Engineering science/mechanical Industry

ÓÄÊ 666.97.052

Candidate of technical sciences Nurmukhanova A.Z., Candidate of physical and mathematical sciences Mukhtarova M.N., Nurseytova A.K.,

Konakbaev B.O.,

Ermaganbetova S. D.

Kazakh National University named after Al-Farabi, City

of Almaty

Republic of Kazakhstan

Analysis of the causes of concrete made installations’

failures

Before the

country’s building complex there are major problem issues which include the

further industrialization of construction area, serial converting it into a

single process of building the objects from prefabricated elements,

acceleration, creation of advanced technology systems, machinery that provide

comprehensive concrete mechanization works, replacing of time-consuming manual

work by mechanized.

Concrete and

construction mortar is one of the basic building materials. Widespread use in

construction is explained by benefits such as the ability to use in any environment

where there are astringent and local building materials or waste products.

Moreover, concrete and mortar have good performance properties such as high

compressive strength, and in the case of reinforcement - bending and

stretching, high durability, cold resistance, heat resistance.

Normal setting

and hardening of astringent materials occurs at 20 ° C. In the case of

temperature lowering the setting and hardening speed slows down, and at subzero

temperature these processes are slow. In order to create normal conditions for

the concrete hardening in the cold season we need to preliminary heat

aggregates and water or use chemical additives for concrete’s hardening.

For the

preparation of concrete mixes or mortars hardening at subzero temperatures,

liquid antifreeze additives are used (sodium nitrite, sodium nitrite in

combination with calcium chloride, potassium, calcium nitrite in combination

with urea, a compound with urea, calcium nitrite, calcium chloride, calcium

nitrite). The content of additives should not exceed 10 ... 15% of water dose

or 5 ... 7% of the cement dose. In order to increase mixture’s fluidity

simultaneously with antifreeze additives plasticizing are introduced. For

storage convenience is recommended to prepare chemical saturated mortars’

additives. The amount of additives is set in the laboratory and the driver must

strictly withstand them.

The temperature

of the mixture at the outlet of the mixer in winter conditions should not be

below than 5 ° C. The temperature of

the mixture while existing of the mixer, as well as water temperature and

aggregates are being controlled not less than in 2 hours.

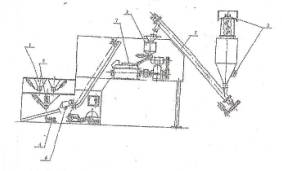

Mixing plant

(Figure 1) works as follows.

Inert materials

are loaded by front loader into the storage hopper 1. To improve the fluidity

of inert materials the installation is equipped with vibrators 2, further

through the shutters inert materials are preceded into the hopper.

Simultaneously

with a supply of inert materials cement’s 3 batcher, water and chemical are

filled by the specified quantity. Cement and batcher 4 are supplied from the

cement warehouse. Supply control is carried out by control panel. Water supply

is provided by the tank’s pump. Pump control is made from the driver’s cab.

For the operation

of gate dosing and unloading concrete mixers, mixing plant is equipped with

compressor installation 5 with receivers, pneumatic cylinders control cabinets

mounted in the upper and lower blocks. Limit switch unit mounted door lock at

the lower block’s door while opening the door of lower block is de-energizes thecontrol circuit.

1-Batcher

of inert materials, 2-vibrator, 3-batcher of concrete, 4-pump K 20/30, 5-screw,

6-skip rink, 7-mixer

Figure

1

When approaching

the unloading position and opening the shutter, roller shutter runs into the

wall of the bucket mixer neck. Inert materials for receiving the neck are

poured into the mixer 7. After unloading of inert materials is completed, water

dispenser’s valves, cement and if necessary chemical additives are opened, and

at that moment the concrete mixing is made. Bucket returns to the discharge of

the metering device, which is signaled by a limit switch installed in the

loading bucket. Where in the dispensers

of water, cement and chemicals’

additives are closured, and the cycle of

their loading repeats in parallel with the blending in mixer

plant.

Smooth operation

of concrete prepared plants requires high reliability of its constituent

machines, which should regulate the correctness of their operation and quick

recovery in case of failures.

Literature:

1.

Nurmukhanova A.Z., Povetkin V.V., Sosnin V.À. Certificate of authorship ¹ 66405 Centrifugal mixerfrom 15.12.2010,

bul. ¹ 12 s. Astana.

2.

Nurmukhanova A.Z. Evaluation of the

technical condition of the equipment stationary concrete preparatory works.

//Proceedings of the X Anniversary International Scientific Conference

"Science and Education - a leading factor in the strategy" Kazakhstan

- 2030 ". Issue 2 -Karagandy, 2007. - P.454 – 456.

3.

Nurmukhanova A.Z. Analysis of the

causes of failures betonoprigotovitelnyh installations. //Proceedings of the X

Anniversary International Scientific Conference "Science and Education - a

leading factor in the strategy" Kazakhstan - 2030 ". Issue 2 -

Karagandy, 2007. - P.457 – 459.

4.

Erehinsky V.V. Efficiency and

quality of construction. Gorkiy: Volga - Vyatka book. publishing house, 1981.

-223 p.

5.

Kessel L.A. Cost-effectiveness of

new technologies and methods for its determination. – Ì.: GosINTI, 1976 y.