of the equipment which consequences could lead to

injuries are eliminated. Extent of damage from injuries in 2011 totaled 930 820

n., And in 2014 fell to 320 970 n., The decline was due to reducing the number

of working days lost all the injured, as well as increasing the average output

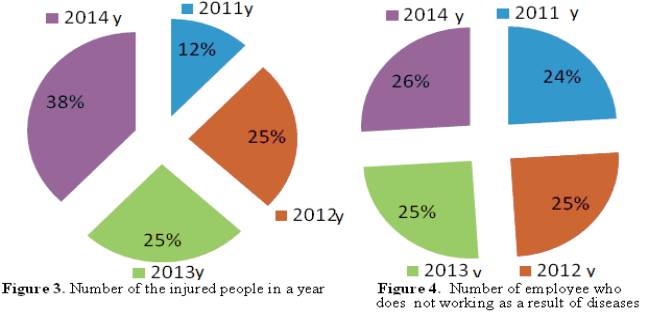

per worker .Certification of workplaces was figure out on 343 jobs on schedule, according to the

order on the establishment of a permanent commission for certification of

workplaces on working conditions in the LLP «TNS-INTEC»According to the results

of certification of 69 jobs (PM) comply with occupational health and safety

(GiOT) [3] refer to 1-2 hazard class, ie, not hazardous and moderately

hazardous 280 jobs are conditionally certified, ie belong to the class 3 (risk)

to 3.1. - 98 jobs, which employ 390 people, to 3.2. - 89 jobs, which employ 443

people, to 3.3. - 61 jobs, which employ 182 people, to 3.4 - 32 jobs, which

employ 82 people. All these data indicated above as a percentage is shown in

Figures 5 and 6.

Figure 5. Distribution of labour

workplace.

Figure 6.

Distribution of the PM does not meet the requirements for the

degree GiOT harm and danger

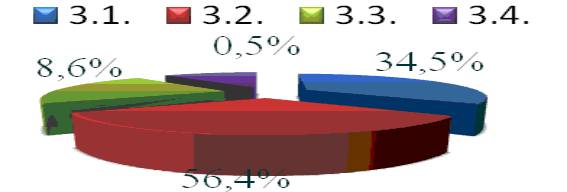

Assessment

of the risk of injury of jobs held by checking the corresponding production

equipment, appliances and tools, as well as training facilities and coaching

requirements of normative legal acts. Of 343 jobs 48 workers belong to a class

of 3- dangerous (Figure 7).

Figure 7.

Distribution of traumatic PM to total PM

Providing

employees working clothes and foot shoes

company is conducted in accordance with the model rules of free issue of

certified special clothing [4], footwear and other personal protective

equipment to employees engaged in work with harmful and (or) dangerous working

conditions. Providing jobs with personal protective equipment complies with

occupational safety and health [5].Thus, after analyzing the following

activities are proposed to reduce occupational injuries:- Pay attention to

training in the field of protection and safety specialists of the company, and

send them to seminars and training courses; - Provide posters, labels, safety

signs and other visual aids for the protection of health and safety; - On the

possibility of recruiting professionals with the appropriate profile education;

- Provide sufficient number of items protection and proper use of them in

production; - Strengthen the monitoring of briefings at the workplace; - Timely

monitoring of the serviceability of the equipment; - Control the use and

training of the correct use of personal protective equipment.

The literature

1 Постановление

Правительства РК от 05.12.2011 года № 1457

"Об утверждении порядка проведения аттестации рабочих мест по условиям

труда»;

2 Постановление

Правительства Республики Казахстан от 21 августа 2007 года № 721 "Об утверждении Правил

принятия нормативных правовых актов в области безопасности и охраны труда

соответствующими уполномоченными органами".

3 Трудовой Кодекс Республики Казахстан от 19.07.2013г.

4 Санитарные правила №1430 от 01.12.2011г. «Санитарно-эпидемиологические

требования к условиям работы с

источниками физических факторов (компьютеры и видеотерминалы), оказывающие

воздействию на человека

5 ГОСТ

РК 12.4.233-2007 ССБТ. Средства индивидуальной защиты органов дыхания