Yurii P. Borodii, Cand. Sc. (Eng.), Assoc. Prof.

National

Technical University of Ukraine "Igor Sikorsky Kyiv Polytechnic

Institute"

Practical Research Wear Knives for Cutting

Wire

To study the characteristics

of the process of deterioration, describe the mechanisms of wear, determining

the process parameters important to wear frakto image

research knives for cutting wire. The aim is to generalize the results frakto image and X-ray structural studies knives for

cutting wire, which are made of different materials, surface strengthened in

different ways and have worked a certain number of cycles. Cutting wire with a

diameter of 1 mm was die-machine having upper and lower moving blades fixed.

Research conducted on these

samples:

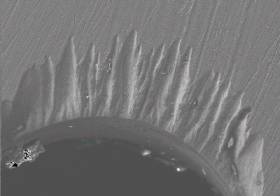

1) Sample 1 – lower than

(Fig. 1), made of steel coated ØÕ15 chromium nitride (HV 947).

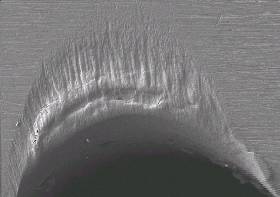

2) Sample 2 – lower than

(Fig. 2), made of steel with quenching ØÕ15 to 706...733 HV worked 12,000 strokes.

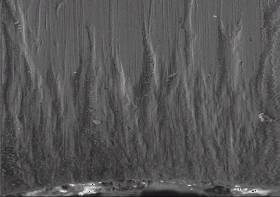

3) Sample 3 – than the top (Fig. 3), made of

steel with quenching ØÕ15 to 674...741 HV.

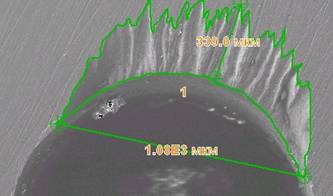

4) Sample 4 – lower than (Fig.

4), made of hardened steel ØÕ15 (HV 706...733) and electric-doping strengthened to

HV 1080-1120.

|

|

|

|

|

Fig. 1. Sample 1 after 16,000 strokes * 100 |

Fig. 2. Sample 2 after 12,000 strokes * 97 |

|

|

|

|

|

|

Fig. 3. Sample 3 after 12,000 strokes * 500 |

Fig. 4. Sample 4 after 20,000 strokes * 100 |

|

During processing frakto graphs were studied geometrical parameters zone wear

all four blades. As these parameters were determined: the absolute height and width

in millimeters zone wear and wear area zone.

The

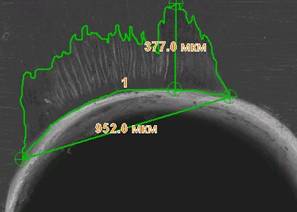

measurement of these parameters was carried out

using graphics software. For example,

in Fig. 5-6 shows the measurement

results for sample 1 (holes 1 and 2).

|

|

|

|

Fig. 5. Options wear zone (height and width) of

the sample 1 (hole 1 after 16,000 strikes) * 40 |

Fig. 6. Options wear zone (height and width) of

the sample 1 (hole 2 after 18,000 strikes) * 40 |

Since each blade carried a

different number of cycles, for comparative assessment of the stability of

knives strengthened in various ways, used the following parameters:

1) The burr growth rate (mm/thousand

strikes) was defined as the absolute value of the burr, divided by the number

of impact stamps at which this burr was formed.

2) Specific areas of wear

height (mm/thousand strikes) as defined altitude zone, referred to the number

of stamps punches.

3) Specific areas of wear

area (mm2/thousand strikes) defined as the absolute value of

the wear zone area divided by the number of stamps punches.

Results and calculations are

summarized in table 1.

Table 1

Summarized

results of processing frakto images

|

Hardness HV |

Burr

growth rate, mm/thousand strikes |

The

specific area of the zone

of wear, mm2/thousand strikes |

Specific

height zone of wear, mm/thousand strikes |

|

720 |

0,0175 |

0,0565 |

0,0775 |

|

947 |

0,0054 |

0,0123 |

0,0168 |

|

1080 |

0,0068 |

0,0188 |

0,0286 |

|

1120 |

0,0064 |

0,0084 |

0,0075 |

Conclusions:

1)

To study the characteristics of the process

of deterioration, describe the mechanisms

of wear, determining the process parameters were involved wear

frakto study graphic knives for cutting wire.

2)

Dependences of the height and

area of the

wear zone on the absolute

value of the burr are

obtained for various types of

hardening treatment of the cutting

edges of knives.

3)

The dependences of specific height

and area specific areas of wear from

the average hardness knives, cutting edges are

reinforced with different types of combination treatment.