On

the question of the creation of promising hoisting cranes

Sazambaeva

B.T., Sarguzhin M.H., Beisenova A.S., Zhanabay A.G.

Kazakh

National Technical University after named K.I.Satpayeva

Kazakhstan

Turdaliev

A.T., Sazambaeva B.T., Sargozhin M.H., Zhanabay A.G.

In

work the is intense-deformed condition of a flying beam of the bridge crane is

shown. The technique durability calculation of the

bridge of the crane includes: solid-state modelling for definition of the is

intense-deformed condition of the bridge of the crane by a method of final

elements.

Crane-structural

industry of Republic of Kazakhstan, in compare with the Europe, was and remains

focused to get the fabricated parts and mainly to satisfy with the

domestic needs of intensively working

industry. Therefore, the main direction in elaboration and manufacturing of

bridge cranes is the maximum provision with the secure exploitation reliability

and durability. It causes the calculation of cranes steel structures.

In the sphere of

hoisting machinery of RK is the issue of decreasing of metal content

constructions of hoisting cranes. The weight saving of created cranes can be

conducted in the following ways:

· by optimization of constructive decisions.

· by using of high quality steel structures

· by the reasonable calculated criteria of bearing capacity of cranes

structures and its differentiation.

Further improving of

hoisting cranes constructions can be achieved with the method calculation of

improving by bearing capacity, durability, security with the dynamic effects of

loading.

The creation of

perspective constructions of hoisting cranes requires analysis and exchanging

of experience of investigation, constructing, manufacturing and exploitation of

bridge cranes with the aim of establishing of national and international trends

in this machinery sphere, deeply studying of information as per its

constructions and parameters, that will help the constructors and designers to

focus on this created projecting system of bridge cranes in the world.

Due to it, in many

cases, in problems solving of dynamic of elastic system with the distributed

parameters is widely using the methods of leading them to the concentrated

mass, which allows to use their simplified dynamic models during calculation

and steel structures investigation, and that’s why the most important

characteristic of dynamic models of steel structures are: mass, rigidity,

frequency and natural oscillation period.

The preliminary, right

choice of constructive schemes and cross sections of steel structures elements

and calculation by using of modern

programmes during the exploitation process of hoist cranes provide the

stability, rigidity and durability.

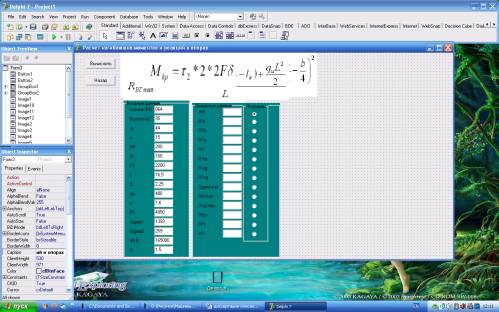

In this work it’s showing the calculations of beam

with the bending moments and reactions in supports. For programme creation it

was used the object-oriented model of software components – Delphi language and

connection with the object model AutoCad, solid Work. Delphi allows fully to

integrate the designing with the COM objects. Architecture support CORBA

(Common Object Request Broker Architecture) opens in front of the applications

created in Delphi for intel platforms (Windows + Intel), the world of other

operating systems (UNIX, OS/2, WMS). The developed software takes into

consideration the bending moments and reactions, also automatically gives the

corresponding formula by pressing “calculation” in the main page, picture 1.

Picture 1 – Definition of twisting and bending moment

of main girder of bridge crane

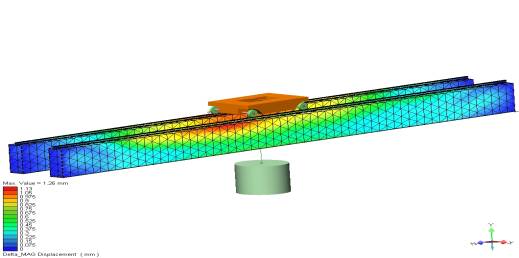

For consideration of

stress-strain status in complex loading of span beams (tension – compression,

bending and torsion) except the usual geometric characteristic, its crossings and given powers it’s

necessary to determine some additional geometric characteristics of crossings

and the power factors were used Solid Work.

Having the conditions of

fastening an loading of span beams of box section of given longitude and lateral powers, that applied to the current case 1, warping

section will be different, that will give the appearance of additional, normal

and concerned stress of crossings, that could be achieved the volumes

comparable with the main bending stress. By load factor changing and trolley moving

we receive the loading of span beam, when the trolley is in the medium part, in

the picture 2 shows the stress-strain status of span construction (box section)

of bridge crane with 16T loading and span

length 16,5m, uplifting speed 0,14 m/c, trolley moving speed 0.71 m/c.

type of crane rail RP-50. From the

pictures we see that the medium part of the bridge under the trolley is the

more loaded. The constructed model of bridge crane is loaded with the different

capacity from 3.2t to 16t. After, the

model is created and it is entered all necessary corrections, it was done the

following actions: the first – fastening of the model, model dividing in the

final elements, the step of dividing is 200mm and after going to APM structure

3D, where with it calculates; the second – gives the appropriate loading: the

weight of trolley with uplifting mechanism, moving, (in the scheme shows the

trolley without mechanisms, but the weight of these mechanisms is taken into

consideration); estimates its stress-strain status. Loading map allows to

analyze the distribution of different internal reacted power factors (forces

and moments) during model construction elements using by the dialogue settings,

can be checking the results of components and normal stressing in the plane of

axes X and Y of local system of construction coordinates. From the picture 2

it’s seen, that the medium part of bridge under the trolley is more loaded.

Picture 2 – Map of

equivalent stress model of the transit beam bridge crane when the truck in the

middle of the bridge

The conclusions:

· The right choice of constructive schemes and sections of steel

structures elements, calculation by using of modern programmes during hosting

machines exploitations provides them with the stability, rigidity and

durability.

· The strain stress status in the complex loading of span beam of hoisting

machines (tension-compression, bending and torsion) can be determined by the

method of final elements with the using of modern programmes.

· The map of equivalent stressing of model construction allows determining

the more loaded parts of constructions.

REFERENCES:

1. Vershinsky A.V. «Manufacturability and bearing capacity crane metallic»

- M.: Mawinostroenie, 1984.167 paper.

2. Alexandrov M.P., Gohberg M.M. « Reference cranes, Volume 1, 2» - L: Mawinostroenie,

1988.