Detonation characteristics of low-density emulsion explosives sensitized

with polystyrene Foam beads, and their applicability in PERIMETER blasting at

quarries

S.A.

Gorinov

Global Mining Explosive-Russia LLC, Moscow

I.Y. Maslov

Global Mining Explosive-Russia LLC, Moscow

ABSTRACT: It was demonstrated that stable propagation of

explosive process is possible in low-density emulsion explosives obtained

through mixing of emulsion with a significant amount of polystyrene foam (or

other similar) beads. Such process takes place in the form of a detonation-like

wave of emulsion drops combustion in explosive gas streams flowing out of the

high-pressure area of the reaction zone.

Chemical reaction

in such EEs (emulsion explosives) takes places takes place in the form of

surface combustion of emulsion particles interacting with the gas stream.

A method was

developed for determining parameters of decomposition of low-density EEs, and

it was demonstrated that gradual pressure increase takes place in products of

explosive’s decomposition during explosion of such EEs.

Analytical criteria

were obtained for evaluation of propagation stability of this process.

These findings

allow obtaining practically useful results for validation of gentle blasting

technology with the use of low-density EEs.

1. TIMELINESS OF THE STUDY

The use of low-density emulsion explosives sensitized with porous beads

of materials having acoustic stiffness close to the acoustic stiffness of

emulsion (e.g. polystyrene foam beads) may become one of the promising

directions for highly mechanized gentle blasting operations in open cast

mining. Such EEs are not much exposed to shrinkage under hydrostatic pressure

(within the range of charge height of 30-40 meters) [1]. Low densities of such

explosives allow for the efficient use of continuous explosive columns in

gentle blasting [2], which in turn provides a high degree of mechanization of

charging operations.

Previous studies [1,3] have shown that in case the densities of the

examined EEs are higher than 0.75 g/cm3 (for EEs with ammonium

nitrate oxidation phase), initiation of explosives takes place due to heating

of the matrix emulsion matter during its inflow into surface pores of

polystyrene foam beads under the pressure in detonation front.

In case the densities of the EEs sensitized with polystyrene foam beads

are less than 0.75 g/cm3 (for EEs with ammonium nitrate oxidation phase),

deviations were noticed between calculated and experimental values of velocity

of detonation (VOD) [1].

In order to explain the deviations between the calculated value and the

experimental value of VOD at the density of the polystyrene foam sensitized

emulsion explosive less than 0.75 g/cm3 (for EEs with ammonium

nitrate oxidation phase), the following hypothesis was suggested:

a) in case the EE

under study has low density, a connected “polystyrene foam beads – air pores”

system appears within the EE;

b) presence of

end-to-end channels changes the EE’s initiation mechanism. In this case,

initiation will take place according to the mechanism described in study [4] –

under the action of high-enthalpy gas stream filtering from the area of high

pressure. At that, chemical reaction takes place in the form of surface

combustion of explosive particles interacting with the gas stream.

2. STUDY MATERIALS AND RESULTS

In order to validate these provisions, experimental and theoretical

researches were performed.

As a part of field research, experiments were carried out on measuring completeness

and velocity of detonation in the process of blasting of open cylindrical

charges of the examined EE in cardboard tubes (shells). Shells were made of 1mm

thick sheets of laminated electrical cardboard, which were winded in three laps

onto the previously prepared cylindrical templates. VOD Mate (Instantel) and

HandyTrap (MREL) hardware continuously measuring the resistance value of the

conducting sensor’s electrical circuit was used for measuring VOD. Conducting

sensor was glued onto to the cardboard sheet before winding onto the template.

After winding onto the template, cardboard sheets were fixed with a scotch

tape. After template extraction, one of the ends of the resulting tube was

filled with Markoflex polyurethane foam, and after that the shell took its

final form (the “plug” of the solidified PU foam was preventing the Emulpor

from flowing out of the shell; a shell like this can be easily moved across the

field). The shell’s length was not less than 1000 mm, the length of the

chargeable (with EE) part of the shell – not less than 900 mm.

Let’s take an in-depth look at one of the series of experiments.

