Технические

науки/6.

Электротехника

и

радиоэлектроника

Коляска

А.Г.

Національний

технічний

університет

України

„Київський

політехнічний

інститут“

Influence

of operating factors on the reliability

of induction motors

Induction motors - the most

common electrical machines. Increasing their reliability and durability

provides a large technical and economic effect in various industries.

Despite

the continuous improvement of production technology and safety regulations in

the steel and coking plants in the area of the working environment there are

high temperature and dustiness. To combat these harmful factors of environment

use ventilation to the inflow into the room air and water or aerosol droplets

showering, increases the humidity in the production rooms.

The study of information on

the operation of induction motors in various industries showed that 85-95% of

failures occur due to damage to the stator windings; 2-5% failure rate -

because of damage to the bearings. Cause of failure is low quality engine production

(30-35%), the shortcomings of operation (35-50%) and mismatch Motor Design

operating conditions (15-35%) [2].

During

operation, the performance reliability of electrical machinery operates a set

of operational factors, which can be divided into three groups:

electro-mechanical, climatic factors of the working environment and casual. By

electromechanical load factors include the induction motor (IM), switching

frequency, vibration, electrical voltage. By climatic environment factors

include temperature, humidity, dust air. Under the random factors understand

mistakes or incompetence of staff, leading to breakdown of electrical machines.

Thus,

the failure rate of an induction motor in the conditions of metallurgical plant consists of three

components

![]()

where![]() ,– failure rate of an induction motor, caused by electromechanical,

climatic and random factors respectively.

,– failure rate of an induction motor, caused by electromechanical,

climatic and random factors respectively.

During the year the mean values of

electromechanical factors have seasonal variations. However, the intensity of

the plant will affect the intensity of induction motor work. The failure rate

or the load can be attributed to both the constant and the variables

influencing factors.

Climatic factors: average temperature, relative

humidity, air dustiness of the working environment depend on the climate and

have a strong seasonal dependence. Consequently, the failure rate of the

induction motor due to climatic factors of production will be variable.

Random factors can not be accurately predicted.

They are more dependent on the professionalism and competence of personnel.

fight with them in every enterprise has individual character. In the

production environment metallurgical plant on asynchronous motors will affect

both electromechanical and climatic factors. An analysis of the operating

experience of induction motors found that the failure rate at nominal

electromechanical and constant climatic factors of production is 1,3![]() 10-5 or

below. Analysis of the failure rate of induction motors demonstrates that they

are mainly caused by climatic factors, while the effects of electromechanical

factors insignificant.

10-5 or

below. Analysis of the failure rate of induction motors demonstrates that they

are mainly caused by climatic factors, while the effects of electromechanical

factors insignificant.

In turn, in the conditions of metallurgical plant impact

on induction motors with climatic factors depends on the mode of operation.

Operating time of electric motors can be considered for the following periods:

heat, steady state, cooling and simple.

The motor can be represented as a homogeneous body

heat sources (as well as its losses), evenly distributed within its volume. If

we assume that the heat losses are constant over time, the process of heating

the surface of the motor is described by the equation of heat balance [2]

![]()

where ![]() – the sum of losses in the amount of motor, W;

С – heat capacity of the machine;

– the sum of losses in the amount of motor, W;

С – heat capacity of the machine; ![]() – excess surface temperature of the

motor on the ambient temperature. The heat

capacity of the machine may in turn be determined by expression

– excess surface temperature of the

motor on the ambient temperature. The heat

capacity of the machine may in turn be determined by expression

![]() где

где ![]() – specific heat of the material of the motor, J

/ kg × º C; m machine

weight, kg.

– specific heat of the material of the motor, J

/ kg × º C; m machine

weight, kg.

During operation, the temperature

of the motor winding insulation is much higher than the ambient temperature, so

the surface insulation evaporates humidity, i.e. insulation dries.

During operation, the temperature

of the motor winding insulation is much higher than the ambient temperature, so

the surface insulation evaporates humidity, i.e. insulation dries.

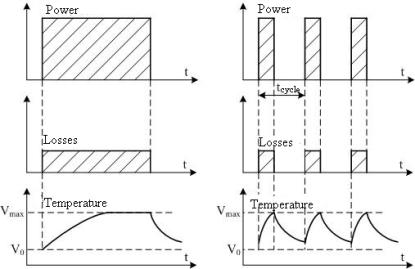

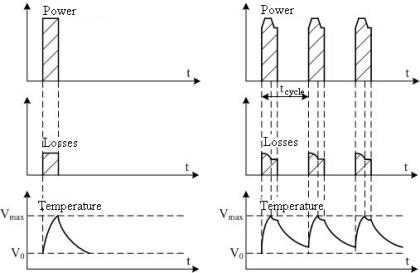

a c

b d

Figure 1– Variation of load, losses and temperature

of the induction motor in different operating modes: а – S1; b – S2; c –

S3; d – S4

Analysis

of the influence of operational factors on induction motors leads to the

conclusion that the high dependence of the motor failure on climate conditions

observed at 20-22 or more stops per day (modes S2-S8). At motors with

continuous operating mode (S1) depending on climatic factors is almost

negligible.

It can be

concluded that the development of mathematical models electric motors

reliability indices along with electromechanical factors need to consider the

impact of climatic factors and mode of operation of the induction motor.

References:

1. Radin V.I. Induction machines: Textbook for

electromech.. spec. univ. / Radin V.I., Bruskin D.E., Zorohovich A.E.; Edited

by I.P. Kopilov– M.: High sch.,

1988. – 328 p.

2. Handbook

of electrical machines / Under the total. Ed. I.P. Kopilov, B.K. Klokov. V. 1.

M.: Energoatomizdat, 1988. 456 p.