Technical Sciences / 8. Metal Treatment in Machine-Building

Doctor of Technical Sciences, Professor Smolentsev

V.P.,

Candidate of Technical Sciences, Professor Koptev

I.T.,

Doctor of Technical Sciences, Professor Gazizulin K.M.

Voronezh State Technical University, Russia

Kazan State Power Engineering University, Russia

Electroerosive And Dimensional Electrochemical Machining Technological

Opportunities And Future Developments

Introduction

It is impossible to create modern

technics without wide using of nonconventional methods of processing. It

includes electroerosive and dimensional electrochemical machining. The analysis

of achievements in this area for last years gives the basis to estimate

technological opportunities of nonconventional methods, to predict prospects of

their application especially at development of the high technology products of

aviation and space technics.

Electroerosive processing

The largest scientific

generalizations last years are made in the field of electroerosive geometry

generation by the none-form tool at use as the tool of a core or a wire. The

researches resulted in [1], [2], show, that for elimination of the basic lack

of electrospark process - it is offered to limited productivity to use for

strengthening impulses of intensive thermal influence of type of cumulative

effect, that on the order and more accelerates speed съема an allowance. In [3] it is reached by application of

the tool with a single-layered or multilayered covering of an electrode-tool

the metal possessing cumulative effect, for example, by zinc. The problem of

improvement of quality of a superficial layer is simultaneously solved at

intensive removal of an allowance. In figure 1 the electrode in the form of a

brass wire (1) with a zinc covering (2) is shown.

Modern means of automation of

electroerosive machine tools allow to change position of a wire so it is always

directed by a covering 2 aside zones of processing of a detail. Drop-shaped

form of an electrode (figure 1) allows to use more full a covering 2 which in

process of deterioration will reduce the size of an electrode from Н1 up to Н2, and after

calibration of the cut groove by a site (dпр - L) an electrode without a covering it is possible to lower

roughnesses on walls of a groove after intensive erosive process at

participation of a covering. The offered technical decision has allowed to

accelerate up to 10 times speed of an insertion of apertures of small diameter

or reception of narrow grooves, having provided thus roughness Ra=0,63-0,32 a

micron (on steel) and an error about 10-20 microns. Continuation of researches

on research of new kinds of electrodes and working environments can lead to

creation combined electrochemicalerosive process with technological parameters

essentially exceeding the reached level. In view of a high degree of

universality of an electrospark method it is possible to count on significant

expansion of area of use of such process, especially in the high technology

branches of mechanical engineering.

It is necessary to consider as

the second perspective direction of development of electrospark processing cold

restoration of geometry of the worn out details. Essentially new scientific

results on multilayered drawing толстослойных coverings from

pig-iron or steel with high quality of a superficial layer [3] and reception of

coverings from high-temperature alloys (for example, pig-iron) on легкоплавных aluminium materials [4] are received. The

problem is solved due to management of properties of a superficial layer of

coverings, change of thickness of each layer, by introduction in a cover zone

of chemically active environments. On the basis of the received in [3], [4]

results researches on drawing qualitative thick coverings with use of titanic

alloys that will allow to give to products from not scarce легкообрабатываемых materials the unique

operational properties provided by coverings are planned.

Fig. 1. The Electrode-Wire (1)

With A Zinc Covering (2)

H1 - the size of section of an electrode-wire with a covering

in a direction

of its submission (it is shown by an arrow); H2 - the size of

a wire

without taking into account a covering in a direction of submission

In [5] the mechanism of

process of electrocontact processing in liquid glass that has allowed to pass

to use instead of glass of suspension каолина without

deterioration of technological parameters of an electrocontact method is

opened. Now liquid glass became a scarce product as it, basically, is made in

Azerbaijan and is delivered in other countries. Except for that such working

environment is toxic and inconvenient in operation. The further researches will

allow to specify characteristics of suspension каолина and to begin systematic replacement with this environment of liquid

glass.