The emulsion of the following chemical composition was used to create

the EE: NH4NO3 – 75.0% of the total mass, H2O

- 18% of the total mass, emulsifier – 1.0% of the total mass, machine oil –

6.0% of the total mass. The emulsion's density at this chemical composition was

1328 kg/m3 (based on laboratory measurements).

In order to sensitize the above-mentioned emulsion, popcorn beads of 40

kg/m3 bulk density and

8.0mm average diameter were used (these beads have porosity and mechanical

characteristics that are close to such of the polystyrene foam of similar bulk

density). The EE was prepared by mixing of emulsion (EM) with popcorn beads

(PPC) at volume ratio: 7 EM and 4 PPC. Mixture density was 600 kg/m3.

Let’s introduce some designations:

ψ - ratio of the

bulk volume of popcorn beads to the volume of matrix emulsion;

ρ00 - density of the

EE sensitized with popcorn beads;

ρem - matrix emulsion density;

ρppc - bulk density of popcorn beads.

In the case under study, ψ =1.75; ρ00 = 600 kg/m3; ρem = 1328 kg/m3; ρppc = 40 kg/m3.

According to [5], if condition

(1) is true, then a connected “sen›sitizing beads – air pores” system appears

within the EE, and the explosive under study has “foggy” structure consisting

of matrix emulsion drops, which are separated from each other by air pockets

and (or) light, fragile beads.

Packing factor of popcorn

beads was defined through laboratory research and amounted to kpack = 1.6.

After inserting the given

parameter values in (1), we get 0.089 > 0.

Thus, the EE in the series of

experiments under study had “foggy” structure consisting of matrix emulsion

drops separated from each other by air pockets and (or) light, fragile beads of

the material having acoustic stiffness close to the acoustic stiffness of the

matrix emulsion.

The external appearance of

experimental charge in a cardboard shell of 130 mm diameter is shown in Figure

1.

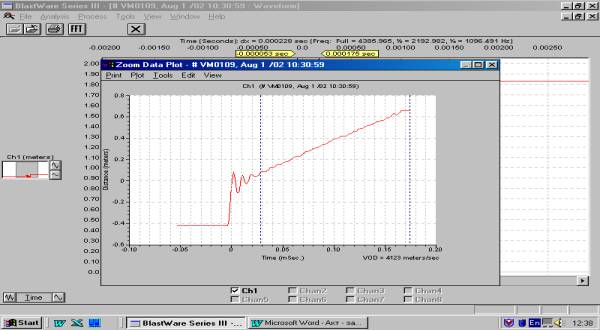

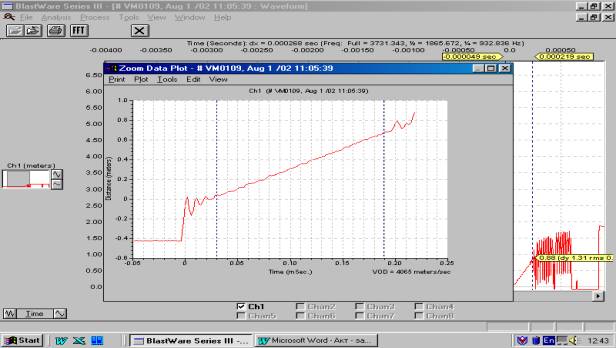

As the result of experiments,

it was determined that when the composition is initiated by boosters made of

T-1000-L-PO trinitrotoluene blocks, it detonates completely. At that, VOD

amounts to 4123 m/s when blasting 240 mm diameter charge (Figure 2), and to

4065 m/s when charge diameter is 130 mm (Figure 3).

Figure 1. External appearance of experimental

charge in a cardboard shell of 130 mm diameter

Figure 2. Time variation of the distance covered by the detonation wave

Charge diameter – 240 mm. VOD =

4123 m/s. Booster – T-1000-L-P block

Figure 3. Time variation of the distance

covered by the detonation wave

Charge diameter – 130 mm. VOD =

4065 m/s. Booster –T-1000-L-P block

3. DISCUSSION OF EXPERIMENTAL DATA

Let us assume that detonation processes are described by a model that was

offered in studies [6-9] for description of detonation of industrial ammonium

nitrate explosives. Such model was chosen because it considers the fact that no

instant decomposition of explosive takes place during propagation of detonation

wave within the above-specified explosives. During the initial period,

compression of the explosive takes place under the action of detonation wave as

a result of pore space filling with the explosive, then the explosive is heated

due to internal friction and heat of gases in the pore space, and only then the

explosive ignites. At that, the model considers the fact that the medium acquires

additional velocity during compression along the direction of the detonation

wave propagation, which allows us to explain a number of previously

incomprehensible kinematic effects during propagation of detonation in ammonium

nitrate explosives [6].

