A method for constructing a finite element model for

the calculation of reinforced concrete bending beam in the theory of deformation

model.

A.A. Suvorov, Scientific Consultant Ph.D. V.G. Murashkin.

FGFEI «Samara State University

of Architecture and Civil Engineering»

Abstract. The technique of creating a

plane finite element model for the calculation of reinforced concrete beam

bending it in the theory of deformation model. The calculation is in the

nonlinear formulation is taken into account creep of concrete and building load

in walking-iterative design process calculations. Performed simulations of

crack and the final state of the beam in a deformed state within is based on a

flat bend.

Key words: deformation model, flat

bend, nonlinear analysis, creep of concrete stress-strain diagram, function

curvature.

Simulation of beam

produced in the PC "Lira" version 9.6, which realized the possibility

of a nonlinear calculation taking into account the creep of concrete according

to the method of Eurocode 2 [1]. The problem of modeling has solved in flat

system «XOZ» elements such as beam-wall.

Fig. 1.0. Finite element model of reinforced concrete beam in the plane

problem PC "Lira".

As seen in Figure 1.0, the

beam was modeled in a longitudinal section with dimensions corresponding to the

actual dimensions of the structure, namely the section height - 220 mm; section

width - 120 mm; beam length - 1500 mm. Model

beam consists of four blocks: concrete beam body disposed above the reinforcing

bar, the contact area around the reinforcing rod, the rod itself valves Æ20The protective layer of the

concrete bottom. Load and communication have attached according to the design

scheme design.

The finite element mesh has

created from flat finite element (FE) beam-type wall to simulate plane stress. Geometric

dimensions TBE selected so that, firstly, the cross section corresponds to a

cross section model of the actual sample, secondly, has provided acceptable

precise position (height) of the crack tip, as well as the ability to analyze

the stress-strain state of the concrete in the zone his contact with the valve.

Concrete is modeled from

physically nonlinear finite element rectangular plane problem number 221 5 mm

along the axis «Z», and 10 mm along the axis "X" with the task of

stiffness characteristics for concrete class B30 (type "TA" - natural

hardening). The width of the data elements in the space for concrete, located

above and below the rebar is the real width of the beam section.

Contact zone reinforced

concrete is modeled by three thin layers of a thickness of 1 mm and a width of

10 mm TBE. The first (internal to the rebar) layer is modeled physically

nonlinear finite element rectangular plane problem number 281 (ground) with the

task of further traction, angle of internal friction, limiting tensile strength

for concrete contact zone. The second and third (external to the rebar) layers

are physically non-linear finite element rectangular plane problem number 221

with the characteristics of the material according to CE concrete. The width of

the contact zone is modeled equal![]() - semi perimeter corresponding reinforcing bar in order to get the

shear stresses corresponding to the actual contact surface. The presence or

absence of coupling is modeled respectively the presence or absence of elements

adjacent directly, facility to the reinforcing rod. When you reach the contact

tangential stresses the limits that have been taken to be 2Rbt,

interaction with concrete reinforcement is modeled as follows. Adjacent to the

reinforcing bar element in which the shear stresses have reached the limit

values destroyed, and to the reinforcement and concrete are

applied opposing force

- semi perimeter corresponding reinforcing bar in order to get the

shear stresses corresponding to the actual contact surface. The presence or

absence of coupling is modeled respectively the presence or absence of elements

adjacent directly, facility to the reinforcing rod. When you reach the contact

tangential stresses the limits that have been taken to be 2Rbt,

interaction with concrete reinforcement is modeled as follows. Adjacent to the

reinforcing bar element in which the shear stresses have reached the limit

values destroyed, and to the reinforcement and concrete are

applied opposing force![]() equal:

equal:

![]() (1.0)

(1.0)

where lk- length of the finite element.

The body of the

valve has created by physically nonlinear finite element rectangular plane problem

number 221 with the dimensions of 20 mm along the axis «Z», and 10 mm along the

axis "X" with the task of reinforcement stiffness characteristics for

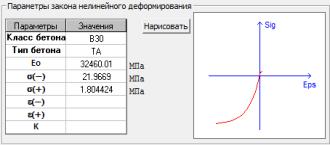

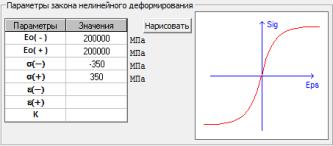

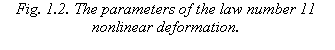

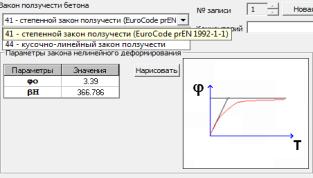

class A400. Deformation law has adopted for the main concrete and concrete

contact zone under number 21 - Exponential (standard strength) (Fig. 1.1.). For

valves - 11th exponential law of deformation with the task to design resistance

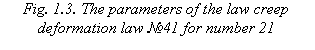

strength of the steel [2] (Fig. 1.2.). In a further menu (Figure 1.3) for the

stiffening of concrete parameters are set taking into account creep, calculated

by the algorithm in the environment «Mathcad» according to block coefficient

calculation creep in the Annex to Eurocode 2 [1].

