Òåõíè÷åñêèå

íàóêè/2. Ìåõàíèêà

Skoryk M. O.

National Technical University of Ukraine

“Igor

Sikorsky Kyiv Polytechnic Institute”

Complex cardboard packaging with a detailed modeling

and design process development

Cardboard has been and

remains the most accessible, low-cost and widespread packaging material, which

allows cardboard packaging to occupy the leading position in the structure of the

global packaging market.

The

analysis of methods and ways of improvement of cardboard packaging, designed

for storage and transportation of various products, demonstrates that the requirements

to the quality of modern cardboard packaging production are getting more and

more demanding, which, in turn, necessitates new technological solutions and

developments as a basis for design and creation of reliable cardboard packaging

[1]. The enforcement of requirements of

high quality cardboard production is an important factor that impacts the

process of design of elaborate cardboard packaging.

We

have analyzed the assortment of the market of cardboard packaging with

elaborate design, which allowed us to develop an improved cardboard packaging

technology that does not require adhesive binding as the construction stipulates

the system of shut-off elements, which allowed creating an integral sweep of

packaging without creation of separate additional elements, which in turn allows

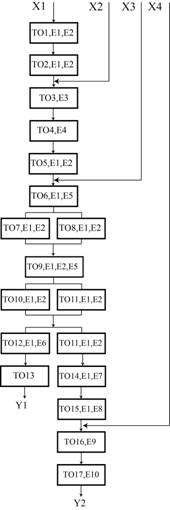

to bring down the prime price of finished cardboard packaging [3-4]. The corresponding process of pre-press preparation of a

cardboard package with elaborate design has been developed, presented in Figure

1 below, which provides a high quality of production in printing and post-printing

processes [2].

The

proposed technology for prepress preparation of cardboard packaging of

elaborate design includes the following technological operations and required equipment: Õ1 – input data and information about the future packaging (dimensions,

form, engineering drawing etc.); Õ2 – cardboard

for packaging Tambrite (GC2) 200 g/m2; Õ3 – vector images; Õ4

– printing plates

by AGFA: Azura TS, purifier by AGFA: Antura CtP Plate Cleaner, water,

protective colloid by AGFA: Antura CleanGum; Y1 – die-cut forms; Y2 – finished complete sets of printing plates; technologic operation 1 (ÒÎ1 and below) – development of package construction; Equipment 1 (E1

and below) – personal computer ARTLINE Business B27 v04, monitor

Philips 224E5QDAB/00; E2 – program suite Heidelberg Prinect

Package Designer 2016; ÒÎ2 – creation

of the package sweep; ÒÎ3 – package prototyping;

E4 – plotter for making layouts Lasercomb ASP 1600; ÒÎ4 – quality layout control

in accordance with requirements; E4 – metallic ruler 300 GOST 427-75; ÒÎ5 – corrections to the package

sweep and saving in TIFF format; ÒÎ6

– processing

of graphic images and creation of graphic registration of packaging; E5 – Adobe Illustrator ÑÑ; ÒÎ7 – imposition of the created graphic registration and package

sweep; ÒÎ8 – automatic creation of three-dimensional view of a package; ÒÎ9 – final quality control and corrections; ÒÎ10 – creation of a package

sweep on paper; ÒÎ11 – creating and saving

of file for making die-cut forms; ÒÎ12

– sending the file to the specialized firm making

die-cut forms; E6 – Internet; ÒÎ13 – getting die-cut forms; ÒÎ14 – electronic imposition

of a package sweep; E7 – Kodak Preps 6; ÒÎ15 – color separation and screening;

E8 – program

suite Adobe Photoshop CÑ, RIP EFI Colorproof

XF 3.1; ÒÎ16 – making printing forms using CtP-technology;

E9 – automated complex for making printing

forms using CtP-technology AGFA: Avalon N8-80; ÒÎ17 – quality control of printing forms; E10 – correcting pencils KP23-KP010-KP011,

overview table with illumination of 4500 Ê.

In conclusion, the suggested technology allows to develop and produce complex

cardboard packaging that meets the requirements of high-quality cardboard

production.

Figure

1. The technological

flow-chart of pre-press preparation of

the cardboard packing with elaborate design.

References:

1.

But,

O. Otechestvennyiy ryinok kartonnoy

upakovki v mirovom kontekste [ER] / Îlha But

// Mir upakovki.

– 2010. – ¹ 56. – Access: http://packaging.kiev.ua/rus/content/magazine/article/?id=85

2. Efremov, N. F. Konstruirovanie

i daziyn taryi i upakovki [Text] / N. F. Efremov,

T. V. Lemeshko. — M.: MGUP, 2004. — 424 p.

3. Krivoshey, V. M. Upakovka v nashomu zhittI [Text] / V. M. Krivoshey.

— K.: IATs «Upakovka», 2001. — 160 p.

4. Sirohman, I. V. Tovaroznavstvo pakuvalnih materIalIv I tari [Text]/ I. V. Sirohman, V. M. Zavgorodnya. –

K.: TsNL, 2005. – 614 p.