Within the scope of the assumed model for description of detonation

process, we have:

according to the energy conservation law, assuming incompressibility of

solid reaction products (within the scope of two-polytropic model for

description of detonation products expansion):

where ![]() is the relative molar heat capacity of

explosion products;

is the relative molar heat capacity of

explosion products;

k is the factor of

polytropic curve of explosion products;

γ is the factor of

adiabatic curve of explosive gases;

![]() is the total part

of solid matter in explosion products;

is the total part

of solid matter in explosion products;

![]() is the total relative volume

of solid explosion products;

is the total relative volume

of solid explosion products;

ρ0gas is the density of gaseous explosion products

at the beginning of EE decomposition;

K+ is a parameter representing the volume of

gaseous explosion products in the conjunction point in case of two-polytropic

description P=P(V) of gaseous explosion products (based on processing of

empirical data, K+»4.4 [6]);

u is the velocity increment of

moving explosion products in the detonation front;

ρ0 = kp ρ00 is the density of the explosive at the beginning of

decomposition (kp is the compression

factor of the explosive at the beginning of its decomposition);

Qv is the specific

heat of reaction;

cv is the specific

heat capacity of explosion products;

α is the covolume of

explosion products (acc. to Vlasov);

Initial density of gaseous explosion products:

(3)

(3)

![]() value is determined

under the momentum conservation law, and in this case, it approximately equals

to:

value is determined

under the momentum conservation law, and in this case, it approximately equals

to: ![]() (4)

(4)

Explosion gases state equation

(5)

(5)

Velocity of detonation![]() (in coordinate

system moving along the direction of the process with

(in coordinate

system moving along the direction of the process with![]() speed) equals to:

speed) equals to:

(6)

(6)

The measured VOD (velocity of detonation in the laboratory system of

coordinates) equals to:

![]() (7)

(7)

The system of equations

(2)-(5) can be solved if the value of compression factor kp is known.

In our case, kp evaluation was

performed through extrapolation of calculated kp values for the

range of Emulpor densities 1.0-1.27 g/cm3 (kp was calculated by

the procedure described in studies [1,3]) to the area of low charge densities.

The extrapolation curve is shown in Figure 4. Based on the acquired results, we

took

kp ≈ 1.45 –

0.37ρ00 for evaluative

calculations, where ρ00 was taken in g/cm3.

At ρii = 0.6 g/cm3, kp = 1.23.

The results of VOD

calculation through the above-given equations for the series of experiments

under study:

![]() = 3195 m/s (D = 2622 m/s; u = 572 m/s).

= 3195 m/s (D = 2622 m/s; u = 572 m/s).

The calculated value is significantly lower than the experimental value.

Thus, the assumption that detonative

decomposition of the EE under study takes place due to the internal friction in

the process of pore space filling and due to the heat of gases in the

compressing pores doesn’t allow us to explain such high VOD values at such a

low EE density.

Hence, another concept is necessary in order

to explain the observed VOD values.

In accordance with (1), there is a connected bead-air system in the

low-density EE under study. Let us assume that initiation of detonation in this

EE will take place in accordance with the explosive initiation mechanism

described in study [4].

In this case, initiation of

the mentioned EE will take place under the action of high-enthalpy gas stream

filtering from the area of high pressure. At that, chemical reaction takes

place in the form of surface combustion of explosive particles interacting with

the gas stream.

Let’s determine the parameters

of the filtering stream of explosive gases from the area of high pressure.

Let’s introduce the following designations:

![]() - stream speed with respect to

a stationary observer;

- stream speed with respect to

a stationary observer;

ρf , Tf - density and temperature of explosive gases

in the head end of the stream of explosive gases flowing out from the area of

high pressure;

ρx , Tx - density and temperature of air in the head

end of the air blast wave generated by the stream of explosive gases.

