Òåõíè÷åñêèå íàóêè/2. Ìåõàíèêà

D.tech.scien. Artamonova E.N.

Saratov State Technical University n.a. Gagarin Y.A., Russia

Analysis of soil bases

In this paper the

conditions for the modeling of facilities' ground bases are summarized. In

some models the V.Z Vlasov – N.N Leont'ev theory of calculation for ground bases is used. It

based on the fundamental equations of mechanics and the solution of

differential equations for the expected draft at the point.

In this study, subgrade strength variability and flexible

foundation and

pavement designs are evaluated for reliability. Reliability is an important factor design to consider the

variability associated with the design inputs. Parameters such as mean, maximum

likelihood, median, coefficient of variation, and density distribution function

of subgrade strength are determined [1]. The approach is based on an extensive

literature review of current damage concepts included in current

mechanistic-based design procedures, soil permanent deformation laboratory data.

Design outputs are compared in terms of reliability and thickness using these

design procedures. It is shown that the provides higher reliability values

compared to the probabilistic procedure. All the existing subgrades fail

distress reliability such as rutting and top down cracking reliabilities.

Currently uses a single design P value to deal with variability associated with subgrade strength

design.

Is used to generate full scale subgrades

response and performance data for development and verification of subgrades

design criteria. The physical

properties of subgrades structures significantly influence both the response of

the subgrades to applied loads and the long-term performance.It is, therefore,

of the utmost importance that full scale test subgrades be constructed with

uniformity in material properties, layer thicknesses, and other considerations

for which non-uniformity might result in nonrepresentative and nontypical

behavior and failures [1]. Current mechanistic-based design methods for

the design of subgrades use vertical

strain criteria to consider foundation rutting.

A considerable number of measurements of the

physical properties test pavements were made at all stages of construction and

after construction was completed. The

measurements were made for three purposes: construction quality control,

construction acceptance, and material characterization. The material

characterization tests were performed to provide information for theoretical

modeling and were not related to construction and contractual

requirements.Tests were conducted on the subgrade materials, base subbase, and

surface layers. For

a basis of model building we take the model of elastic foundation, Vlasov - Leont'ev [1] (fig.1).

A considerable number of measurements of the

physical properties test pavements were made at all stages of construction and

after construction was completed. The

measurements were made for three purposes: construction quality control,

construction acceptance, and material characterization. The material

characterization tests were performed to provide information for theoretical

modeling and were not related to construction and contractual

requirements.Tests were conducted on the subgrade materials, base subbase, and

surface layers. For

a basis of model building we take the model of elastic foundation, Vlasov - Leont'ev [1] (fig.1).

figure 1

Here [2]:

u(x,y,z)=0; v(x,y,z)=0 ;

![]() (1)

(1)

![]() ;

; ![]() ;

;

D3=D1μ1+2Dk; Dk=Gh3/12.

Tests performed during construction consisted of

measuring insitu moisture content and

density. Tests were performed to characterize the variation of subgrade

strength with depth and over a tight horizontal grid. Width of the subgrade surface was divided into equally sized

quadrants and a location within each quadrant determined by randomly selected x

and y coordinates. The choice of

the appropriate type

of foundation is

governed by some important

factors such as: the

nature of the structure; the loads exerted by the structure;

the subsoil characteristics;

the allotted cost of foundations. Therefore to decide about the type of foundation,

subsoil exploration must be carried out. Then the soil characteristics within

the affected zone below the building should be carefully evaluated. The

allowable bearing capacity of the affected soil strata should then be

estimated. Theory of elasticity analysis indicates that the

stress distribution beneath footings, symmetrically loaded, is not uniform.

The actual stress distribution depends on the type of material beneath the

footing and the rigidity of the footing. For footings on loose cohesion-less

material, the soil grains tend to displace laterally at the edges from under

the load, whereas in the center the soil is relatively confined.It is shown in this study that single design strain value for a roadway section does

not yield an effective design regarding target reliability [2].

References:

1. Petrov V.V. Dimensional model of nonlinear deformable heterogeneous base // Interuniversity scientific collection.- Saratov: SSTU, 2007.- P.6-12.

