Gudukhina А.A., Chernysheva L.P., Yasinskiy I.F., Koltsova E.A.

Ivanovo State Power

Engineering University

Ivanovo, Russia

Simulation of fluid

flow in systems with different internal configuration using parallel

technologies

I.

Introduction

Hydrodynamics

is a section of the aerohydrodynamic science, which studies the motion of

incompressible fluids and their interaction with solids. Compressibility means

the ability of a substance to change its volume under the action of

comprehensive pressure.

The objectives

of this paper:

· creation

of an application for modelling hydrodynamic systems

· exploration

of possibilities to accelerate computations using parallel programming

technologies

· comparison

of the results of the gradual and parallel implementations

II.

Mathematical model

A. Basic

hydrodynamic equations

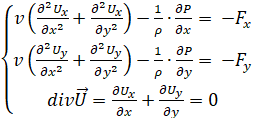

Navier-Stokes and continuity equations are used for modelling

hydrodynamic systems in this research, as the mathematical model is the most

popular among similar scientific papers. That means that fluid is ideal and its

volume will be the same during the whole process of modelling. The system of

equations (1) describes fluid flow in two-dimensional coordinates.

(1)

(1)

v – kinematic

viscosity coefficient, P – pressure, r - environment

solidity, ![]() – velocity.

– velocity.

B. The

algorithm for solving the hydrodynamics problem

1. Initialization of velocity and pressure fields.

2. Calculation of a new pressure field using old

velocity field.

3. Calculation of a new velocity field using new

pressure field according to system (1).

4. Recalculation of boundaries.

5. If one more step is required, go to point 2,

otherwise stop calculations.

C. Boundary

and initial conditions

Two types of boundary conditions are used in

this system. The first one is solid boundary. Speed axis rates are equal to

zero here. Supply and exhaust vents have one speed axis rate equal to zero, and

the other one is calculated in the way to get parabolic profile: numbers near

boundaries are seeking a null position and the maximum value is in the center

of a vent. Initially, the velocity and pressure fields in the entire modelling

area are determined to be zero. The speed is set only on supply and exhaust

vents.

III. Investigation

of systems with diffeent internal configurations

Using the system of equations (1) and described boundary and initial

conditions, systems with supply and exhaust vents were composed.

Figures 1 and

2 show stable hydrodynamic systems where arrows indicate the direction of fluid

movement in the system, and their length schematically indicate the velocity of

the fluid: the shorter the arrow, the slower the speed. The brightness of cells

indicates the degree of pressure at a certain point in the system.

Figure

1 Figure

2

By simulating the process of fluid flow in a confined

space, we can determine in advance whether a system is stable and how it could

be stabilized. Considering pressure in a system will show the places which are

the most vulnerable to the impact of flow.

IV. Parallel algorithm

CUDA technology gives an opportunity to parallelize calculations on a

grid of processors. Every processor can calculate one or several values on

every iteration. Obviously, this approach will be more beneficial for us.

Instead of calculating values in each point one by one, each thread chooses a

task according to its coordinates and calculates three values for each point.

Table 1 contains time (in seconds) of gradual and

CUDA algorithm realizations work.

Table 1 – Time of algorithms

work

|

System

Order |

100 |

300 |

500 |

700 |

900 |

1000 |

|

Gradual |

7,6 |

109,9 |

280,5 |

548,7 |

852,9 |

904,9 |

|

CUDA |

1 |

7,68 |

20,95 |

40,64 |

66,57 |

82,07 |

According to numbers presented in

table 1, CUDA algorithm is ten times faster than the gradual one.

V. Conclusion

Modelling of hydrodynamic systems is a scientific

sphere, which allows carrying out experiments and not exposing real systems to

danger. Visualization of a fluid flow and pressure distribution makes

calculations spectacular for scientists.

Mathematical model described in the paper provides

opportunity to model fluid flow in constraint environment and its parallel implementation

allows getting calculation results faster. The next step in this project will

be the creation and implementation of parallel algorithms with different

technologies.

References

1. Filatov E.I., Jasinski F.N., Matematicheskoe

modelirovanie techenij zhidkostej i gazov: ucheb. posobie Ivanovo: ISPU, 2007,

84 pp.