technical

/ metallurgy

Candidate of Physical and Mathematical Sciences

Mukhtarova M.N., Nurseytova

A.K., Ermaganbetova S. D.

Al-Farabi Kazakh National University

Almaty, Kazakhstan

The concept and ways of its realization

Currently, the following areas are defined

creating waste-free (and low-waste) production:

-

development of new technological schemes and methods of industrial production,

excluding the release of waste into the environment;

-

Creation of closed technological schemes of water reuse and process gases;

-

The creation of waste management system of production, which are considered as

secondary material resources, the organization of large regional

territorial-industrial complexes of the closed structure of the feed streams to

deep processing.

Work

on the latest trend began in the 80s and took thirty years.As a result, not

only the new concept of deep processing of non-waste technological fields were

managed, but also developing methods and technical means for its

implementation. Proposed currently processing complex today includes the

proven, unique, having no analogues in the world equipment.

We

are convinced that it is time to centralized implementation and replication

technologies for deep waste-free development of natural and man-made deposits

autonomous mobile complexes with extraction of useful components and dumping

(conservation) of harmful components (-toxicants elements), followed by

reclamation and return into the economy liberated from their territories.

Methods

of designing systems to adapt the technology of deep-waste recycling in terms

of virtually any known technogeneticdeposits, including deep processing of

sludge storage tanks coal preparation plants to produce finely

dispersedcoal-water and briquetted fuel, building material and fertilizer, as

well as their use in the cement industry in the production of chalky-clay

sludge and many other products.

In

assessing the ecological status of the ore district chemical composition of the

tailings ferruginous quartzite field has been studied. Ecological and

geochemical characteristics of tailings ferruginous quartzite are presented in

Table 1. The data obtained are compared with an average content of chemical elements

in the lithosphere and the list above the Clarke us elements (in descending

order of concentration ratios).

With

regard to natural radionuclides, the comparative analysis of their distribution

in the tailings and source ferruginous quartzites showed that tails depleted

thorium (Th) of 3.5 times, uranium (U) to 1.3 times, i.e., these radionuclides

"enrich" iron ore concentrate and follow further along the process

chain up to the metallurgical processing. The chemical composition of coal

sludge storage tanks present similar elements with their different content,

depending on the genesis of deposits.

As

a result of investigations to solve the most acute problems of cleaning

territories from man-made pollution and the associated extraction of mineral

and toxic components of the technology of working out of man-made and natural

and man-made deposits via mobile technological complexes on the basis of

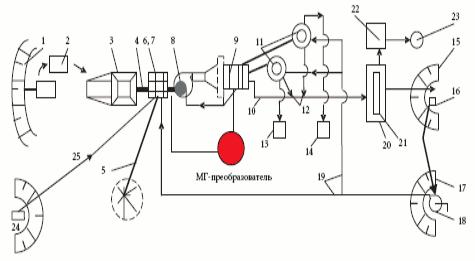

original technical solutions (Fig. 1).

Fig.

1 Autonomous Driving Mobile technological complex circuit devices for recycling

and disposal man-made and natural technogenic deposits

Technological

complex for deep processing of technogenic raw materials with the extraction of

valuable components (gold, platinum, palladium, silver, non-magnetic

iron-hematite and others.) and the removal of harmful impurities (containing

mercury and heavy metals, radionuclides) from the tails of enrichment plants of

non-ferrous and ferrous metallurgy. All of these components and waste without

metal (tailings) are quite valuable products for the

metallurgical, construction, part of

jewelry and other industries and the economy as a whole .

Thus,

the proposed technology for processing technogenic waste (tailings, Ephel,

sludge storage tanks) allows removal and disposal of harmful impurities,

including in underground spaces developed after their preliminary condensation,

which is also ensured by technical means that are part of the complex. The

proposed technology provides a cost-effective and environmentally friendly and

virtually waste-free production with significantly lower cost of operating the

main products of mining and processing of non-ferrous and ferrous metallurgy in

Kazakhstan.

Literature:

1. Vinogradov NF, "Nature." - M., 1994.

2. Kikava O.Sh. etc. "Construction materials from production waste."

- "Ecology and Industry of Russia», 12, 1997.

3.

Protasov VF, Molchanov AV "Environment, health

and environmental management in Russia" - Moscow, "Finance and

Statistics", 1995.

4. "Ecology". Textbook, Ed. S.A.Bogolyubova - M.,

"Knowledge", 1997.