Technical Sciences / 8. Metal Treatment in Machine-Building

Doctor of Technical Sciences, Professor Boldyrev À.I.,

Candidate of Technical Sciences Boldyrev A.A.

Voronezh State Technical University, Russia

Design of Combined Processing

Techniques

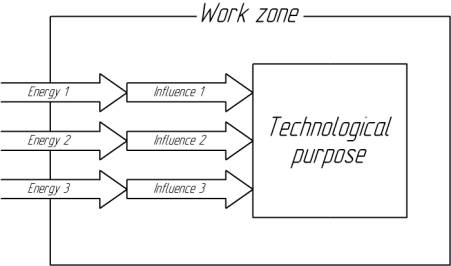

The main

difference of combined processing techniques from other methods is uniting

different means of exposure on workpiece material in one shaping process. Implementation

of similar methods requires combined application of two or more kinds of

energy. They should be brought to working zone and used for attaining of

desired technological goals (Fig. 1).

Figure 1. Graphic

model of combined processing technique

The

conducted research showed that choice of concrete method of combined treatment

and kinds of energy, brought to working zone allows step-by-step determination

of energy supply method, working zone for treatment, static, kinematic, and

dynamic shaping schemes, sources of power and king of machining tool.

At the

same time the main purpose of combining different methods of exposure and kinds

of supplied energy in one technique is intensification of shaping, acceleration

of rough tolerances removal and formation of workpiece surfaces with desired

accurate and physical and mechanical properties. That is why not every combination

of exposure methods and supplied sources of energy is executable or rational.

Conditions

for compatibility of main components of combined processing techniques in one

process were defined due to study of characteristics of exposure methods on

workpiece material and kinds of energy required for shaping.

Method

of exposure on workpiece material is crucial component of any processing

technique. Method of exposure is completely specified if values of its main

properties are given: shaping method, physical process of dimensional shaping,

kind of shaping energy, physical state of workpiece material removed during

processing, storage density, specific modified material volume, attainable

accuracy and processing roughness, kind and depth of change in workpiece

surface layer, mark of internal stresses of changed workpiece layer, wear ratio

of machining tool.

There

are specific dependences between different properties of exposure methods. In

particular shaping method is determinates physical shaping process. The

physical shaping process determinates shaping energy brought to processing zone

and physical state of workpiece material removed during shaping. Permissible

values combinations for main properties of exposure methods are presented in table

1.

Table 1

Permissible values

combinations for main properties of exposure methods

|

Shaping method |

Physical shaping process |

Energy of shaping |

Physical state of workpiece

material removed during shaping |

|

Rough tolerance removal |

Evaporation |

|

Vapor |

|

Melting and evaporation |

|||

|

Plastic deformation with

fracture |

Mechanical |

Solid, Solid disperse |

|

|

Brittle fracture |

Initial |

||

|

Chemical dissolution |

Chemical |

In liquid solution |

|

|

Change of state between

points of solid body |

Plastic deformation without

fracture |

Mechanical |

No removed metal |

|

Change of workpiece

aggregative state |

Evaporation |

Thermal |

Vapor |

|

Melting and evaporation |

In melt |

||

|

Melting, solidification, crystallization |

No removed metal |

||

|

Directed particle joining |

Electrolysis of solutions or

melts |

Chemical |

No removed metal |

|

Crystallization from

solutions, melts and vapors |

|||

|

Directed interaction of

electrified and magnetized particles |

|||

|

Interaction of dispersed

particles and joining material |

Practice

shows that of all kinds of energy that may be brought to processing zone

(thermal, mechanical, electrical, magnetic, chemical, radiation, nuclear) only

thermal, mechanical, and chemical are used today directly for technological

purposes. Other kinds of energy need transformation for application during processing.

Possible variants of energy transformation are presented in table 2.

Data

from table 2 allows finding correspondence between kind of energy brought to

processing zone and kind of shaping energy (table 3).

Table 2

Possible variants of energy transformation

|

Initial energy |

Transformed energy |

|

Thermal |

Mechanical |

|

Mechanical |

Thermal, electrical |

|

Electrical |

Thermal, mechanical, magnetic, chemical, radiation |

|

Magnetic |

Mechanical, electrical |

|

Chemical |

Thermal, electrical, mechanical |

|

Radiation |

Thermal, electrical, chemical |

|

Nuclear |

Thermal, mechanical, magnetic, radiation |

Table 3

Correspondence

between kind of supplied energy and kind of shaping energy

|

Energy brought to processing

zone |

Conditions of energy supply |

Shaping energy |

|

Thermal |

Without transformation |

Thermal |

|

Mechanical Electrical Chemical Radiation Nuclear |

With transformation |

|

|

Mechanical |

Without transformation |

Mechanical |

|

Thermal Electrical Magnetic Nuclear |

With transformation |

|

|

Chemical |

Without transformation |

Chemical |

|

Electrical Radiation |

With transformation |

Due to data

from tables 2 and 3 main properties of processing method component “kind of

energy brought to processing zone” were defined. Among them are: kind of

initial energy, kind of transformed energy, conditions of energy supply, shaping

energy.

Knowledge

on properties of processing method components, possible and permissible value

combinations of these properties allows organizing generation of new shaping

methods. At the same time necessary combination of processing method components

is reached due to analysis of community and relation of their properties. So it

is reasonable to suppose that if two components have at least one common

property than there is a connection between them based on community of

properties. By analogy if there is a determined functional relation between

different properties of two components than there is mutual relation of

properties between these components.

Such

approach allows structuring the whole topical area of combined processing

techniques and organizing purposeful synthesis of new shaping methods.