![]()

![]()

Figure 4. Compression factor of the EE sensitized with polystyrene foam

beads as a function of the EE’s density (extrapolation).

In terms of gas dynamic

relations [10], within the scope of two-polytropic model of explosive gases

expansion, we have the following equations for determination of parameters of

the explosive gas stream filtering from the area of high pressure:

where γa =1.2 is the adiabatic exponent

of air in the blast wave;

TB is the temperature of explosion products.

The stream of explosive gases

flowing out from the area of high pressure generates a blast wave in the air

that is between the beads and inside them (porosity is 95-98%). This blast wave

and the following stream of hot explosive gases flow around the drops of matrix

emulsion “fog”. If these drops inflame during the period less than the duration

of explosion decomposition process in the area of violent chemical reaction

(the area of high pressure), then propagation of the explosive process

throughout the low-density EE will be determined by the propagation speed of

this ignition process.

We shall evaluate the ignition

time of emulsion drops according to study [11].

Induction time τ of ignition of an emulsion drop (when it is

blown over by the air blast wave and the stream of explosive gases) will be

found from the following equations (we assume that due to exceptionally short

duration of ignition process, radiant energy plays the leading role in its

realization):

![]() (11)

(11)

where ![]() is the temperature difference;

is the temperature difference;

![]() - the “reaction

speed – temperature” correlation index; TH - the initial temperature of emulsion; TS - the temperature

of an emulsion drop’s surface, when it is blown over by the air blast wave and

the stream of explosive gases;

- the “reaction

speed – temperature” correlation index; TH - the initial temperature of emulsion; TS - the temperature

of an emulsion drop’s surface, when it is blown over by the air blast wave and

the stream of explosive gases; ![]() - activation energy; z - pre-exponential

factor; c - specific heat

capacity of the matrix emulsion; R - universal gas constant.

- activation energy; z - pre-exponential

factor; c - specific heat

capacity of the matrix emulsion; R - universal gas constant.

We determine the temperature

of an emulsion drop’s surface with regard for deceleration of the blast wave

and the explosive gas stream, and for thermal activity of substances that take

part in heat transfer process [12]:

where ![]() are factors of thermal activity of

(correspondingly) air in the blast wave, and the stream of explosive gases with

relation to the emulsion matter:

are factors of thermal activity of

(correspondingly) air in the blast wave, and the stream of explosive gases with

relation to the emulsion matter:

![]()

λ1 , cair , ρx - heat conductivity factor, heat capacity and

density of air (in the blast wave);

λ2 , cstream , ρf - heat conductivity factor, heat capacity

and density of explosive gases in the stream’s head end;

λe , ce , ρe - heat conductivity factor, heat capacity and

density of the emulsion;

Tbl.w. - temperature of

air in the blast wave (it is found from the solutions of [10]).

The condition for

occurrence of detonation transmission by the streams of explosive gases flowing

out from the area of high pressure will take place in case

τ < tchem.r. ,

(14)

where tchem.r. - duration time of

chemical reaction in the area of high pressure.

In the case under

consideration

![]() (15)

(15)

where Rdr is the average

radius of an emulsion drop; vcomb. - the velocity of ablation

combustion.

The velocity of

ablation combustion is determined with reference to the data from [4]:

(16)

(16)

The resulting

relations (8)-(10) allow us to evaluate the propagation speed of the detonation-like

process, and equations (11)-(16) allow to evaluate the possibility of process

transmission by the streams of explosive gases flowing out from the area of

high pressure. However, it is necessary to consider the stability of this

phenomenon.

According to V.S.

Trofimov, detonation process will not be disrupted due to pressure drop in the

discharging wave following after the chemical reaction zone if the condition

[13] is true:

![]() (17)

(17)

ς - the part of the

reacted EE matter;

v - specific

volume;

![]() - density of

explosion products in Chapman-Jouguet point;

- density of

explosion products in Chapman-Jouguet point;

θ - the factor of thermal expansion of explosion products

in the reaction zone;

Based on transformation of

thermodynamic relations [14], it may be shown that

![]() (18)

(18)

Let’s substitute (18) into

(17) and take integral. As the result, we get the following condition of

absence of detonation process disruption:

![]() (19)

(19)

In accordance with

[15], the state of detonation products in the area of violent chemical reaction

approaches to liquid properties. Due to the absence of experimental data for θ, this value has been determined according to

the formula [16,17]

![]() (20)

(20)

where μ is Poisson ratio (in this case, μ = 0.5); Csound - sound velocity in

explosion products in the reaction zone.

