Ensuring electrical safety in the power industry

Seitkassym A., Dildabek D., Akilova K.

M. Kh. Dulaty Taraz State University

Electrical safety in industrial conditions is ensured by the appropriate

design of electrical installations: technical methods and means of protection; organizational

and technical measures.

Provision of electrical safety in Hydroelectric

power station, where high-capacity electric power is generated from

accidental contact with live parts is achieved by the following technical

methods and means used alone or in combination with each other: protective

shells, protective barriers (temporary or stationary); safe location of

current-carrying parts; isolation of the workplace; protective shutdown; warning

alarm; blocking; safety signs.

Locks are used in electrical installations that require frequent work on

the fenced live parts of the electric power industry. Locks on the principle of

action are mechanical and electrical. Mechanical have latches of different

designs, which lock the turning part of the mechanisms in the disconnected

state. They are used in electric starters, circuit breakers, circuit breakers.

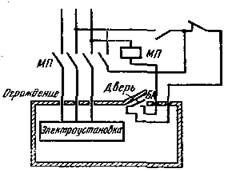

Electrical interlocks break the circuit with the help of special contacts

installed in the fence doors, covers and casing doors. These interlocks are

most advisable to use together with remote control of electrical installation

(Figure 1). In this case, the interlocking contacts (BC) are interlocked with

the door or lid, open or remove the supply circuit of the coil of the magnetic

beetle (MP). With such a circuit breakage of the control circuit and accidental

opening of the door is not dangerous, since the electrical installation will be

de-energized [1].

Figure 1. Diagram of an electrical interlock

In power plants, protective grounding, zeroing, shutdown, low voltage,

electrical separation of networks, isolation of live parts (working,

additional, reinforced, double), insulation monitoring, protective equipment

and safety devices are used to protect against touching metal non-conductive

structural parts of electrical installations.

Protective earthing is a deliberate electrical connection to the ground

or its equivalent of metal non-live parts that can be energized. It is an

effective protection measure for electrical equipment powered by voltage up to

1000 V from networks with isolated neutral. When the current-carrying parts are

closed on the equipment enclosure isolated from the ground, the latter will be

energized and touching it will be just as dangerous as the vase. Protective

earthing reduces the contact voltage to the housing to a safe level by reducing

the ground potential due to low ground resistance. The combination of metallic

conductors (grounding conductors) in direct contact with the ground and

conductors connecting electrical installations with earthing switches is called

a grounding device.

Depending on the location of the earthing switches, in relation to the

grounded earthing equipment, there are remote or concentrated, outline or

distributed. Earthing devices are natural and artificial. The natural include

various technological metal structures that have good contact with the ground,

reinforced concrete foundations, reinforcement of reinforced concrete

structures, metal cable sheaths (except aluminum), casing pipes, etc. For

grounding in the electric power industry, the available natural earthing

switches should be used first. Artificial earthing switches are specially

designed for earthing metal structures.

Grounding of electrical installations should be used in all cases at

voltage 380 V and above AC and 440 V and above DC, and also at voltages above

42 V, but below 380 V AC and 110 V DC in rooms with increased danger,

especially dangerous and in external electrical installations [1].

The objects to be grounded are connected to the grounding line with a

separate grounding conductor. Do not connect the earthing conductors from

several pieces of equipment consecutively, because in the event of a disruption

in the integrity of the connection, several electrical installations may be

ungrounded at once. The total resistance of the grounding device is equal to

the sum of the resistance to current flow from the earthing switches to ground

and the resistance of the grounding conductors.

To ensure safety, the resistance value of the grounding devices

according to the PUE should not exceed 4 ohms, and at a power of generators and

transformers of 100 kVA and less, the resistance of grounding devices is 10

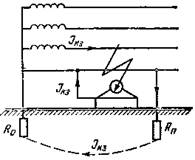

Ohm. In electrical installations up to 1 kV with a dull-grounded neutral,

zeroing must be performed. This method of protecting a person from electric shock

in the event of a phase closure on the non-conductive parts of the electrical

installation is a deliberate electrical connection with a zero protective

conductor (Fig. 2).

Figure 2. Zeroing

of equipment

The protective effect of zeroing is to reduce the duration of the short

to the housing and, consequently, to reduce the time of exposure of the

electric current to the person. When connecting the electrical enclosures to

the neutral wire, any short to the enclosure becomes a single-phase short.This

amount of current may not be enough to burn the fuse-link. In this case, the

body of the electrical installation will be under voltage, the value of which

may exceed the maximum permissible values for a person's touch

It is also unacceptable to use in a network with a deafly earthed

neutral the connection of a part of the electrical installations with zero wire

to parts earthed to separate earthing switches, since when the electrical

installations connected to a separate earthing switch are closed, the voltage

on it reaches a dangerous value. In this case, the enclosures of the electrical

installations correctly connected to the neutral wire will be under dangerous

voltage with respect to the ground.

