Technical

sciences/1. Metallurgy

Abdrakhmanov

Ye.S., Bykov P.О., Bogomolov А.V., Kuandykov A.B.

S. Toraighyrov Pavlodar State

University, Kazakhstan

Researching of mixing quality of briquette mass

Preparing of briquette mass

consists of 2 parts: mixing (leveling) and physic-chemical processes of all

components of briquette compositions. This processes often superimposed one on

the other, partially flow sequentially.

For assessing the qualitative

side of the mixing process, one of the important indicators is the degree of

homogenization of the mixed mass. On the limit, fully homogenized mass must

have same component and grain composition in any macro volumes. Therefore,

measure of the performance of a mixer is the standard deviation of the

composition of a sample taken after a certain mixing time, or the degree of

mixing, expressing the ratio of the actual deviation of one or another

component of the mixture to the theoretical standard deviation of an ideally

mixed mixture. The last parameter, in the limit equal to 1 (or 100%), is more

obvious for estimating the performance of the mixer.

Consequently, estimation of

mixing quality can be partially carried out from the standpoint of statistical

distribution parameters. There are dozens of formulas for quantifying the

distribution of blended components in final products. As a criterion for the

quality of mixing, the inhomogeneity coefficient (variation):

![]() , %

, %

S – average square deviation;

m ̅ – average arithmetic content of the controlled component in all

samples;

n – number of samples;

Хi- value of the

random variable X in the i-th experiment.

The quality of mass mixing is advisable to be

estimated by any control fraction of the base particles (for example, 0.8-1.2

mm or 1-1.5 mm) in single samples of Сi:

![]() , %

, %

С ̅ – average arithmetic value of the number of

particles in the samples,%.

However, as indicated at the beginning of this

section, mechanical mixing (homogenization) does not mean that the briquetting

mass is obtained as a stable polycomposition. The second stage - adhesion

(wetting, sorption), capillary impregnation, etc. provide a stable formation of

the thinnest layers on the boundary of the abrasive-substrate, which are

connected by Van der Waals, molecular and electrostatic forces. Availability of

this forces leads to the formation of a solid three-dimensional structure. Only

after the completion of these processes, the briquette mass is converted into a

cohesive, highly concentrated and structurally stabilized substance. It is the

spatial structure of molecular forces that imparts plasticity, viscosity and

stability to the substance.

For a normal (Newtonian) fluid, displacement of the

layers is caused by an arbitrarily small force. In structured systems, as a result

of the availability of a sufficiently strong continuous structural grid, some

effort must be exerted to destroy it. According to a number of articles [1-4],

flow of that system begins only from the moment when the shear stress R exceeds

some critical value Rk necessary for the destruction of the structure formed in

the given system. Such a flow is called plastic flow, and Rk is the yield

point.

In briquette mass, at operating temperatures, a

viscous flow is characteristic for normal Newtonian fluid. In the mixture mass,

as a result of a sharp increase of base concentration, an appreciable

appearance of elastic plastic properties and yield strength should be expected,

which is especially important in the formation of briquettes in roll presses.

This is what ensures the preservation of a stable form of briquettes after they

exit from the cells of the mold.

Considering the complexity of the above processes,

technological evaluation of the mixing quality of peck-coal masses has a number

of features. It is very important to evaluate the completion of the main mixing

processes: homogenization, adhesion, coating, impregnation, etc. Also

considered rheological characteristics of the masses (viscous flow and

plasticity, sedimentation in the liquid phase of the binder, press

characteristics, etc.)

We will take a look on these requirements in more

detail. For the briquette mass, the indicator of the mass bulk density or the

sometimes used residual porosity index that characterizes the degree of

capillary impregnation of the filler grains is of interest.

Methodically, this is done in the following order. The

briquette mass is placed in a detachable liner and heated in the resistance

furnace smoothly to 170 0С. When filling the mixture in the sleeve, it is

compacted manually with a wooden rammer without knocking smoothly to a density

of 1.15 - 1.20 g / cm3. After 5 minutes at this temperature, the sleeve is

pulled out and cooled in water for increasing speed of cooling. After cooling

in water, bulk density of the briquette mass is determined, which after the

cooled sample is crushed in a laboratory jaw crusher.