Electrochemical dimensional

processing

In the field of the

electrochemical dimensional and combined processing are carried out complex

researches on expansion of a scope of these methods at processing internal

surfaces [6] and large-sized turbine blades [7]. Positive results are reached

due to perfection of a design of the equipment, the tool and application of

operated pulsing current of a working environment. In connection with the

general slump in production and delay of rates of development of new aviation

products interest to the received in [6], [7] results has a little decreased,

though it is expedient to continue researches in a direction of research of new

working environments (electrolits without water, organic liquids) and in the

field of management of process of impulse-cyclic processing [8] under the technological

schemes offered by scientists of Tula, Ufa, Saint Petersburg, Voronezh.

In [7] the new way of

processing at which the watching system of the machine tool catches speed of

braking of a stream is offered and the working current is disconnected, but

pressure of electrolit in a backlash is kept. As the stream of a liquid in the

end of a cycle has not had time to be braked completely the working environment

continues to move along a backlash and bears colloid and gaseous products of

processing from interelectrode space.

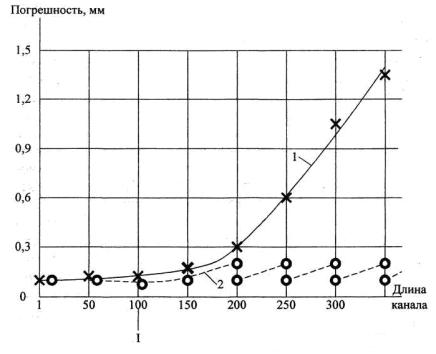

In figure 2 influence of a impulse

-cyclic mode of submission of electrolit on accuracy of processing of channels

in length up to 350 mm is shown.

Channel length, mm imprecision, mm

Fig. 2. The Error Of The

Lengthy Channel After Processing At Constant (a curve 1)

And Pulsing (a curve 2) Current

Of Electrolit

In figure 2 parameters for

channels with a length up to 350 mm are resulted. In case of constant current

of electrolit even at an interelectrode backlash 0,6мм (the recommended range of this parameter makes no

more 0,4-0,5мм) further there comes

"lock-out" of a stream a backlash a gas bubble and коллоидными hydrooxides. The error estimated as a

difference of average removing of an allowance (concerning an initial site) on

length of the channel, sharply increases and at limiting length than 1 mm

reaches more.

Application of a pulsing

stream (figure 2, a curve 2) enables to receive an error no more than 0,15-0,25

mm that answers specifications details with accuracy 8, 9 quality level.

Especially it is necessary to emphasize, that the increase in length of the

channel at pulsing movement of electrolit practically does not affect accuracy

of a detail (the error does not exceed 0,25 mm). The results resulted in figure

2, have allowed to specify recommendations at the choice of the bottom limit of

speed of submission of electrolit for lengthy channels. It makes from 3 up to 8

km/s (depending on an interelectrode backlash) though speeds up to 60 km/s

earlier were recommended, that demanded power-intensive hydraulic units with

pressure upon an input more than 2 MPa.

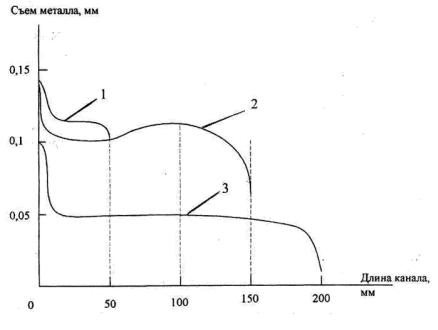

The length of a site of the

channel processable by one impulse depends on an interelectrode backlash

(figure 3).

Apparently from figure 1, the

limiting length of the processed site for one impulse at pulsing movement of

electrolit makes from 48-50 mm (at a backlash of 0,2 mm) where the greatest

takes place shall eat a material (about 0,12 mm), up to 180-200 mm (a backlash

of 0,4 mm). But in the latter case productivity decreases in 2-2,5 times.

In [7] the area of rational

use of a pulsing stream (table 1) proves.