2. Artamonova

E.N. On the design of slabs on the basis of a non-uniform // Moskau: INGN, 2012.- P.4.

In this paper we propose a

mathematical model of destruction (the relations connecting parameters

of efficiency at the time of fracture characteristics material), based on the

relationship of both these approaches to allow for the dependence of the

limiting critical conditions at which the destruction, the time of stress,

temperature environmental exposure, exposure, etc. This is especially typical

for polymers [1]. An examination of these experimental data one can draw

conclusions that should be taken into account when constructing the

mathematical correlations for the conditions of fracture:

Mechanical properties and the process of destruction of polymer

materials substantially depend on time and operating conditions.

Destruction is a two-stage process. At the first stage the

degradation of the properties of the material, the accumulation of damage,

microcracks occur. The stage ends at a time when the merger of microdamage

formed macroscopic crack. This moment is short-lived and by their physical

nature is a loss of stability of equilibrium microdefects.

Because of the irreversibility of

the process of destruction is determined not only the current values of

parameters characterizing it, but the entire prior history change of these

parameters.

Because of the private nature of the experimental data on the

effect of medium on behavior of plastic the composition of the general

mathematical for all materials the

phenomenological description of fracture based on mechanical ideas due to the

difficulties and serious shortcomings. Therefore it is necessary and the molecular interpretation

of macroscopic changes in the material. Thus, the phenomenological theory of

time dependence as would provide a common framework, which must fit the theory

of material behavior, and that put a detailed mechanical theory of change of macroscopic

and microscopic properties of the polymer. This need arises in the

interpretation of the parameters of the phenomenological equation, allowing you

to identify not only the common features, as well as the difference between the

materials.

Because of significant time effects for polymers the process of

their destruction more difficult than traditional materials, the phenomenon of

viscous and brittle fracture occur simultaneously. Fracture criterion in this

case must take into account the achievement σ, ε of the

instantaneous and destructive values σ

ð, ε ð, at the time tðàçð.,

and their dependence on the development of degradation of material properties ω (t).

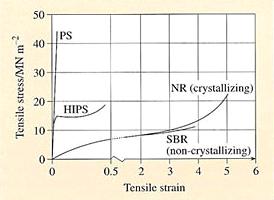

Figure

1.

Analysis of experimental data (Fig.1) suggests characteristics of

the temperature dependence of relaxation processes and fracture for

viscoelastic polymers with the same value of energy activation for each material.Both aspects of the strength of

polymers depend on the local structural changes that primarily can be linked

with the process of accumulation of damage, education grid hairline cracks.

Combining different approaches to describing these processes, i.e. formulation

of a general mathematical theory of deformation and fracture of polymers

depends on the study of the relationship of deformation, destruction and action

of strain, temperature, aggressive factors in the whole time interval of

operation of the element.

According the survey of the literary

sources for the analyzing of long-term durability of materials and elements

made of them two alternative approaches are basically exist: mechanical

(benchmarking) and kinetic.

According the first approach we

model the generalized condition for material destroying:

Ô

(θ1, θ2, θ3 ) = Ô ð.

Here Ô - the functional is some combination of the components of the stress or strain. The functional

Ô depends on the accepted theory strength or

given empirically and then the functional contains parameters determined

experimentally.

Ô = ∫dV [1/2 ρu?iu?i–

λ/2 ∂ui/∂xi ∂uj/∂xj - µ/2( ∂ui/∂xj

∂ui/∂xj +

∂ui/∂xj ∂uj/∂xj)].

1.The strain tensor can be

represented as a sum of tensors of elastic deformation of inelastic

deformation:

ε ij = ε

ij¹ + ε ij².

2. For description the strain state

and fracture in the framework of a generalized model of inelasticity is

necessary to consider the history of deformation of the sample depends on the

loading path and on time. For different loading paths for the processes of

varying duration results will be different.We give a physical explanation of

the above stated hypothesis.

References:

1. Suvorova J.V., Ohlson N.G., Alexeeva

S.I. An approach to the description of time-dependent materials //Materials and

Design, Vol.24. Issue 4, June 2003.- P.293-297.