Ýêîíîìè÷åñêèå íàóêè/9. Ýêîíîìèêà ïðîìûøëåííîñòè

A. Chernyavs’kyy

Department of

special constructions of DPSK Ltd.

Economic potential of PCI technology in blast furnace production

Due to rise in the price of natural gas (mostly imported from

Metallurgical works of Ukraine will build utilities based on pulverized coal

injection (PCI) technology in 2-5 years with gross output about 7.5 million

tons. This will entail serious consequences for each metallurgical enterprise taken

separately as well as economy of

At least three problems can present difficulties in research of blast furnace

production economics nowadays.

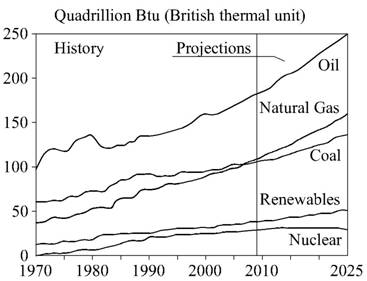

First of all research people must take into account macroeconomic trends

of world energy market as the key question that defines the strategy of consumers

[1, 8].

Saving rates of technological innovations as well as some technical

aspects are supposed to be the second significant issue [4].

The third problem is connected with manufacturing application of

pulverized coal injection (PCI) technology on selected metallurgical works [7].

World supply for coal is limited by 250 years of

production on current level, but the same value for oil production varies only from

35 to 50 years. Another forcible argument for using pulverized coal in blast furnace

production is that assured coal resources in

Fig. 1. World energy consumption

Gas production capacity of

Assured coal resources of

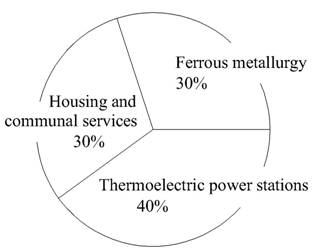

In the context of “Global strategy of

energy saving in

According to these programs, it is

planned to finish structural re-development of branch until

Metallurgical industry of

Fig. 2. Approximate structure of coal consumption in

PCI technology will completely exclude natural

gas from cast iron production process and also reduce coke rate by 23%. There will be considerable reduction in carbonic

acid atmospheric emission due to new technology.

Erection of utilities based on PCI technology requires sizeable

investments. The cost of mentioned utilities exceeds the cost of similar utilities

for liquid and gaseous fuel by a factor of 5 or 7. The most part of aggregate

investments (about 70%) meets liabilities of construction of pulverized coal

preparation and distribution workshops. Creation of large factories

specializing on pulverized coal preparation for several metallurgical works can

reduce capital inputs on construction.

Efficiency of pulverized coal use is

determined by quantity of injected pulverized coal fuel, coke replacement

factor, cost of fuel, capital expenditures and maintenance charges of pulverized

coal preparation and distribution facilities.

Principal questions of PCI system

creation decision-making are as follows [2, 3, 6].

1. What is the maximum possible consumption

of pulverized coal for each blast furnace in the nearest time?

2. What is the price of pulverized

coal fuel off-the-shelf for blast furnace production?

3. What is the payback period of PCI

equipment?

4. Finally, what is the efficiency of

using PCI technology?

Table 1

Planned pulverized coal

capacity by enterprise

|

Company name |

Capacity, million tons |

|

“Zaporizhstal JSC” |

2 |

|

“Alchevsk Metallurgical Works” |

2 |

|

“Mariupol

Metallurgical Works” |

2 |

|

“ |

1.2 |

|

“Donetskstal Plant”. |

0.3 |

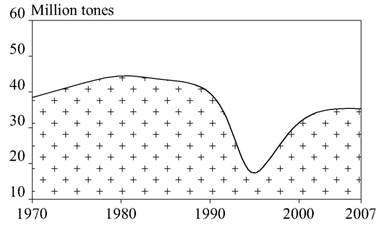

Using PCI technology on Zaporizhstal

JSC can bring considerable financial benefits in the nearest future [5].

It is planned to use PCI systems on 4 blast furnaces

of enterprise. Mentioned technology can reduce Zaporizhstal’s

consumption of natural gas by 335 million cubic meters a year or almost 100%.

The reduction in coke coal consumption will come to 330.6 thousand tones a year

or about 23%.

Fig. 3. Cast iron production volume, Zaporizhstal JSC

Investment structure is as follows:

- Zaporizhstal JSC

internal funds – 25%;

- special purpose crediting funds given by

European financial establishments – 75% (period of loan is 6.5 years).

Financial advantage of using PCI technology will

exceed 163 million UAH a year with planned payback period about 3 years.

Further research in the field of blast furnace production economics may

include detailed accounts of cast iron production process using enterprise

accounting data, process flowsheets etc.

References

[1] Endres A.,

[2] Fathutdinow R. (2002) Administrative

decisions. INFRA-M,

[3] Krichewsky M. (2005)

Intellectual methods in management. Piter,

[4]

[5] Kuz’menko N., Michailow N. (2003) Zaporozhstal:

a symphony of metal. Tandem, Zaporozhye.

[6] Vasilenko O., Shmat’ko V. (2003) Innovative management. CUL,

[7] Yaroshewsky S., Ryabenko

A. (1974) Application of powdered coal for cast iron smelting. Technika, Kyiv.

[8] Yatsenko A. Dubyniuk

Y. (2005) International markets of resources. CNL, Kyiv.