On the basis of (6), (19),

(20), we get the following criterion of absence of detonation disruption:

(21)

(21)

In rough figures, we have the

following expressions for some parameters that are included in (21):

On the basis of (21)-(23), we

get the following criterion expression for evaluation of absence of detonation

disruption:

4.

RESULTS OF CALCULATIONS USING THE MODEL OF EXPLOSIVE PROCESS STREAM TRANSMISSION

While performing the calculations,

we assumed that emulsion ignition starts from exothermic decomposition of

ammonium nitrate. Then, the values of activation energy ![]() and pre-exponential factor z in formulas (11) may be defined equal to [12]:

and pre-exponential factor z in formulas (11) may be defined equal to [12]: ![]() = 169.5 kJ/mol, z = 6.8 * 1013 s-1. The value of heat

capacity of the matrix emulsion was determined in accordance with [18].

= 169.5 kJ/mol, z = 6.8 * 1013 s-1. The value of heat

capacity of the matrix emulsion was determined in accordance with [18].

Polytropic curve factor –

1.907, adiabatic curve factor – 1.289;

Heat of explosion – 596.5

kcal/kg; specific volume of gases – 1093 l/kg;

Density of explosion gases in

the head end of the stream – 0.0457 g/cm3;

Temperature of explosive gases

in the head end of the stream – 628 ºK;

Pressure in explosive gases in

the head end of the stream – 20.9 MPa;

Pressure in the area of

violent chemical reaction – 1.69 GPa

Velocity of the gas

stream flowing out from the area of high pressure – 3837 m/s;

Velocity of the air

blast wave propagating in front of the stream – 4221 m/s.

Duration time of

chemical reaction – 56.2 μs; Induction time of emulsion ignition – 51.7

μs;

Criterion of

absence of reaction disruption – 0.982 (~1).

Hence, the idea of the low-density EE initiation by the streams of

explosive gases flowing out from the area of high pressure allow us to obtain

numerical values of VOD that are close to the experimental values.

5. INDUSTRIAL EXPERIMENTAL

TESTING

Industrial-experimental testing of possibility to perform perimeter

blasting using a low-density emulsion explosive sensitized with polystyrene

foam beads was carried out by OAO “Uralasbest” (OJSC) through

industrial-experimental blasting of 141/15-center block [1].

The EE was prepared by

mixing-charging machine TSZM-11 (ÒÑÇÌ-11) in the process of hole charging.

During the experiment, 98 dry

holes of 115 mm diameter were blasted.

Length of holes – 16.5 m;

length of charge – 12.5 m. Charging density – 0.485 g/cm3.

Instantaneous initiation.

Presplitting quality when

blasting with low-density EEs is comparable with blasting quality in the

process of presplitting with garland charges.

Despite its low density (less than 0.5 g/cm3), the EE has preserved the

ability for decomposition.

6.

CONCLUSIONS

In low-density EEs

sensitized with polystyrene foam (or other similar) beads, it is possible to

provide stable propagation of detonation-like wave of emulsion drops combustion

in explosive gas streams flowing out of the high-pressure area of the reaction

zone.

At that, gradual

pressure increase is observed in explosive decomposition products, which is

advantageous for performance of gentle blasting.

A method was

developed for determining parameters of decomposition of low-density EEs.

Analytical criteria

were obtained for evaluation of propagation stability of this process.

The research

results allow obtaining useful information for creation of new types of

low-density EEs, and validation of gentle blasting technology with the use of

such EEs.

ACKNOWLEDGEMENT

Authors express

their gratitude for useful discussions of the issues under study to Doctor of

Engineering Sciences, Associate Member of the Hungarian Academy of Sciences,

V.V. Andreev.

