Gladky F. F., DPhil, professor, Chumak O.P., candidate of technics,

DPhil, professor, Markov K. V., junior research fellow, Gasuk K. V., senior staff

scientist,. Usichenko O. V, master

National Technical University “

Kharkov polytechnic institute”, (Ukraine)

To question about enzymatical technology of

modification and refining of fats

Transformation

of accompanying to fats substances (phospholipids, fatty acids) using enzymatic

preparations was studied and the results of such transformations were analysed.

During the research there were determined new ways for developing of refining

methods, main regularities in fats (acylglycerines) enzymatic transformation

like ethanolysis and hydrolysis. Modifying of acylglycerines was carried out by

their interesterification with the appropriative esters using specific

lipolythic enzymatic preparations, that allowed producing of special

confectionary fats of high quality.

Рассмотрены результаты исследований преобразования

сопутствующих жирам веществ (фосфолипидов, жирных кислот) с помощью ферментных

препаратов. Определены новые пути развития методов очистки жиров, основные

закономерности преобразования жиров (ацилглицеринов) под влиянием ферментов, в

частности етанолиза и гидролиза. Осуществлено модифицирование ацилглицеринов

путем переэтерификации с этиловыми эфирами

соответствующих жирных кислот при участии специфических липолитических

ферментных препаратов, что дало возможность получения специальных кондитерских

жиров высокого качества.

Presently in Ukraine as wells in

other countries, fats are refined from accompanying substances with traditional

methods which are based on usage of alkalis, acids, etc.

A part of accompanying substances

are extracted from fats in vacuum/ This process is highly energy consuming and

produces waste substances. Thus, studing and research of substances

accompanying to fats is an important problem.

The substances which accompany to

acilglycerines in fats are: fatty acids, waxes, phospholipids, coloration,

taste- and odour related substances: sterols, non-specific accompanying

substances.

The object to research is a group of

activated and water soluble enzymes, both specific and non-specific, and substances

accompanying to fats like phospholipids and fatty acids.

All the exiting methods and

technologies of enzymatic hydrotation are based on the reaction of oil

phospholipid hydrolysis usingphospholipases hydrolase subclass enzymes

(according to the international

classification К. Ф

3.1).

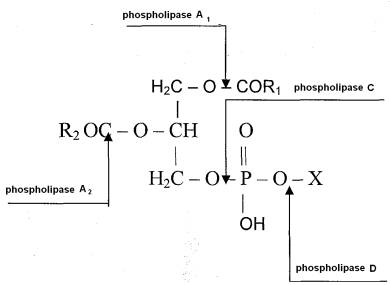

They catalyze the the process of

transforming of phosphorous-containing compounds (contained in fats, so-called

phosholypids), i. e. stimulate the reactionof hydrolysis of ester-link in a

phosholypid molecul. Among them are, phospholipases A1, A2,

C and D which differ from each other in their ways of influencing the

substrate.

The fundamental mechanism of enzymes

influencing phospholypids looks like:

where R1, R2 – saturated

or unsaturated oil carbonic remainder of fatty acids;

X – hydrogen, nitrogen base or polyol

remainder.

Phospholipases

A1 (К.Ф. 3.1.1.32, phosphatid-1-acilgidrolases), catalyze

hydrolysis of phospholypid molecule’s ester-link in α-position. They are

contained in pancreatic gland juice of animals and people [1].

Phospholipases A2 (К.Ф. 3.1.1.4,

phosphatid-2-acilgidrolases), which catalyze hydrolysis of phospholypid

molecule’s ester-link in β-position are divided into 3 classes: venom

enzymes (insects, snakes, scorpions, bees, etc); grass enzymes; intracellular

which are contained in plants and microorganisms tissues [2]. They differ

substantially in structure, substrat specificity, biological effects, and

physicochemical properties [3]. An active and the most studied enzyme of this

type is contained in venoms [1-4].

Phospholipases A2 (К.Ф. 3.1.1.4.3, catalyze

hydrolysis of molecule’s ester-link between diacylglycerin and substitute

phosphoric acid; well-known phosphatidilholine-holinephosphohydrolasa and

phosphatidilinizitol-inozitolhosphohydrolasa) are contained in bacterial

toxins. It was found in tissues of animals, including brain tissues in little

quantities in bound state [1,5,6].

Phospholipases A2 (К.Ф. 3.1.4.4, catalyze

hydrolysis of molecule’s ester-link between

phosphatic group and alcohol in a phospholipid molecule) is contained in

plants’ tissues (cabbage, roots of radish, cotton plant seed, etc), as well as

in tissues of some animals like rats.

After having analyzed an assortment

of phoshpolipase and having studied a proposition of enzymatic specimens on

the market , it was decided to choose the industrial phospholipase A specimens (produced by Denich “Novozymes” company) and available in Ukraine titled

phospholipase.