Metal removing, mm Channel length, mm

Fig. 3. Material Removing From

A Heat Resisting Alloy For One Impulse At Backlashes: 1 - 0,2 mm; 2 - 0,3 mm; 3

- 0,4 mm.

Table 1

|

Typical Operations |

Schemes Of Processing |

The Characteristic Of A Stream |

Way Of Regulation Of A Stream |

|

|

On Pressure Upon An Input, An Output |

On A Cycle Removing An Allowance |

|||

|

1 |

2 |

3 |

4 |

5 |

|

Electrochemical Machining |

||||

|

1. An insertion of apertures |

Submission of an electrode |

Local uncontrollable pulsation without overlapping of a stream |

Рвх=const Рвых=0-0,01 МРа |

Is not used |

|

2. Processing of a feather blades greater dimensions |

|

|

|

|

|

1 |

2 |

3 |

4 |

5 |

|

- An insertion in an integral material |

Self regulation,

cyclic submission |

The Uncontrollable pulsation

with variable speed Is not used |

Calculation of average speed

and Рвх, Рвых |

Is not used |

|

-fair processing of a

structure |

Cyclic, with a variable

adjustable interelectrode backlash |

For greater blades a pulsing

stream with an opportunity of overlapping of current |

Calculation Vcp

Рвх=const |

Under the uniform law of

manage-ment of cycles of submission of a current and a working environment |

|

3.Manufacturing of cavities

of drop dies, molds with the big area |

Cyclic submission |

The Pulsing stream with an

opportunity of overlapping of current |

Calculation Рвх=const |

On speed gas-vapor a

component also I make |

|

4. Processing of channels of

various section of the big length |

|

|

|

|

|

Without submission of the

tool |

Motionless electrodes |

The Pulsing stream with

overlapping current |

The Settlement structure on

length of the channel Рвх =const |

On speed of phases and loop

variables of submission of a current |

|

zone processing |

With longitudinal submission

|

Poorly pulsing stream |

Calculation of average speed

of a stream, pressure on an input (Рвх =const) |

Is not used |

|

5.Turning round preparations

(disks, turbines etc.) |

Submission of the tool on a

screw line |

Pulsing (depending on

position) the tool |

Having watered a working

liquid |

The Dosed out

submission of a working

environment with a constant cycle |

|

The

combined processing |

|

|

|

|

|

1.With

guarantied channels hardening |

Longitudinal submission зонного an electrode tool under the law of a

constancy of longitudinal force of moving of the tool |

Pulsing with the period of

pulsations depending on an allowance on processing |

Calculation Vcp, Рвх, average speed of

submission of an electrode tool |

The

Dosed out submission of a working environment in a zone of processing with

management on speed of submission |

|

2. Deep an electroabrasive

grinding |

Submission along a surface

of preparation with регулируемой in the speed |

The Pulsing stream with the

cycle defined by the period of submission of a working environment |

Having watered of a working

liquid |

Dosed out submission,

changeable by quantity of an electricity, through the processing area |

The

note: Рвх - pressure of

electrolit upon an input in an interelectrode backlash; Рвых-противодавление

electrolit; Vcp - average speed of current of electrolit (it is

estimated under the average charge of a liquid)

Apparently from table 1, the

pulsing stream of electrolit is applied not only at electrochemical dimensional

processing (ECHO), but also in a combination with electroerosive, mechanical

process.

In table 2 the example of

processing обтекателя aerials of the

flying device from a variable (from 70 up to 180 mm) by width of a structure

and submission of a stream in the same direction is resulted.

On specifications on обтекатель the roughness of a surface after processing

should be no more Ra=1,25 a micron, an error up to ±0,5 mm. The traditional

method of processing with a constant stream of electrolit cannot provide these

parameters even at better preparation. The pulsation of a stream with the

period of anode dissolution 8-10 with has allowed to provide the parameters set

by the technical project on a detail.

