Экономические науки/8. Математические методы в

экономике

Dr. Sci. (Econ.) Suvorova V.V., Cand. Sci. (Econ.)

Kochevatkina E.F.,

Timarsuev M.V., Kudlovich D.V.

Balakovo institute of technical, technology and management

Вranch of Saratov State Technical University

DEVELOPMENT AND IMPLEMENTATION OF INFORMATION AND COMPUTER COMPLEX

FORTHE CONCEPT OF ACTIVE LEARNING

The

Information and Computer Complex is a shell with a set of

specialized tools for creatingof informational objects, describing of their

properties, interconnections and algorithms of information processing, as

well as the mechanism forthe interpretation of

thesedescriptions which are used for the formalization of the

calculation and graphical part of projects.

The

aim of the development of the Information and Computer Complex

is an automation ofproduction processes projection.

The

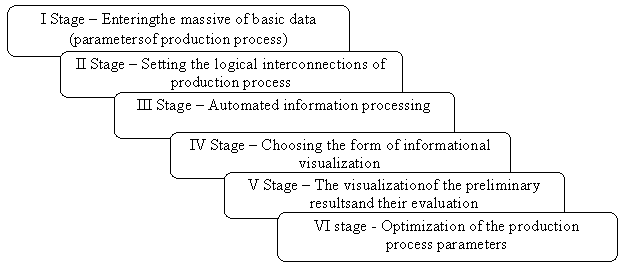

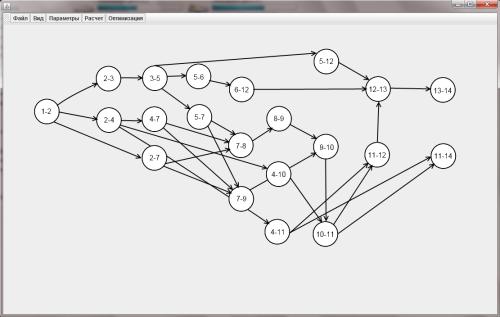

implementation of the Information and Computer Complex which is

used to solve problems of automatedprojection of productionprocesses includes

aseries of successivestages of work(in Fig. 1).

Figure 1 –Stages of automated projection in the Information and Computer Complex

Let

us examine in detail every stage of the automated projectionof production

processes implemented within the developed Information and Computer Complex.

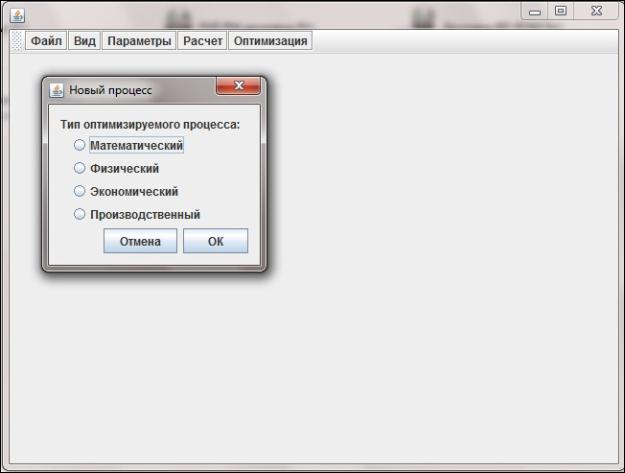

The

1st Stage - Entering the massive of basic data (parametersof

production process). At this stage a production process is being identifiedi.e.

the complex of all actions of personnel and tools which are needed for

an economical subject to make products, works or services is being determined.