The target was to: 1) define the

conditions for using hydrolyze-type enzymes for producing phosphoypidic lysoforms and etherification of fatty acids, contained in fat; 2)

identifying main regularities of fat

accompanying substances bioconversion.

The main scientific results of the

performed research consist in identify regulation of substances accompanying to

fats – phospholipids and fatty acids using lipolitic enzymes. Also there were

calculated content and composition of phospholypids and fatty acids in new

breeds of sunflowers, provided by Ukrainian Academy for agricultural sciences.

It was investigated kinetics of

phospholipids hydrolysis and the maximal speed of this reaction was calculated

as well as effective temperature and Michaelis constant.

It was proved scientifically that

mainly lysophosphoydilamins and lysophosphoydilcholin content is increased

after enzymatic hydrotation.

Also it was proved a possibility of fatty acids(which

are contained in sunflower oil) by ithanol. This fact makes possible creation

of a new foodstuff, i. e. oils enriched by easy digested components (ethyl

esters of fatty acids).

Authenticity of scientific results

was confirmed by data obtained in industrial conditions at Pology oil-extracting

plant.

It is known a method of refining

oils from fatty acids by distillation under reduced pressure and high

temperatures. The imperfections of the method are appearing of dark-colored

substances having unpleasant smell, and highly energy-consuming.

There is a method of oils and fats

refining when they are treated with alkaline agents, for example, by sodium hydroxide

water solution under the temperature of 40 - 90°C [7].

Imperfection of the method is that

fatty acids (which are refined, when being

processed by alkaline agent) are transformed into fatty acids salt –

soaps. During this process, water solutions of soaps are formed which emulsify

oil or fat, creating fat – containing yield of production process – a

soapstock. A mass of soapstock increases when oil’s acidic number is increased.

In addition, sodium hydroxide is a dangerous substance that requires specific

measures for safe using of the method.

The goal was to simplify the

technology of oils and fats rectification using enzymes. And the goal was achieved

by using glycerin (instead of alkalines) which was used for treating oils and

fats in presence of specific lipolytic immobilized (or non-immobilized) enzyme, kipping the mass

proportion of oil or fats: glycerin: enzyme equal to 100: 0,5÷5 :

0,1÷10, the temperature is 30 – 80°C, pressure is 20 – 50 mm Hg vacuum

during 0,5 – 15 hours.

After enzymatic refining, acidic

number changes for oils is shown in table 1.

Table 1 – Changes of acidic number for oil

using enzymes

|

№ |

Enzyme |

Initial acidic number, mg KOH/g |

Final acidic number, mg KOH/g |

Time of reaction, hours |

|

1 |

Lypozyme RMIM |

4,5 |

0,3 |

7 |

|

2 |

Novozeme 435 |

5,2 |

0,2 |

3,5 |

|

3 |

Novozeme 435 |

5,8 |

0,25 |

7 |

|

4 |

Lypozyme TLIM |

3,0 |

0,3 |

6 |

Advantages of such a refining method

are; single-stage refining; fatty acids are not extracted from oils or fats buy

are transformed into acylglycerins; lack of wastes; degreased losses of product

oil or fat; glycerin as an agent, is

much more ecological and safe stuff comparing to o-phosphoric acid and caustic

soda.

A patent №30031 “Method of oils and

fats refining” was issued on 11 Feb 2008.

A particle value of performed research is

outlining of new ways of development methods refining fats from accompanying

substances using enzymes.

It has to be said, that now in

Ukrain, as in other CIS countries producing of foot supplement – ethyl esters

of fatty acids, mono- and diacylglicerins, which are classified as substances

for improving food stuff quality, is performed

using chemical agents (alkaline, acids etc).

The technology of such products is

quite complicated and energy consuming. More than that, refining of final

products leads to appearing of essential amount of waste products. For example,

mono- and diacylglicerins synthesis requires using of special equipment (target

monoacylglicerins fraction is extracted by molecular distillation) [8,9].

That is why researching of fats

transformations by using enzymes, and finding conditions for producing target

products using lea energy consuming methods and high yield are actual and necessary.

The researches’ goal was to

determine fundamental laws of fats (acylglicerins) transformation under

influence of enzymes, particularly

ethanolysis and hydrolysis.

The final goal of design was

implemented by the following steps:

· appraisal of properties of enzymatic

preparation produced industrially or having experimental-industrial status;

· determining of external factors

influencing the parameters of the appropriative reactions;

· determining of optimal conditions

for obtaining esters of fatty acids and incomplete acylglycerines.

Stated below are the results of this

scientific research.

It was proved a possibility of using

enzymatic preparation on the carrier Lipozym TLIM, Lipozym RMIM and Novozym 435 to transformation of acylglycerines

(fats), particularly alcoholysis, aided by mono- and polyatanomic alcohols.