The body of the

valve has created by physically nonlinear finite element rectangular plane problem

number 221 with the dimensions of 20 mm along the axis «Z», and 10 mm along the

axis "X" with the task of reinforcement stiffness characteristics for

class A400. Deformation law has adopted for the main concrete and concrete

contact zone under number 21 - Exponential (standard strength) (Fig. 1.1.). For

valves - 11th exponential law of deformation with the task to design resistance

strength of the steel [2] (Fig. 1.2.). In a further menu (Figure 1.3) for the

stiffening of concrete parameters are set taking into account creep, calculated

by the algorithm in the environment «Mathcad» according to block coefficient

calculation creep in the Annex to Eurocode 2 [1].

Cracks are modeled jointing nodes in the development

of normal cracks. A method of modeling crack conducted according to the calculation

of crack opening width [1] and their development is in accordance with the

position of the main areas of tensile stresses that can more accurately

simulate the stress state of the concrete at the crack tip and to determine its

depth.

Cracks are modeled jointing nodes in the development

of normal cracks. A method of modeling crack conducted according to the calculation

of crack opening width [1] and their development is in accordance with the

position of the main areas of tensile stresses that can more accurately

simulate the stress state of the concrete at the crack tip and to determine its

depth.

For inclusion in the work of

these laws, nonlinear deformation produces a nonlinear load. In the nonlinear

static load, uploading has used in accordance with the design scheme design.

The number of steps of the load has selected independently. In the appropriate

boxes on settlement, periods creep of concrete specified n-th day since the

control of the load. The number of iterations - 300 [4].

When loading the beam is

considered appropriate n-th time period to attend the element creep of

concrete. In one of the sections where tensile stresses ultimate tensile

concrete in bending, reaching values of 1,75 Rbt, is

formed crack normal process of development which, in accordance with the

vertical trajectory of principal tensile stress is simulated serial jointing

nodes of the finite element from the lower edge of the side of the compressed

zone. Allowable precision overlay cracks according to calculations by Eurocode

2 was established and modeled on the sites of the principal stresses. The

position of the crack tip height section is set such that the principal tensile

stresses at the crack tip were equal or close to Rbt. After

determining the position of the crack tip is analyzed magnitude of tangential

stresses in the contact area and the elements (adjacent to the reinforcing

bar), in which the voltage reaches the limit (2Rbt), are eliminated,

and the interaction of reinforcement and concrete is simulated as mentioned

above, the application of oppositely directed efforts Nt. At the same time, as the destroyed adjacent to the

valve CE, controlled the main tensile stresses at the crack tip and, if

necessary, adjusted her position. Set out the process of development of the

crack, flowing at a constant load, corresponding to the moment of its

formation, continues as long as the shear stresses in the contact zone and the

normal stresses at the crack tip will no longer exceed 2Rbt and Rbt

respectively [3].

As determined by the point

of zero relative displacements reinforcement and concrete, and adjusted its

displacement. Moving the contact layer of concrete and reinforcement at zero

mutual displacement together, which allows its location to correct the error,

since it may be between the member nodes.

REFERENCES

1.

BRITISH STANDARDS INSTITUTION. BS

EN 1992-1-1, Eurocode 2: Design of concrete structures. General rules and rules

for building. BSI, 2004.

2. SP 63.13330.2012. Concrete and reinforced concrete

structures. The main provisions. The updated edition of SNIP 52-01-2003. Moscow, 2012.

3. A.A. Prokopovych

Bending resistance of reinforced concrete structures with different conditions

clutch armature with concrete. Samara, illegal armed groups "SMS",

2000.

4.

V.G. Murashkin, D.A. Panfilov, A.A. Suvorov.

Modelling of reinforced concrete beam finite element method taking into account

the creep of concrete / Tradition and Innovation in Building and Architecture:

Materials 70th Anniversary All-Russian Scientific and Technical Conference on

the results of R & D 2012 - Samara, 2013 - p. 307-308 - Part2