REFERENECES

1. I.Y. Maslov. Increasing the efficiency of

blasting preparation of enclosing rocks at Kuzbass open casts with the use of

emulsion explosives sensitized with polystyrene foam beads / Ph.D. thesis in

Engineering Science, major 25.00.20, M., 2013. – p.132.

2. M.S. Shalaev, G.P. Paramonov. On the

question of increasing the efficiency of screening slot by selecting a rational

design of perimeter charge. Blasting work No.103/60. M.: Inter-Departmental

Commission on Blasting Works at Mining Science Academy, 2010. pp.190-199.

3. S.A. Gorinov, I.Y. Maslov. Evaluation of detonation parameters of

emulsion explosives sensitized with plastic polymicrospheres: Individual

articles of Mining Research and Information Bulletin (scientific and technical

journal). – 2011 – No.7. – pp.53-63. - M.: Publisher “Gornaya Kniga” – 2011

4. V.V. Andreev, A.P. Ershov, L.A. Lukyanchikov. Two-phase low-velocity

detonation of porous explosive / Physics of combustion and explosion, 1979,

vol.15, No.1, pp.89-93.

5. I.Y. Maslov. Evaluation of characteristic density of emulsion

explosives sensitized with polystyrene foam beads / Mining Research and

Information Bulletin (scientific and technical journal). – 2014. – No.6.-

pp.3-10. .- M.: Publisher “Gornaya Kniga” – 2014ã.

6. S.A. Gorinov. Approximating method of detonation parameters

calculation for low-density ammonium nitrate explosives // Mining Research and

Information Bulletin (scientific and technical journal), 2010, No.10,

pp.244-256.

7. Theoretical evaluation of influence of oxidizing agent’s chemical

nature on detonation characteristics of emulsion explosives / S.A. Gorinov,

V.P. Kuprin, I.L. Kovalenko, E.P. Sobina – In the book: Developing resource

saving technologies in blasting works. - Ekaterinburg, pub. Ural Branch of the

Russian Academy of Sciences, 2009, pp.191-201.

8. S.A. Gorinov. Theoretical evaluation of detonation parameters of

granemites. // Mining Research and Information Bulletin (scientific and

technical journal), 2010, No.8, pp.121-130.

9. B.N. Kutuzov, S.A. Gorinov. Physical and technical basics of creation

of emulsion-type and granular explosives, and the means for their initiation.

// Mining Research and Information Bulletin (scientific and technical journal),

2011, No.7. Preprint. pp.34-52.

10. F.A. Baum, K.P. Stanyukovich, B.I. Shekhter. Physics of explosion.-

M.: pub. Fizmatgiz, 1959. p.800.

11. V.N. Vilyunov. Theory of ignition of

condensed substances.- Novosibirsk, Science, 1984.- p.189.

12. Theory of combustion and explosion. P.P. Kukin, V.V. Yushin, S.G.

Yemelyanov, et. al. – M., pub. Urait, 2014.- p.435.

13. A.N. Dremin. Pulsating detonation front / Physics of combustion and

explosion, 1983, No.4, vol.19, pp.159-169.

14. V.G. Levich. Course of theoretical physics. Vol.1.- M.: Science,

Chief Editorial Board of Physics and Mathematics Literature, 1969.- p.912.

15. L.D. Landau, K.P. Stanyukovich. On studying detonation of condensed

explosives. / Reports of the USSR Academy of Sciences, 1945, ò.46, ¹9,

ñ.399-402.

16. V.N. Belopomestnykh. Acoustic Grüneisen

parameter of solid bodies // Letters to Journal of Technical

Physics.- 2004.- Vol.30, issue no.3, pp.14-19.

17. E.P. Tesleeva. Research of polymorphic transformations in

ion-molecular dielectric materials through methods of physical acoustic and

thermal physics // Author’s abstract of the Ph.D. thesis in Physics and

Mathematics, Barnaul, 2006.- p.22.

18. S.A. Gorinov, I.Y. Maslov. Thermal-physical properties of

non-sensitized emulsion matrix – a component of emulsion explosives // Mining

Research and Information Bulletin (scientific and technical journal).

Individual articles.- 2011.- No.12, pp.17-20. - Ì.: pub. “Gornaya Kniga”.