Then follows the grinding in a laboratory ball mill to

class - 0.16 mm.

The pycnometric density in an aqueous solution of

ethyl alcohol without boiling is determined. The porosity is determined by the

formula:

![]() 100%

100%

Р – porosity,

ρп

and ρб − micrometrically and bulk density of

briquette mass

The briquette components were first mixed in a roller

mixer in a cold powder state for 3, 6, 9 minutes. Then, 140 grams of the

stirred mixture were placed in a detachable sleeve, also heated to 170 °C, and

after standing for 5 minutes were placed on a laboratory bench and the hot

briquette was compacted by three blows of the koper. After cooling in water,

the sleeve was separated, and the sample of the briquette was pulled out of the

liner cavity and placed in a preheated oven.

After a two-minute drying at a temperature of 105 °C,

the sample was taken out of the camera, after being exposed to air for 5

minutes, weighed on an electronic balance. The experiments were performed three

times for each mixing time of the briquette components in the roller mixer. The

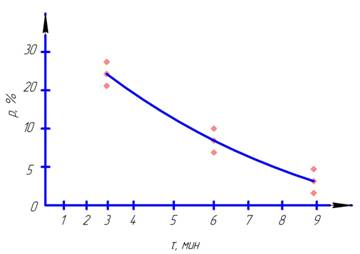

results are shown in Figure 1.

Figure 1 – Dependence of the porosity of the briquette

from time of dry blending

As can be seen from the graph, durability of dry

mixing reduces the porosity of the briquettes, that is, increases its

mechanical durability to abrasion, which is the main indicator during the

transportation of the finished briquettes. The dry mixing for 9 minutes to

reduce the porosity of the briquette noticeable influence does not render.

Therefore, laboratory tests that time will be taken as established. Next,

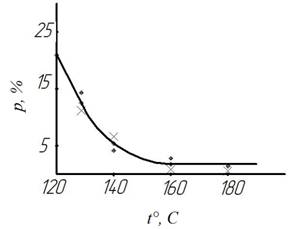

prepared mixture briquette mass split in the sleeve was heated up to 120,

130,140, 150, 160, 170 0С. The results of measurement of porosity is presented

in figure 2.

Figure 2 –

Effect of heating temperature of briquette mass on porosity

With increasing temperature in the sleeve, the volume

of unfilled pores is reduced and becomes stable at 140 ÷ 160 0C. This

consistent with the results of the study of wettability: at these temperatures

the contact angle reaches the limits of the beginning of wetting. At the same

time, unreasonably high temperature heating of the mixture can lead to

oxidation of the binder and loss of part of the cementitious properties [5].

Another indicator of the quality of mixing can serve

as the thickness of the layer of binder between the grains foundation. To

determine this figure, the briquette thin sections of the samples were studied

under the microscope. When we zooming x 200, distribution curves were

constructed according to the method [6].

Conclusions:

1 Researched and assessed

quality of the mix briquette mass through the degree of homogenization,

coefficient of heterogeneity, interaction and adhesion through rheological

characteristic briquette mass.

2. Compiled experimental

method of determining indices of volumetric mass density and residual porosity

of the briquette.

3. The optimal temperature

scale stabilization of heating the briquette mass. The optimal thickness of the

layer of binder between the grains Foundation.

References:

1 Summ B. D., Goryunov Yu.

V. Physical-chemical fundamentals of wetting and spreading. − M. :

Chemistry, 1976, 236 p.

2 Gorchakov G. I.

Composition, structure and properties of cement concretes. – M. : stroiizdat,

1976, 186 p.

3 Gul V. E., Kuznetsov V. N.

Structure and mechanical properties of polymers. – M. : Higher school, 1972,

168 p.

4 Cynarski I. S. Process

technology of refractories. – M. : Metallurgy, 1969. – 280 p.

5 Kaplanov J. V. Non-ferrous

metals, 1990, No. 7, 75 p.

6 Abdrakhmanov Ye.S, Bykov P O, Kulumbaev N K

Experimental determination of the technological parameters of a blade mixer /

Materials of the International Scientific Conference "XV Satpaev

Readings" - Pavlodar: S.Toraighyrov PSU, 2017