Based on it the module which corresponds to this production

process is being chosen (in Fig. 2)

Figure 2 – the identification

of the production process

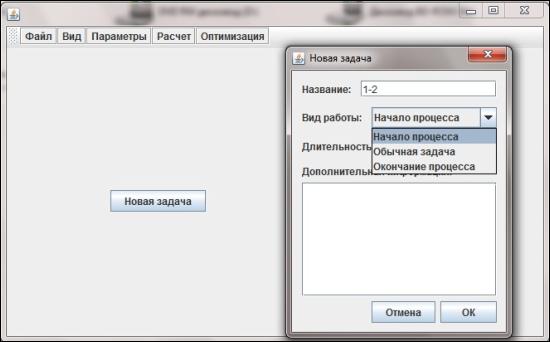

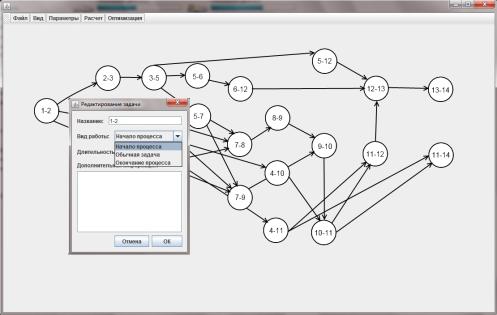

Then

the formulation of the problem begins and basic data which describes the production process, e.g. a type of work, duration, detailed

description of production process technology, is being

entered (in Fig. 3).

Figure 3 – Entering

(input)thebasicdata

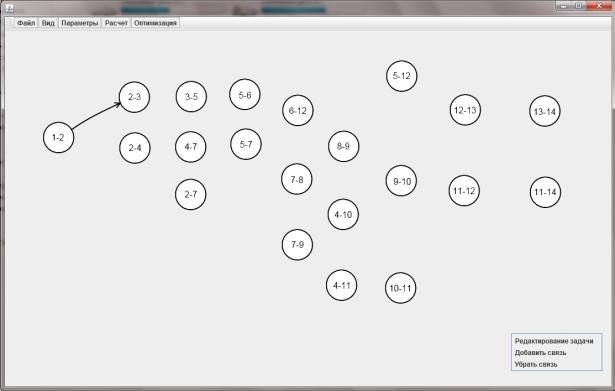

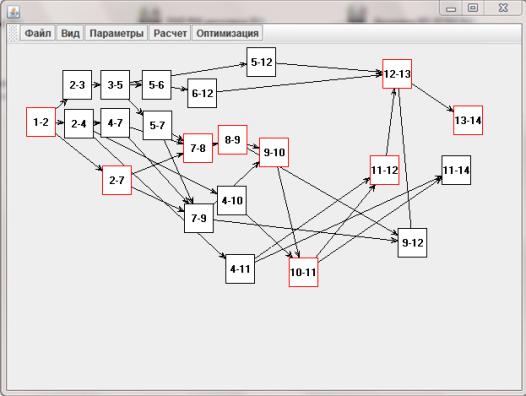

The 2nd

Stage - Setting the logical interconnections of production

process. Based on the input data the logical interconnections are set due topreviouslyidentifieda specifictype

ofmanufacturing process. In other words,the sequence of works

whichinvolve the studied production process is being formalized (in Fig.

4).

Figure 4 – Setting the logical interconnections

The

result of this stage of working in the Information and Computer

Complex is theinterpreted structure of the studied production process (in Fig.

5).

Figure

5 – The interpreted structure of the studied production process

Besides

every element of the interpreted structure contains the

information about parameters of a single work of the production process

(duration of works, encoding, description of works which are performed).

If it is necessary,these elements can be modified and/or

supplemented(Fig.6).