It was revealed that during

ethanolysis reaction, the highest level of triacylglicerins transformation

using Lipozym TLIM is 82% (weight), using Lipozym RMIM is absolute 80% (weight)

and the highest level of transformation

is 94% (weight) when using Novozym 435.

It was found that during glycerolysis reaction

the transformation level os triacylglycerins using Lipozym TLIM is 34,4%

(weight), using Lipozym RMIM – is 17,4% (weight), and the highest level of

transformation is 85,5% (weight) when using Novozym435.

The optimal conditions for

alcoholysis are determined as: period length for the most high speed reaction –

2 hours; tge temperature for Lypozym

TLIM and Lypozym RMIM is 30 – 35°C, and for Novozym – is 60 - 70°C;components

proportion is stoichiometric.

Posibility of the pbtained results

is proved by their correlation on conditions using different measuring ways.

For example, the data related to the reaction product composition, calculated using thin-film chromatography, are

proved by dividing those product on adsorbing columns, by measuring viscosity,

refraction factor, and using chemical methods.

Also important is the problem of

detection of main regularities of enzymatic interesterification implemented to

ethers of mono- and polyatomic alcohols as a method of fats modification.

Promising and timeliness of research

work is proved by the possibility of creating new fats – related technologist

based on the obtained results. Such technologies are also important for

confectionary industry.

For the moment , such fats are imported

from abroad.

Scientific actuality of research is

proved by absence of important related to interesterification of esters of

mono- and polyatomic alcohols in special literature.

Producing of high quality confectionery fats possible by

multifunctional fractionating of palm

oil and other oils. This method is labor-intensive and requires sufficient

power inputs. Using partky-hydrogenizated oils (for example, sunflower oil,

rape oil, etc) as special confectionary

fats does not allow to produce high- quality confectionary. In addition, there

is a considerable quality of trans-isomers in such fats. Such substances, in

the judgment of some specialists, shoud

be of limited quantities in foodstuff.

One of the feasible ways of

resolving the problem is acylglycerins (fats) modification using specific

lypolotic enzymes.

We carried out acylglycerins (fats)

modification by their

interesterification with ethyl ethers of the appropriate fatty acids

using specific fat-splitting enzymatic preparations. This method allows to

obtain symmetric acylglycerine, and also asymmetrical acylglicerines when using

mixtures of esters.

A patent №79728 «Method of obtaining modified fats” was registered for this technology.

The research was awarded whit a gold medal at the III International show of

inventions and new technologies “New time” in Sevastopol city.

Analysis if the research proved the advantage of enzymatic technologies:

production cost price redaction, ecological compatibility of manufacturing,

possibility of obtaining products for

various purposes, creating of waste-free technologies, and etc.

The particular value of the research

consists in rational design and deoploing into industrial production new

energy- - and recourse-saving technologies for producing: esters as food

additives, and as a fuel component for internal-combustion engines;

monoglycerines which are used as food surface-active agent fats; fats enriched with diacylglycerines as a component of foodstuff

– salad oils, margarines, spreds, confactionary fats for special purposes, etc.

Reference:

1. Арутюнян Н.С., Корнена Е.П. Фосфолипиды растительных масел. – М.: Агропромиздат, 1986. – 256с.

2. Краткая химическая энциклопедия / Под ред. Кнунянц И.Л. – М.: изд-во «Советская энциклопедия». Т.5, 1967. – 1184с.

3. Литвиненко Н.М., Кисель М.А. Эндогенные фосфолипазы А2: Структура и функция. – Минск: Навука і техніка, 1991. – 270с.

4. Муратова Р.И., Борников В.Т., Саатов Т.С. Фосфолипаза А2 и реацилирование фосфолипидов // Биохимия. – 1987. – Т.52, вып. 7. – С.1068-1071.

5. Воронин М.В., Селищева А.А., Василенко И.А., Щвец В.И. Особенности кинетики гидролиза фосфолипидов фосфолипазой С из Bacillus cereus. Гидролиз фосфатидилхолина в присутствии дезоксихолата//Биохимия. – 1990. – Т.55, вып.1. – С.75-77.

6. Евстратова Н.Г., Кленова Ю.Б., Серебренников Г.А. Получение биоспецифических сорбентов для выделения фосфолипазы С Clostridium perfringens методом аффинной хроматографии // Биотехнология. – 1992. - №6. – С.69.

7. Тютюнников Б.Н., Бухштаб З.І., Гладкий Ф.Ф. и др. Хімія жирів. – Харків: НТУ “ХПІ». – 2002. – 452 с.

8.

Krog N. Food

emulsifiers in Lipid Technologies and Applications end by Gunstone FD, Marcel

Dekker, New York/ 1997, pp.421-534.

9.

Hassenheuttl

G.L. Synthesis and

commercial preparation of surfactants in the food industry, in Lipid Synthesis

and Manufacture, end by Gunstone FD, Sheffield Academic Press, Sheffield, UK,

1999, pp. 371-400.