Zeroing should quickly disconnect the damaged electrical installation

from the network and ensure the safety of the person's touch to the corps in an

emergency period. In accordance with this, the zeroing must be calculated for

the breaking capacity, as well as for the safety of contact with the housing

when the phase is closed to ground (neutral grounding calculation) and to the

housing (calculation of re-grounding).

Low voltage is the nominal voltage not exceeding 42 V, which is used to

reduce the risk of electric shock. In industrial conditions, the PUE provides

for the use of two small voltages - 12 and 36 V. Voltage up to 36 V is used in

rooms with increased danger, especially dangerous and outdoors for power of a

hand-operated electrified instrument, portable lamps. The voltage of not more

than 12 V inclusive must be used to power portable lamps in particularly

hazardous locations under particularly unfavorable working conditions: in

cramped conditions, when working with large metal grounded surfaces (working in

a metal container sitting or lying on a conductive floor, in a pit and other)

[1] [2].

Insulating coating of current-carrying parts or separating them from

other parts by a layer of dielectric in power plants ensures current flow along

the required path and safe operation of electrical installations. In electrical

installations, the following types of insulation are used: working, additional,

double and reinforced. Working is the isolation of current-carrying parts,

which ensures the normal operation of the electrical installation and

protection from electric shock. An additional is called insulation, which is

provided in addition to the working one to protect against electric shock in

the event of damage to it. Double insulation consists of working and additional

insulation. Reinforced - this is improved working insulation, providing the

same degree of protection as the double. In case of double insulation, in

addition to the main working part, an insulation layer is used on

current-carrying parts, protecting the person when touching metal parts that

are not live, which can be energized if the working insulation is damaged.

To ensure electrical safety in HPP as grounding device recommends first

of all using reinforced concrete foundations of industrial buildings. The

correspondence of their resistance to the permissible is determined by a

special calculation. The process of identifying this correspondence involves

the definition of the source data; calculation of the resistance of the

foundation; comparison of calculation results with acceptable resistance. In determining the initial data, the following

information is collected: the characteristics of the electrical installations

(type, types of main equipment, operating voltage, etc.); schemes and dimensions

of the reinforced concrete foundation of an industrial building along the outer

contour, limited by the basement parameter; specific electrical resistances of

the upper and lower layers of the soil [3].

In the power industry, personnel (not younger than 18 years old) who

have undergone medical examination, instruction and training in safe working

methods and who have a certain electric safety qualification group are allowed

to work for electrical installations.

Organizational arrangements that ensure safety when performing work in

existing electrical installations are the design of work by a dress or order,

admission to work, supervision during work, drawing up a break in work,

transferring to other jobs and finishing work [2] [3].

To ensure the safety of work in existing electrical installations with

partial or complete removal of voltage at workplaces the following technical

measures are performed:

• The necessary electrical installations or

parts thereof are switched off and measures are taken to prevent the supply of

voltage to the workplace due to errors or spontaneous switching on of

communication equipment;

• Prohibiting posters are posted and

temporary barriers are installed, if necessary;

• Portable grounding is connected to the

grounding bus and it is checked that there is no voltage on the live parts to

which the portable ground must be applied;

• Immediately after checking the absence of

voltage, grounding is applied to disconnect the live parts of the electrical

installation;

• The workplace is shielded and warning and

authorizing posters are posted [3].

Electric safety has always been and remains one of the

most important problems in the electric power industry. The alarming tendency

of the growth in the number of electro-injuries compared to the last decade is

due not only to problems in the electric economy of enterprises and

organizations (insufficiently high professionalism of electrical personnel,

non-compliance with norms and rules for work in electrical installations, poor

technical condition of electrical installations, etc.), but also a number of

objective reasons. One such reason is the fragmentation of large and

medium-sized enterprises with a well-established energy service and

well-functioning electric power in many small commercial organizations in which

the staff of electrical personnel is under-equipped and sometimes absent or

operates as part-time employees.

Bibliography:

1. GOST 12.1.019-2009. Occupational safety

standards system. Electrical safety. General requirements and nomenclature of

types of protection.

2. Fire safety rules for energy companies

(RD-153-34.0-03.301-00), M., "Energy Technologies", 2000.

3. Borisov L.G., Knyazevsky B.A., Kucheruk

S.M. Labor protection in power engineering. M., Energy Publishing House, 1985.