Figure

6 – Editing the element of the interpreted production process

structure

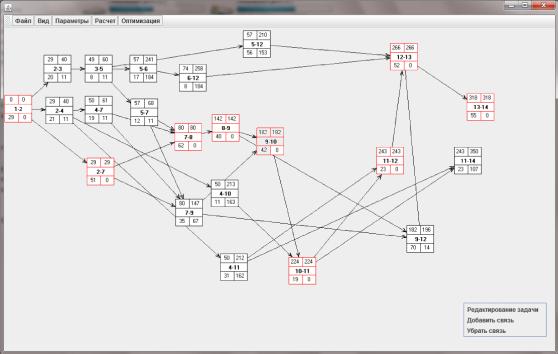

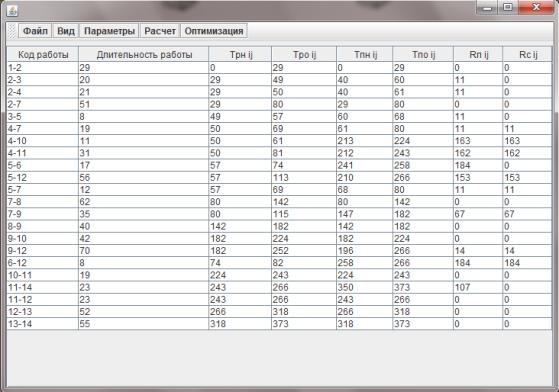

The

3rdStage - Automated information

processing. This stage of work in the Information and Computer

Complex provides automated calculation of time parameters of the studied

production process (in Fig. 7).

Figure 7 – The results

of automated information processing of the studied production

process

Based on data from fig.

7 there is a calculation of the parameters which characterize the production

process at this stage of work in the information and computer

complex.They are:

-

the critical way which describes the

duration of works with absence of time reserves;

-

the early term of

fulfillment of the event which determines the time period of performance of manufacturing operations without using the time reserves;

-

the late term of fulfillment of the

event which fixes the duration of works with full using of time reserves;

-

full time reserve which allows to

determine the amount of time which can be used to delay the performance of the

initial work stage without violation of general termsof the production process;

-

free time reserve which represents

the amount of time which can be used without any violation of early terms of

the work performance.

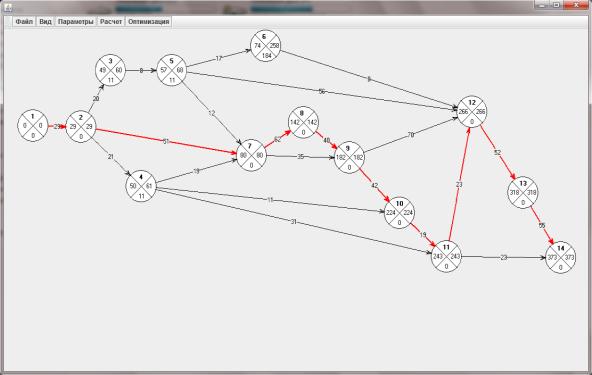

The

4th Stage - Choosing the form of informational visualization. To

analyze the data which has been resulted after processing the basic information

it is necessary to present the production process graphically that allows to

visualize the sequence of business operations which are involved into the

production process. Options of the developed Information and

Computer Complex allowto present the results of automated information

processing in the studied production process which has been calculated at the

previous stage as “a set of events”, “a sequence of works” or “a table”.

Presentation

of the results of automated data processing as a set of events is more

informative, i.e. it contains maximum amount of information and more suitable

for a user (in Fig. 8).

Figure 8 - Presentation

of the production process as a setof events

As you can see,

the presentation of the results of automated information processing as a

complex of events involves the information output about sequence of

interconnected technological operations, terms of the operation performing,

time reservesand duration of the works.

After

visualization of the automated information processing results as a sequence of

works a user gets less informative form of data presentation but at the same

time more suitable for editing and adding in case of

changing the parameters and factors affecting the production process (in Fig. 9).

Figure 9 – Presentation

of the production process as a sequence of works

The

tabular display of the automated information processing results allows to represent

analytical data as a compact integrated system which provides more efficient

way of generalization and analysis of the production process parameters (in

Fig. 10).

The

presenceof additional options allows user to adjust the interface individually.