Table 2

|

Way of processing |

The Mode of

processing |

The Roughness, mm |

The Error of a structure, mm |

||

|

Before processing |

After processing |

Before processing |

Before processing |

||

|

electrochemical with a constant stream |

The Astable stream of a working environment |

Rz=60-80 |

Ra=1-5 |

±1,0 |

±0,8 |

|

electrochemical with a variable

stream |

The Pulsing stream combined

with impulses of a current |

Rz=80-90 |

Ra=1-1,25 |

±1,0 |

±0,4 |

By scientific personnels of

Voronezh and Kazan are carried out researches of processes of electrochemical

dimensional processing in a non-stationary mode [9] and at low pressure that

allows to simplify and reduce the price of means of technological equipment

considerably. In view of the received results it is necessary to adapt the

developed methods for typical technological processes, in particular to apply

processing at low pressure in combined химикомеханических ways of

restoration of tooth gearings.

One of perspective directions

in the field of creation of the equipment and equipment for electrochemical

dimensional processing is application of drives (including for pulse moving an

electrode-tool) with use high (up to 60МПа) pressure of a

working environment [10]. It allows to reduce the sizes of drives and to expand

a zone of processing, including for large-sized details. Here the decision of

some questions on maintenance of tightness and reliability of highways, working

capacity of mobile elements of machine tools still is required.

Conclusions

1. The lead analysis of a

modern condition in the field of electroerosive and electrochemical dimensional

processing shows, that the reserve created earlier in this area of researches

allows to receive the new technological results expanding opportunities of

mechanical engineering on creation of competitive high technology production.

2. It is shown, that due to

management of a stream of electrolit it is possible to expand area of use of

electrochemical dimensional processing on lengthy details, having kept thus

high technological parameters, earlier achievable only for products with small

dimensions.

Cited literature

1. Kodencev S.N. Mechanism Of

Course Of Process Of Erosive-Thermal Processing Of Details // Nonconventional

methods of processing: collection of scientific

papers, Vol. 3. Moscow: Mechanical engineering, 2009. - 130-138 p.

2. Briskly A.F. Effective Technology

And The Equipment For An Electroerosive Insertion Of Precision Microapertures

// Belgorod:BSTU, 2010.-314 p.

3. Russian

patent № 2396153, The Way Of

Electroerosive Restoration Of Details From Steel Or Pig-Iron / V.P. Smolentsev, A.V. Bondar, A.N. Nekrasov, G.M.

Fatykhova // Bulletin 22, 2010.

4. Russian

patent № 2405662 The Way Of Drawing Of A Pig-Iron Covering On Aluminium

Alloys / V.P. Smolentsev, A.V. Grebenshchikov, A.V. Perov, B.I. Omigov // Bulletin

34, 2010.

5. Smolentsev

V.P. Physical Of A Basis And Technological Application Of Electrocontact

Process / V.P. Smolentsev, N.V. Sukhorukov // Voronezh: VPI, 1998. - 148 p.

6. Smolentsev

V.P. Technology Of Electrochemical Processing Of Internal Surfaces // Moscow:

Mechanical engineering, 1978. - 176 p.

7. Gazizulin K.M. Electrochemical

Dimensional Processing Of Large-Sized Details In Pulsing Working Environments

// Voronezh: VSU, 2002. - 243 p.

8. Zhitnikov V.P. Pulse

Electrochemical Dimensional Processing / V.P. Zhitnikov, A.N. Hare // Moscow:

Mechanical engineering, 2008. – 413 p.

9. Smolentsev G.P. Theory Of

Electrochemical Processing In A Non-Stationary Mode / G.P. Smolentsev, I.T. Koptev,

V.P. Smolentsev // Voronezh: VSTU, 2000. – 103 p.

10. Shipanov M.V. Designing Of

Highways Of A High Pressure For Industrial Equipment And The Electrochemical

Equipment / M.V. Shipanov, A.V. Kuzovkin // Fundamental and applied problems of

technics and technology, 2011, №5. - p.79-83