Engineering science / 8. Processing of

materials in mechanical engineering.

Postgraduate Konkina V.V. , Candidate of Engineering Sciences Solovjev D.S., Eryshova A.S.

Tambov State Technical University, Russia

OPTIMIZATION

OF PROCESS CONTROL OF REVERSE MODE ELECTROPLATING IN MULTI ANODE BATH

One of the main objectives of automation of

galvanic processes is obtaining uniform plating. According to the authors, an

implementation of reverse mode in multi anode bath is the most promising method

of reducing the nonuniformity of electrolytic plating. Nevertheless, the implementation

would be ineffective without developing algorithms of the process control for

such method.

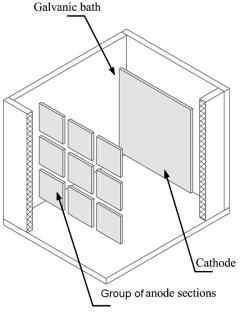

In the proposed process, a monolithic anode (fig. 1a) divides into a group of equal sized sections with density MxN,

which are placed in one plane at equal distance from each other, as well as

from walls of bath and in front of cathode product (fig. 1b – a group of 3x3 anode

sections). Such group of sections connect to a programmable power supply via a device

which can turn off the required anode sections. This connection enables to establish

either "direct" or "reverse" mode of current reversal in

order to reduce the nonuniformity of electrolytic plating due to the fact that

during the course of "direct" and "reverse" current the speed of cathode metal coating dissolution is

faster on surfaces that nearer to the anode sections, rather than on those

which are far from them.

The mathematical formulation of the problem of the optimal process

control is as follows: find arrays of active anode sections for

"direct" ![]() and "reverse"

and "reverse" ![]() mode of electroplating process reversal, as well as the duration

mode of electroplating process reversal, as well as the duration ![]() ,

, ![]() of such phases, which

minimize the criterion of nonuniformity of the thickness of the coating on

the cathode surface Sk:

of such phases, which

minimize the criterion of nonuniformity of the thickness of the coating on

the cathode surface Sk:

, (1)

, (1)

the following restrictions

must be carried out:

![]() , (2)

, (2)

![]() (3)

(3)

where ![]() – the given thickness of plating;

– the given thickness of plating; ![]() – the minimum thickness of the plating;

– the minimum thickness of the plating; ![]() – the maximum thickness of the plating; Ò – the duration of

electroplating process; Òmax – the maximum length of electroplating process;

x, y, z – coordinates of a point in the

space of the plating bath; υ – a number of

phases of switching on the "direct" and

"reverse" current.

– the maximum thickness of the plating; Ò – the duration of

electroplating process; Òmax – the maximum length of electroplating process;

x, y, z – coordinates of a point in the

space of the plating bath; υ – a number of

phases of switching on the "direct" and

"reverse" current.

|

(a) |

(b) |

Fig. 1. Structural scheme of galvanic bath with monolithic anode (a) and a group of 3õ3 anode sections (b)

In the work [1] a mathematical model, containing

Faraday's law, Ohm’s law in differential form, as well as the Laplace’s

differential equation in partial derivatives, is being proposed for the above-described

process.

The objective of finding the optimal process

control of proposed method represents a partially integer objective of a binary

nonlinear programming. On the assumption of the well-known drawbacks of the existing approaches to the solution of integer programming problems (branch and bound methods,

combinatorial problems), the authors have chosen the method of an exhaustive search to find the optimal

configuration for a group of active anode sections in "direct" or

"reverse" mode of current reversal, where pattern-search method, by

Hooke-Jeeves, has been used to find durations of duty cycles [2].

After specifying the dimensionality of the group of

anode sections and its configuration, as well as the geometry of cathode product,

restrictions on the values of the minimum specified thickness of the coating (2)

and process duration (3) two cycles begin: cycles on the formation of arrays of

active anode sections in "direct" or "reverse" mode of electroplating process. The number of iterations in each cycle is 2M∙N times, which is

explained by the possibility of taking only binary values for the array

elements. At the same time the selection of durations τdir and τrev is carried out

according to the selected algorithm. After calculating all the values of

criteria of non-uniformity, optimal process control actions are selected to

ensure its minimum (1).

References:

1.

Konkina V.V., Solovjev D.S. Matematicheskaya

postanovka zadachi optimalnogo upravleniya galvanicheskim protsessom v

reversivnom rezhime dlya mnogoanodnoy vannyi

[Mathematical formulation

of the problem of optimal control of electroplating process in reverse

mode for multianode bath] // Teoreticheskie

i prakticheskie aspektyi tehnicheskih nauk: sb. statey mezhdunar. nauch.-prakt.

konf. – Ufa: «Aeterna». 2014. pp. 41 – 43.

2.

Konkina V.V., Solovjev D.S. Mathematical modelling of electroplating in

reverse mode for the multianode bath. ISJ Theoretical & Applied Science.

2015. vol. 03, no 23. pp. 59 – 62.