Figure 10 - Presentation

of the production process as a table

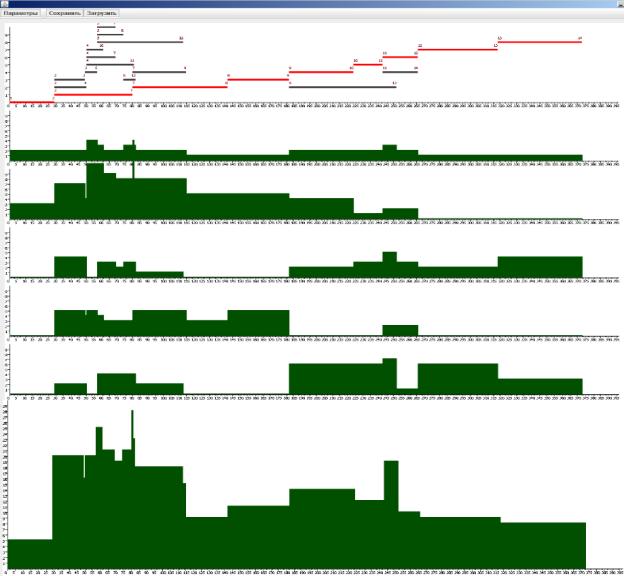

The

5th Stage - The visualizationof

the preliminary resultsand their evaluation.The visualization of the

results is being carried out as a project map which consists of ribbon diagrams and the diagrams of parametric data

forparticular parameters and the cumulative diagram which displays synergistic

effect of the complex of given parameters (in Fig 11).

The

disadvantages of existing organization of the production process are visualized

on the original production project plan.

So that “laydowns” show underutilization of existing resources and “spires”

show the overload of used resources and the necessity of involving additional

resources.

The

identified shortcomings of the production process can be corrected with the

developed byinformation and computer complex.

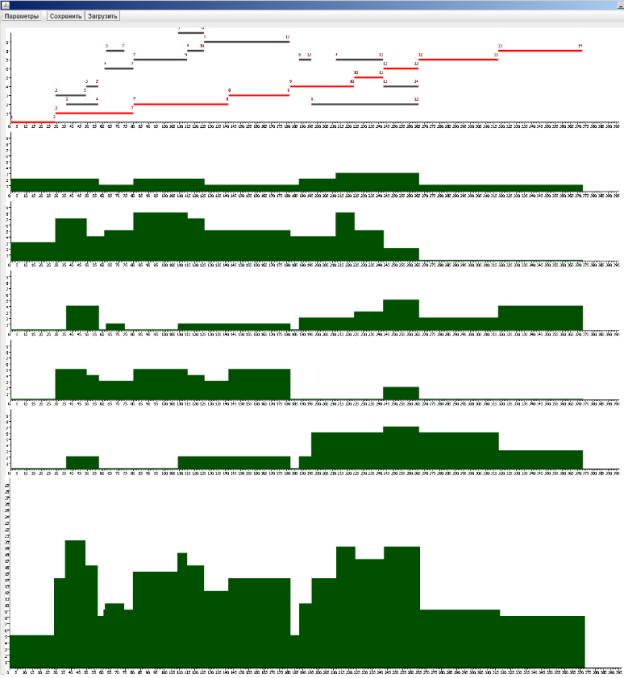

The

6th Stage - Optimization of the production process.

Basing on the results of the analysis the optimization of existing production

process is being performed. With menu command “Solution” a user adjusts the

ribbon graphs and diagrams that leads to the distribution of existing

production reserves (in Fig. 12).

Figure 11 – Basic card

of the production process

The feature of

choosing the optimal variant of production process is the lack of strict

algorithm for solving the problem. Basing on it the optimization of the

production process which is being realized in a traditional way represents non-formalized

solution of the basic problem through choosing one from many other variants

which have been obtained by the empirical method. This method suggests the

examining a generous amount of production data combinations. Herewith the

obtained result does not guarantee the optimal variant of production process.

Figure 12 – Optimized production

process card

The

using of the information and computer complex to optimize the

production process provides full automated solution process of the problem and minimizes

the possibility of making a mistake which is caused by human factor.